方案详情文

智能文字提取功能测试中

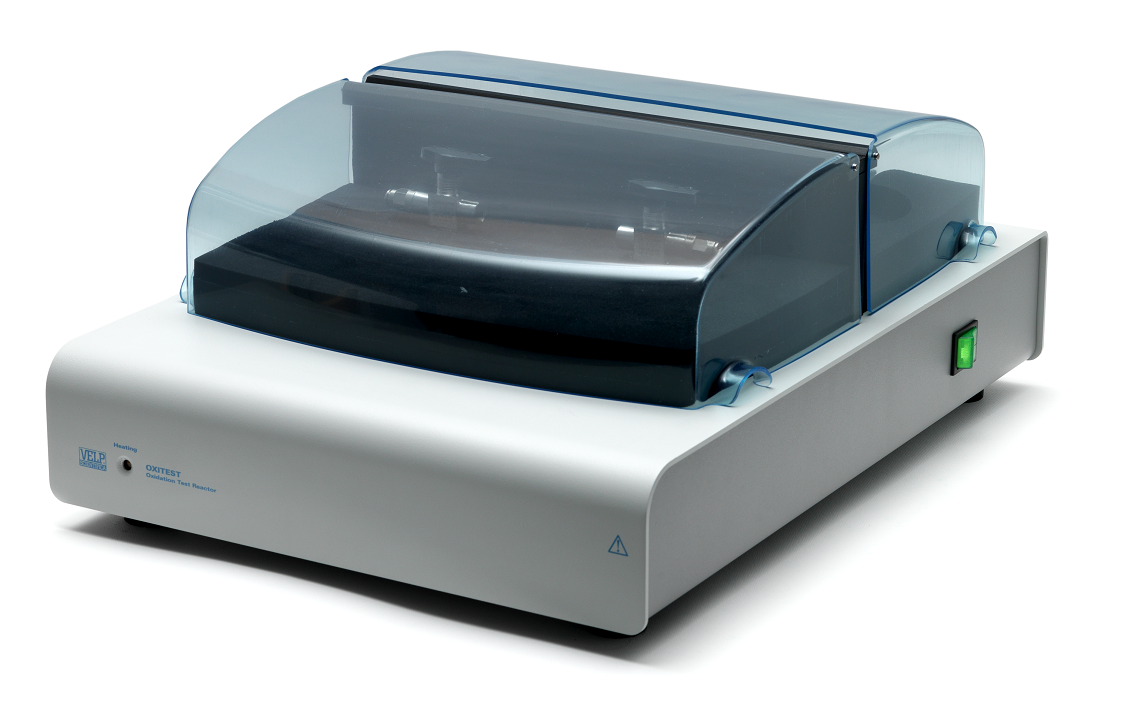

APPLICATION NOTEF&F-0-001-2014/A1 OXIDATION STABILITY OF BUTTER Oxidation Stability of Butter Reference: International Standard Procedure AOCS Cd 12c-16 Tested with VELP Scientifica OXITEST Oxidation Stability Reactor (Code F30900248) Introduction Butter is an emulsion of water in oil, approximately composed by 80% of fat. In good butter the moisture is evenlydispersed throughout the butter in tiny droplets. Butter can be made from either whole milk or cream; however, it is moreefficient to make butter from cream. Traditionally, it can be fermented or, in Anglo-Saxon countries, salted before trading. It is used as a condiment and incooking, similar to vegetable oils and lard. The sensorial quality of butter can be described as the customer’s reaction to its color, texture and flavor. It has beensaid that the consumer tastes with his/her eyes, and it is true that a person's initial impression of a food will often bedeterminant. Apart from food, it can be found as an ingredient of cosmetics, medicines and lubricants. Oxidation Stability of Food One of the most important quality alteration of food is due to oxygen absorption by the unsaturated fatty acids, free oresterified. The auto-oxidation of fats is a chemical reaction promoted by light, high temperatures, metal traces and,sometimes enzymes. OXITEST can determine the oxidation stability of various sample types, without the need for preliminary fat separation OXITEST Principle OXITEST speeds up the oxidation process because of the two accelerating factors, temperature and oxygen pressure,according to the most common applications. The instrument measures the absolute pressure change inside the two chambers, monitoring the oxygen uptake byreactive components in the sample and automatically generates an IP value. IP Definition: IP stands for Induction Period and it is the time required to reach the starting point of oxidation, corresponding to either alevel of detectable rancidity or a sudden change in the rate of oxidation. The longer the Induction Period, the higher the stabilityagainst oxidation over time. Sample Butter formula F1 Fat labeled value: 81.0 g / 100 g Butter formula F2 Fat labeled value: 82.0 g / 100 g Equipment and Chemicals Analytical balance, 3 decimals ●· Silicone grease ●Oxygen, purity grade 5.0 Sample Preparation Keep the samples refrigerated during the storage. Put 10 grams of homogeneous sample directly on the surface of the titanium sample holder, by using a spatula. In each reaction chamber (A and B), place 1 sample holders (containing the sample) and 2 spacers. Analysis Procedure Grease the O-rings with silicon grease and set them in their position. Close the chambers with the titanium covers andturn the discharge valves in open position. Set the following conditions on the OXISoft TM software: Temperature: 80°C Oxygen Pressure: 6 bars . When the temperature set is reached inside the chambers, close the discharge valves and start loading oxygen. Data acquisition is automatically started by the software. Typical Results on Butter Each sample has been monitored four times. At the end of the oxidation tests, the IP of every run is calculated by thesoftware OXISoftTM. lt is possible to elaborate the oxidation curves obtained for each kind of butter. Sample Weight (g) Set Point (bars) Set Point (°C) IP (hh:mm) Line Butter F1 10,000 6,00 80,0 35:28 Butter F1 10,000 6,00 80,0 36:54 Butter F1 10,000 6,00 80,0 35:44 Butter F1 10,000 6,00 80,0 36:14 Butter F2 10,000 6,00 80,0 46:24 Butter F2 10,000 6,00 80,0 48:35 Butter F2 10,000 6,00 80,0 46:17 Butter F2 10,000 6,00 80,0 48:00 5,5- 5- 4,5 4- Repeatability