方案详情文

智能文字提取功能测试中

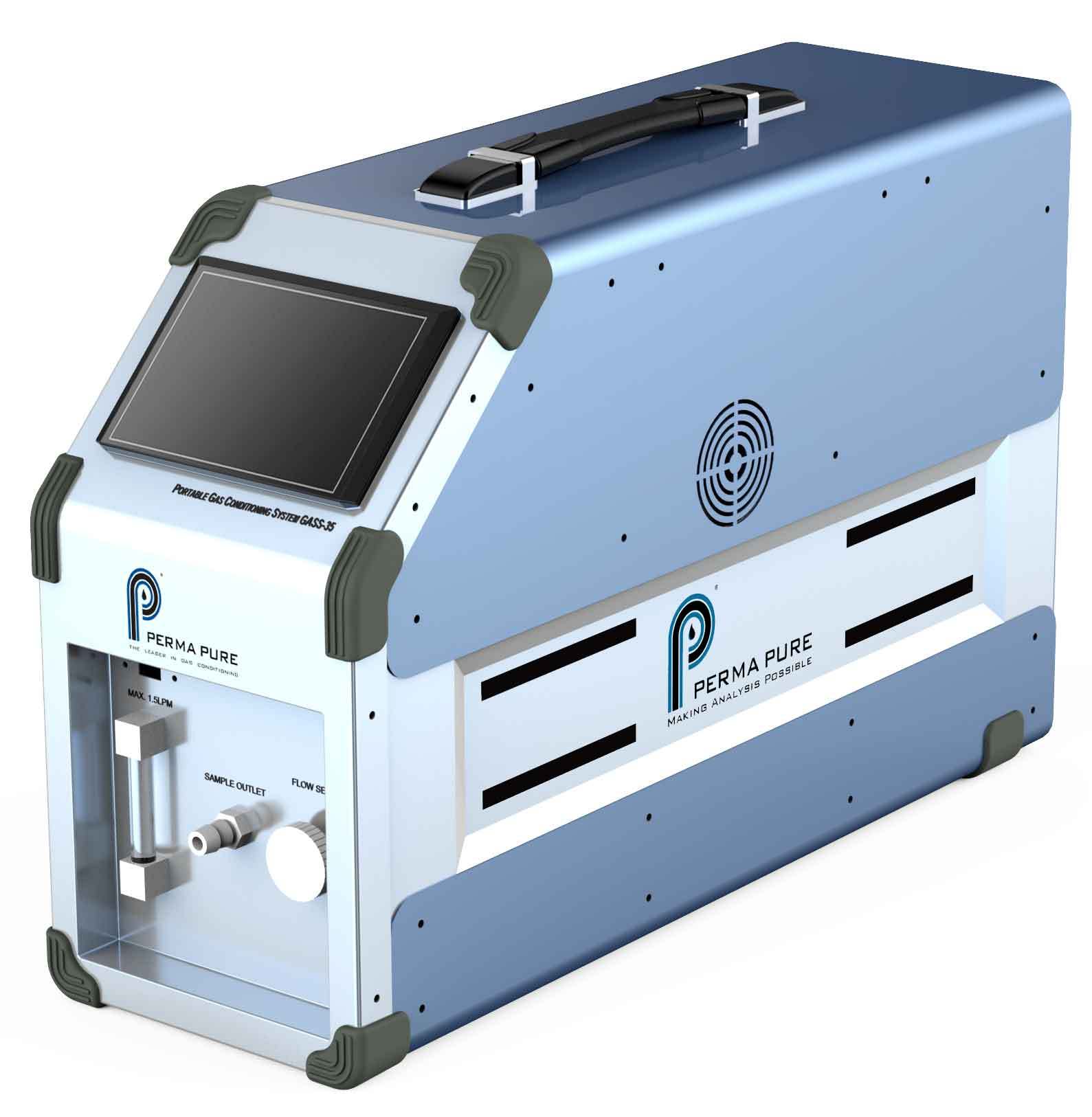

GASS-35 Portable Flue Sample Gas Conditioning SystemPerma Pure LLC USA HeadquartersTelephone: 732-244-0010 Toll Free: 800-337-3762Fax: 732-244-8140Address: 1001 New Hampshire Ave. Lakewood, NJ 08701 USAA HALMA COMPANY GASS -35 Portable Flue Gas Conditioning System Applicable to conditioning for portable optical and electrochemical analyzersunder high humidity and low SO2 flue gas Remove water vapor in gas phase by Nafiontubing to improve analysis accuracy Stable operation, suitable for high- andlow-temperature operational environment Light and strong frame, suitable for carrying The Perma Pure GASSTM-35 portable conditioning system adopts Nafion° drying tube technology to remove moisture fromsample gas, enabling accurate analysis of low SO2 in high humidity sample, while not requiring any external connection ofpurge gas. There is no generation of condensate water during dehydration. The sample gas flow rate can reach 2.0 LPM (at 1.5 LPM, the flue gas with water content ≤30% V/V can be conditioned). Thedew point of the sample gas after conditioning can be lower than 0℃, which prevents the dissolving loss of low-concentrationSO2 (<35mg/m3) during condensation and dehydration, to ensure measurement stability and accuracy by portableanalyzers (including optic and electrochemical analyzers) in the high humidity and low SO range, while ensuring highermeasurement response speed. The GASSTM-35 system is light-weight and strong with a net weight of 11.5kg, making it easy to use for portable applications. Itcan be stably operated at ambient temperature ranges of 50℃ to-10℃. The GASSTM-35 portable conditioning system issuitable for use with portable non-dispersive infrared and electrochemical analyzers commonly used in the market, and solvesthe problem of SO2 loss and other problems caused by the generation of condensate water. Product applications ■Portable analysis of flue gas for SO and NO after“UItra-low Emission” Portable flue gas analysis of SO2 after wet flue gas desulfurization(WFGD) Portable flue gas analysis of SO and HCl at the vent of solid waste in anincineration plant Temporary dehydration backup system for Ultra-low emission CEMSsystems during repairs to, or replacement of, fixed CEMS unit Technical Specifications Maximum sampling flowrate: 2LPM Normal sampling flowrate: 1.5LPM Max. Humidity rate 30% V/V Sampling negative pressure: -10Kpa