方案详情文

智能文字提取功能测试中

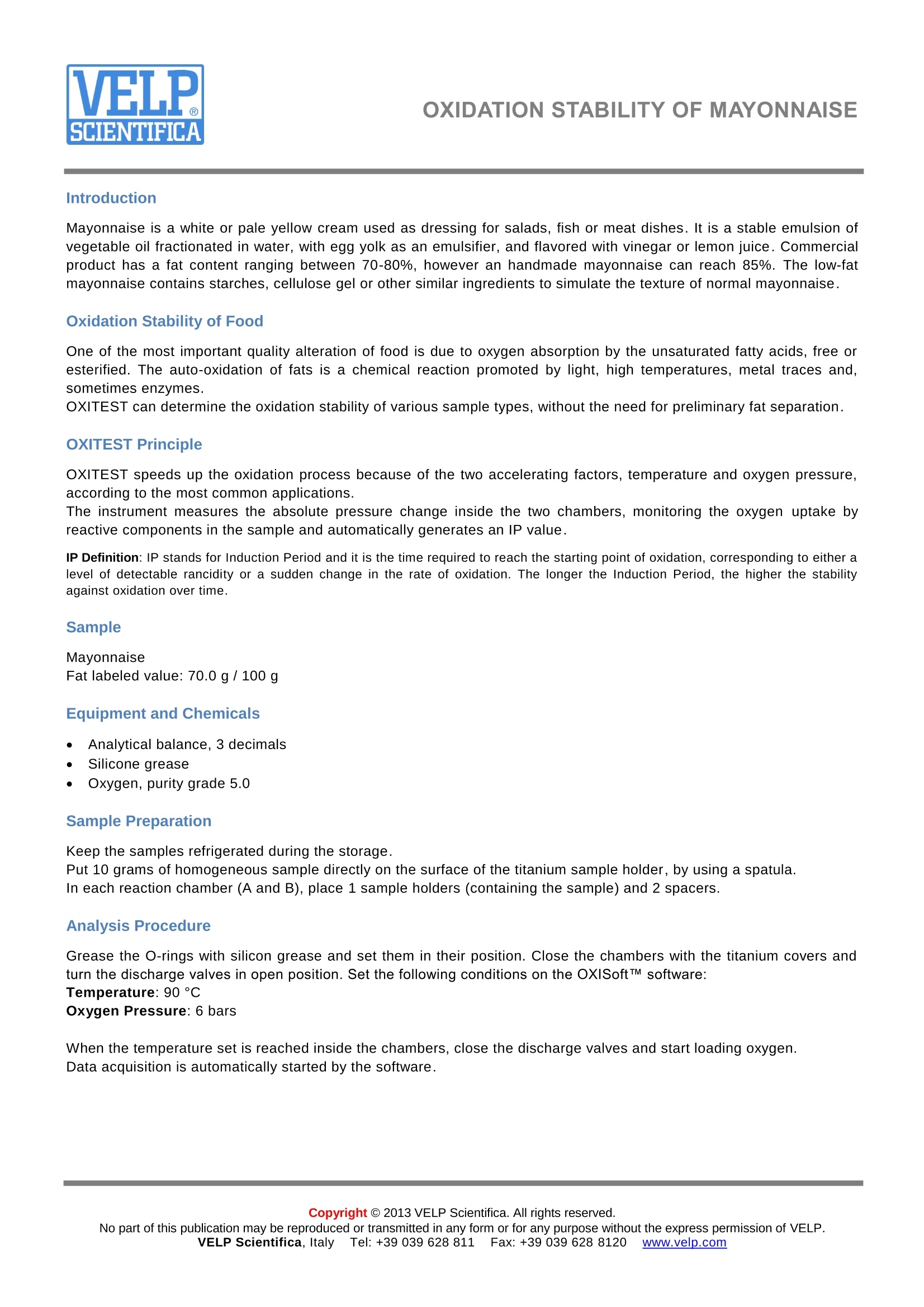

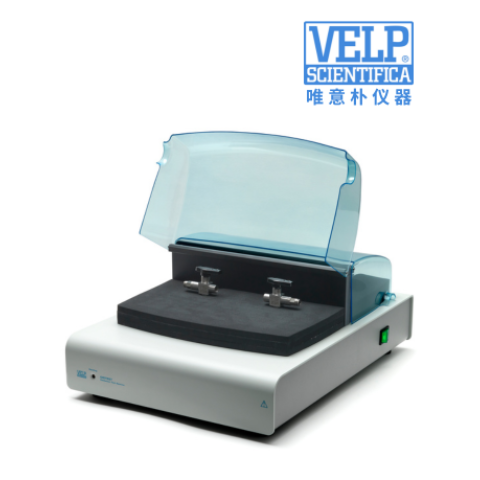

APPLICATION NOTEF&F-0-003-2014/A1 OXIDATION STABILITY OF MAYONNAISE Oxidation Stability of Mayonnaise Reference: International Standard Procedure AOCS Cd 12c-16 Tested with VELP Scientifica OXITEST Oxidation Stability Reactor (Code F30900248) Introduction Mayonnaise is a white or pale yellow cream used as dressing for salads, fish or meat dishes. It is a stable emulsion ofvegetable oil fractionated in water, with egg yolk as an emulsifier, and flavored with vinegar or lemon juice. Commercialproduct has a fat content ranging between 70-80%, however an handmade mayonnaise can reach 85%. The low-fatmayonnaise contains starches, cellulose gel or other similar ingredients to simulate the texture of normal mayonnaise. Oxidation Stability of Food One of the most important quality alteration of food is due to oxygen absorption by the unsaturated fatty acids, free oresterified. The auto-oxidation of fats is a chemical reaction promoted by light, high temperatures, metal traces and,sometimes enzymes. OXITEST can determine the oxidation stability of various sample types, without the need for preliminary fat separation. OXITEST Principle OXITEST speeds up the oxidation process because of the two accelerating factors, temperature and oxygen pressure,according to the most common applications. The instrument measures the absolute pressure change inside the two chambers, monitoring the oxygen uptake byreactive components in the sample and automatically generates an IP value. IP Definition: IP stands for Induction Period and it is the time required to reach the starting point of oxidation, corresponding to either alevel of detectable rancidity or a sudden change in the rate of oxidation. The longer the Induction Period, the higher the stabilityagainst oxidation over time. Sample Mayonnaise Fat labeled value: 70.0 g / 100 g Equipment and Chemicals Analytical balance, 3 decimals ● Silicone grease ●· Oxygen, purity grade 5.0 Sample Preparation Keep the samples refrigerated during the storage. Put 10 grams of homogeneous sample directly on the surface of the titanium sample holder, by using a spatula. In each reaction chamber (A and B), place 1 sample holders (containing the sample) and 2 spacers. Analysis Procedure Grease the O-rings with silicon grease and set them in their position. Close the chambers with the titanium covers andturn the discharge valves in open position. Set the following conditions on the OXISoft TM software: Temperature: 90°C Oxygen Pressure: 6 bars When the temperature set is reached inside the chambers, close the discharge valves and start loading oxygen.Data acquisition is automatically started by the software. Typical Results on Mayonnaise The sample