Test With OXISoft , it is possible to create a repeatability test for each analysis, in order to obtain the average, standarddeviation and relative standard deviation of the results. For repeatability test, it is necessary to analyze the same quantity of the sample in duplicate or more, at the same valuesof temperature and pressure.In the table below the results are summarized: Sample IP average (hh:mm) SD (hh:mm) RSD% Butter F1 36:05 0:37 1.7 Butter F2 47:19 1:09 2.4 RSD value must be <5% in order to obtain good results. Formula Comparison With OXISoftTM, it is also possible to easily compare the obtained IP values, of different formulations but tested at thesame condition, and identify the most stable one. Butter F1 Butter F2 Conclusion The results obtained by OXISoft and the formula comparison function, clearly discriminate the butter’s resistance tooxidation. Butter F2 results significantly more stable against oxidation Although the total fats percentage is very similar, Butter F1 has a shorter IP value, hence a lower oxidation stability. Thisis probably related to their fat composition: higher content of unsaturated fatty acids has a higher oxidation kineticcompared to saturated fatty acids as shown in table below. Comparison between the rate of oxygen absorption by saturated and unsaturated fatty acids Stearic acid 1 Oleic acid 11 Linoleic acid 114 Arachidonic acid 179 Table bibliography:“Food Chemistry"-page 166-Cappelli, Vannucchi Butter is an important ingredient in food industry and, knowing its stability, can help to choose it in making end product'sformulation. Benefits ofOXITEST are: Test is made directly on the whole sample No need for preliminary fat separation of the sample Resistant titanium chamber Time saving analysis, if compared to the traditional methods Especially designed for R&D, Product Development and Quality Control labs Many investigations available through the software OXISoftTM: 1. Repeatability test: a series of tests run on the same sample or standard to verify its IP period, to calculateaccuracy and repeatability of the data 2. Freshness test: to verify the quality of different lots, for example of the same raw material, and compare them 3. Formula comparison: to identify the most stable formula of a finished product, under the same conditions 4. Packaging comparison: for testing which packaging maintains the product in the freshest condition 5. IP during ageing: to obtain a graph of the decrease of the product IP during the shelf-life period 6. Estimated shelf life: to have a prediction of oxidation stability during the shelf life. 黄油是由水和油组成的乳剂,大约由80%的脂肪组成。在优质黄油中,水分以小滴均匀地分散在整个黄油中。黄油的感官质量可以描述为顾客对其颜色、质地和味道的反应。除了食品,它还可以作为化妆品、药品和润滑剂的成分。黄油是食品工业中的重要成分,了解其稳定性有助于在制作最终产品配方时选择黄油。食品最重要的质量变化之一是由不饱和脂肪酸吸收氧气、酯化。脂肪的自动氧化是一种由光、高温、金属,有时还有酶促进的化学反应。 OXITEST可以测定各种类型样品的氧化稳定性,而不需要进行初步的脂肪分离。根据最常见的应用,OXITEST加速氧化过程是因为温度和氧气压力这两个加速因素。该仪器测量两个腔室内的绝对压力变化,监测样品中反应组分的吸氧,并自动生成IP值。 IP定义:IP代表诱导期,它是到达氧化起始点所需的时间,对应于可检测的酸败程度或氧化速率的突然变化。诱导期越长,抗氧化稳定性越高。实验样品:Butter formula F1Fat labeled value: 81.0 g / 100 gButter formula F2Fat labeled value: 82.0 g / 100 g实验仪器:意大利VELP 油脂氧化分析仪实验结果:每个样本都被监测了四次,在氧化测试结束时,每次运行的IP由OXISoftTM软件计算,可以详细地描绘每种黄油的氧化曲线。OXITEST的好处是:·直接对整个样品进行测试·无需对样品进行初步脂肪分离·耐钛室·与传统方法相比,节省时间的分析·专为研发,产品开发和质量控制实验室设计·通过OXISoft™软件可获得的许多结果:1. 重复性测试:在同一样品或标准上运行的一系列测试,验证其IP周期,计算数据的准确性和重复性2. 新鲜度检验:验证不同批次(如同一原料)的质量,并进行比较3.配方比较:确定在相同条件下一个成品中最稳定的配方4. 包装比较:用于测试哪种包装能使产品保持在最新鲜的状态5. 老化期间IP:获取产品在保质期内IP下降的曲线图6. 估计保质期:对保质期内的氧化稳定性有一个预测。

关闭-

1/4

-

2/4

还剩2页未读,是否继续阅读?

继续免费阅读全文产品配置单

北京盈盛恒泰科技有限责任公司为您提供《黄油中氧化稳定性检测方案(食用油品分析)》,该方案主要用于食用油脂制品中理化分析检测,参考标准《暂无》,《黄油中氧化稳定性检测方案(食用油品分析)》用到的仪器有VELP-油脂氧化分析仪OXITEST、意大利VELP公司-食品油脂氧化分析仪。

我要纠错

推荐专场

相关方案

咨询

咨询