Warm up time: <30min Off time: 15min Highest temperature of 180°C sample gas at the inlet: Dew point of sample gas at the outlet: ≤0°C (Ambient Temp. below 40°℃) s4°C (Ambient Temp. 40°C-50°C) Maximum pressure of sample gas at the inlet: 103.4kPa Data storage: Temp. Dew point data real-time storage, USB Interface Inlet/Outlet fitting size: 1/4”FPT Electrical requirements: 220 VAC, 2 amps, 0.4 kW Enclosure: Spray coating steel shell Weight: 11.5kg (package excluded) Dimension: 550mmx370mmx190mm Working environment: -10°C to 50°℃ air environment Accessories: 0-95% relative humidity Altitute reaches 2,000 meters High temp. sampling probe+heating cable Temp. control range 150°C-180℃ Available Markets: Flue gas monitoring manual comparison for Environmental Monitoring Department Flue gas monitoring manual comparison for Third Party Testing Organization Environmental protection scientific research project of flue gas monitoring in Scientific research units,colleges and universities The condenser of CEMS system temporarily repair/replacement Portable"back-up”gas conditioner for use during repair/replacement of fixed CEMS units Email: info@permapure.com Perma Pure India Pvt. Ltd. ( Mobile: +919910098244 Email: srai@permapure.com Address: Plot No. A-147, Road No. 24, Wag l e Industrial Estate,Thane (West)- 400604, M a harashtra, India ) 案例摘要中国的大气污染属于典型的燃煤型污染,以粉尘,光化学烟雾和酸雨危害最大,酸雨的问题实质就是SO2污染问题。然而,在燃煤电厂烟气监测手工比对现场却会因为烟气中的水汽会将易溶于水的SO2溶解,导致SO2监测数据不准确或监测不到。严重时,溶于水的SO2会形成酸,将昂贵分析仪中的气室腐蚀,造成巨大损失。太原某第三方检测机构问题火电厂采用煤炭做主要燃料进行发电,在燃烧的过程中产生大量的SO2和NOX等废气,其中SO2排入大气会产生污染形成酸雨。当前火电厂主流脱硫技术是湿法脱硫技术,由于在脱除的过程中加入了大量的水,造成烟气中水分含量非常高。在烟气监测中,未被脱除的SO2随着高温高湿的烟气一起被采样探头抽取,当高温高湿烟气进入冷凝器由于温度下降在冷凝器中有液态水析出,冷凝水将SO2溶解产生亚硫酸。造成SO2测量值偏低或为零,甚至酸雾进入分析仪直接腐蚀分析仪气室,造成光强损失,分析仪产生漂移等。博纯解决方案在现场比对应用中,博纯会提供GASS®-35便携式预处理系统方案。GASS® 35系统采用气态除水的Nafion®干燥管技术,在现场无需任何外接反吹气源,就可以处理高湿度、低SO2的超低排放烟气,除水全程中无任何冷凝水析出,除水效率达96%以上,样气露点远远低于4℃。GASS®-35烟气处理流量可达≤1.5 LPM (在1 LPM时,可处理≤30% V/V水份含量的烟气)。处理后烟气露点低于4℃,避免了低浓度SO2(< 35mg/m3)在冷凝除水过程中的溶解损失,确保便携式分析仪(包括光学、电化学等机理的分析仪)在高湿度、低SO2量程情况下的测试稳定性和准确性,还具有较高的测试响应速度,最终保证了电厂排放污染物监测数据更加接近真实数值。进行过手工比对,SO2数据如下机组1机组21. S**3080(NDIR)+GASS-3512~15mg/m342mg/m32. S**3080(NDIR)+冷凝器0.86mg/m38.3mg/m3产品解决方案的优势:比起冷凝器解决方案,GASS-35可用于-10至50℃的复杂温度环境中无易碎的冷凝瓶,运输方便除湿率高,30%V/V条件下可达96%以上

关闭-

1/2

-

2/2

产品配置单

美国博纯有限责任公司上海代表处为您提供《燃煤电厂烟气中SO2检测方案(烟气分析仪)》,该方案主要用于燃煤电厂烟气中SO2检测,参考标准《暂无》,《燃煤电厂烟气中SO2检测方案(烟气分析仪)》用到的仪器有GASS-35便携式烟气分析预处理系统。

我要纠错

推荐专场

烟气监测(CEMS)/烟气分析仪

更多相关方案

咨询

咨询