has been monitored twice. At the end of the oxidation tests, the IP of every run is calculated by the software OXISoft M. Sample Weight (g) Set Point (bars) Set Point (°C) IP (hh:mm) Line Mayonnaise A 10 6,0 90,0 24:07 Mayonnaise A 10 6,0 90,0 23:56 6,5- 00:000 002:00 04:00 06:00 08:00 10:001 112:000014:00116:0018:00 20:0022:0024:00 26:00o 28:00 30:00 32:00 34:00 36:00 38:00 40:00) 42:00 44:00Time [hr:min] Conclusion OXITEST unit is able to investigate the oxidation stability of mayonnaise. The longer the Induction Period, the higher thestability against oxidation over time. Mayonnaise is an important ingredient in food industry and, knowing its stability,can help to choose it in making end product's formulation as base for many other chilled sauces and salad dressings. Benefits of OXITEST are: Test is made directly on the whole sample No need for preliminary fat separation of the sample ● Resistant titanium chamber Time saving analysis, if compared to the traditional methods Especially designed for R&D, Product Development and Quality Control labs Many investigations available through the software OXISoft TM: 1. Repeatability test: a series of tests run on the same sample or standard to verify its IP period, to calculateaccuracy and repeatability of the data 2. Freshness test: to verify the quality of different lots, for example of the same raw material, and compare them 3. Formula comparison: to identify the most stable formula of a finished product, under the same conditions 4. Packaging comparison: for testing which packaging maintains the product in the freshest condition 5. IP during ageing: to obtain a graph of the decrease of the product IP during the shelf-life period 6. Estimated shelf life: to have a prediction of oxidation stability during the shelf life. Copyright C VELP Scientifica. All rights reserved.No part of this publication may be reproduced or transmitted in any form or for any purpose without the express permission of VELP.VELP Scientifica, Italy Tel:+ Fax: + www.velp.com 蛋黄酱是一种白色或淡黄色的奶油,用于沙拉、鱼或肉类菜肴的调味料。它是植物油在水中分馏,以蛋黄为乳化剂,用醋或柠檬汁调味而成的稳定乳液。商业产品的脂肪含量在70-80%之间,而手工蛋黄酱的脂肪含量可达85%。低脂蛋黄酱含有淀粉、纤维素凝胶或其他类似成分,以模拟普通蛋黄酱的质地。蛋黄酱是食品工业的一种重要原料,了解其稳定性,可以帮助选择它作为许多其他冰鲜酱料和沙拉酱料的基础配方。实验样品:Mayonnaise Fat labeled value: 70.0 g / 100 g参考标准:国际标准程序AOCS Cd 12c-16实验仪器:意大利VELP OXITEST油脂氧化分析仪,可以测定各种类型样品的氧化稳定性,而不需要进行初步的脂肪分离。检测原理:根据最常见的应用,OXITEST会因为温度和氧压这两个加速因素而加速氧化过程。该仪器测量两个腔内的绝对压力变化,监测样品中活性成分的吸氧情况,并自动生成IP值。IP代表诱导期,是达到氧化起始点所需的时间,对应于可检测到的酸碱度水平或氧化速率的突然变化。诱导时间越长,抗氧化稳定性越高。检测结果:该样本已被监测两次。在氧化测试结束时,利用OXISoft TM软件计算每一次测试的IP。OXITEST单元可以研究蛋黄酱的氧化稳定性。诱导时间越长,抗氧化稳定性越高。

关闭-

1/3

-

2/3

还剩1页未读,是否继续阅读?

继续免费阅读全文产品配置单

北京盈盛恒泰科技有限责任公司为您提供《蛋黄酱中氧化稳定性检测方案(食用油品分析)》,该方案主要用于半固态复合调味料中理化分析检测,参考标准《暂无》,《蛋黄酱中氧化稳定性检测方案(食用油品分析)》用到的仪器有VELP-油脂氧化分析仪OXITEST、意大利VELP公司-食品油脂氧化分析仪。

我要纠错

推荐专场

相关方案

咨询

咨询