聚合物薄膜中聚合物薄膜的玻璃化转变温度的测量检测方案(白光干涉测厚)

检测样品 电子元器件产品

检测项目 聚合物薄膜的玻璃化转变温度的测量

方案详情文

智能文字提取功能测试中

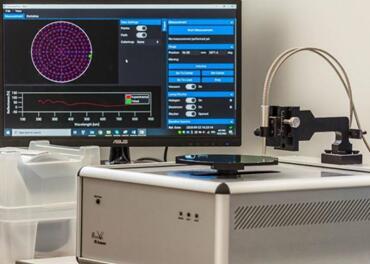

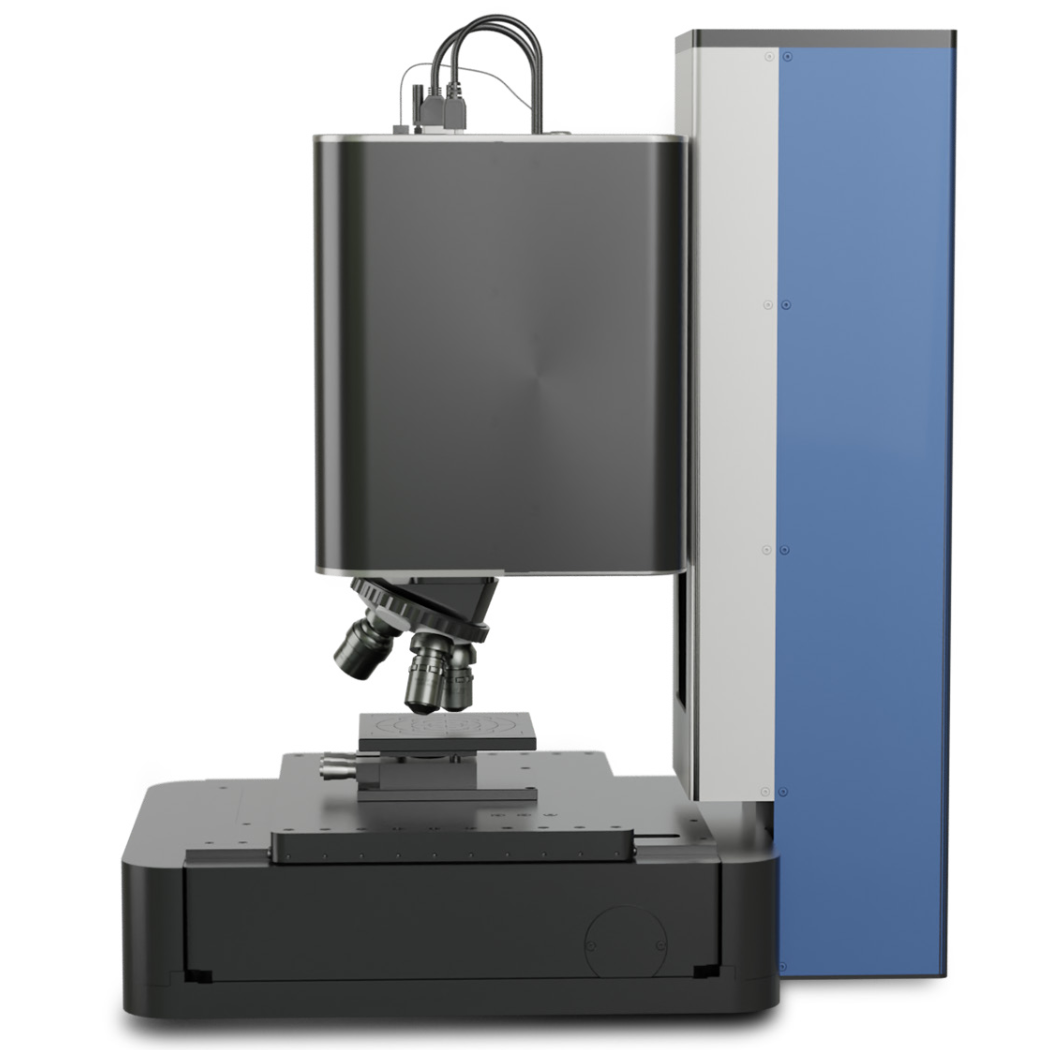

Film Metrology & More...For further information please contact us at info@thetametrisis.com or sales@thetametrisis.comThetaMetrisis @ 2014, www.thetametrisis.com ThetaMetrisis APPLICATION NOTE #013 Simultaneous Real-time monitoring of film thickness andrefractive index during thermal processing Goal: The determination of glass transition temperature of polymeric films through the real time monitoringof thickness and refractive index of the film during thermal processing. Means & Methods: An FR-Thermal VIS/NIR configured to operate in the 360-1000nm spectral range is used.The hot plate integrated on the tool, is controlled either manually or through the FR-Monitor software. In thepresent case the thickness and the refractive index (Cauchy model) of the film are monitored during theheating at a constant rate. The polymers investigated were poly(iso-butyl methacrylate) (PiBMA), poly(n-propyl methacrylate) (PPMA) and poly(ethyl methacrylate) (PEMA) and their films are spin coated on siliconwafers. Prior to the measurements the samples have been Post Apply Baked at 145°℃ for 15min. Results: The heating rate is a 2-3℃/min and the polymeric film thickness and the refractive index aremonitored at 50 measurements / min and both parameters are plotted vs. temperature, figs. 1a-c. Clearly thepolymeric film thickness increase linearly with temperature at two temperature regimes. The intersect point ofthe extrapolated linear sections is defined as the grass transition temperature (Tg) of the polymer.The Tgvalues for these poly(alkyl methacrylate) films were found to be in agreement with the literature. The thickness increase rate is in good agreement with the reported values in the literature of thermalexpansion coefficient at each polymer’s "rubbery phase" i.e. at temperature values higher than Tg and in thesame order of magnitude with the reported values in the "glassy phase". Figure 1: Thermal treatment of methacrylate films and monitoring of film thickness and refractive index a) PiBMA, b)PBMA,c) PEMA. The calculated values of thermal expansion coefficients, depending on the temperature range,are : (i)2.9-3.4*10° for T

-

1/1

产品配置单

迈可诺技术有限公司为您提供《聚合物薄膜中聚合物薄膜的玻璃化转变温度的测量检测方案(白光干涉测厚)》,该方案主要用于电子元器件产品中聚合物薄膜的玻璃化转变温度的测量检测,参考标准《暂无》,《聚合物薄膜中聚合物薄膜的玻璃化转变温度的测量检测方案(白光干涉测厚)》用到的仪器有扫描型光学膜厚仪 FR-Scanner、进口纳米狭缝涂布机、多功能桌面式ALD原子层沉积系统AT610。

我要纠错

推荐专场

白光干涉测厚仪

更多相关方案

咨询

咨询