方案详情文

智能文字提取功能测试中

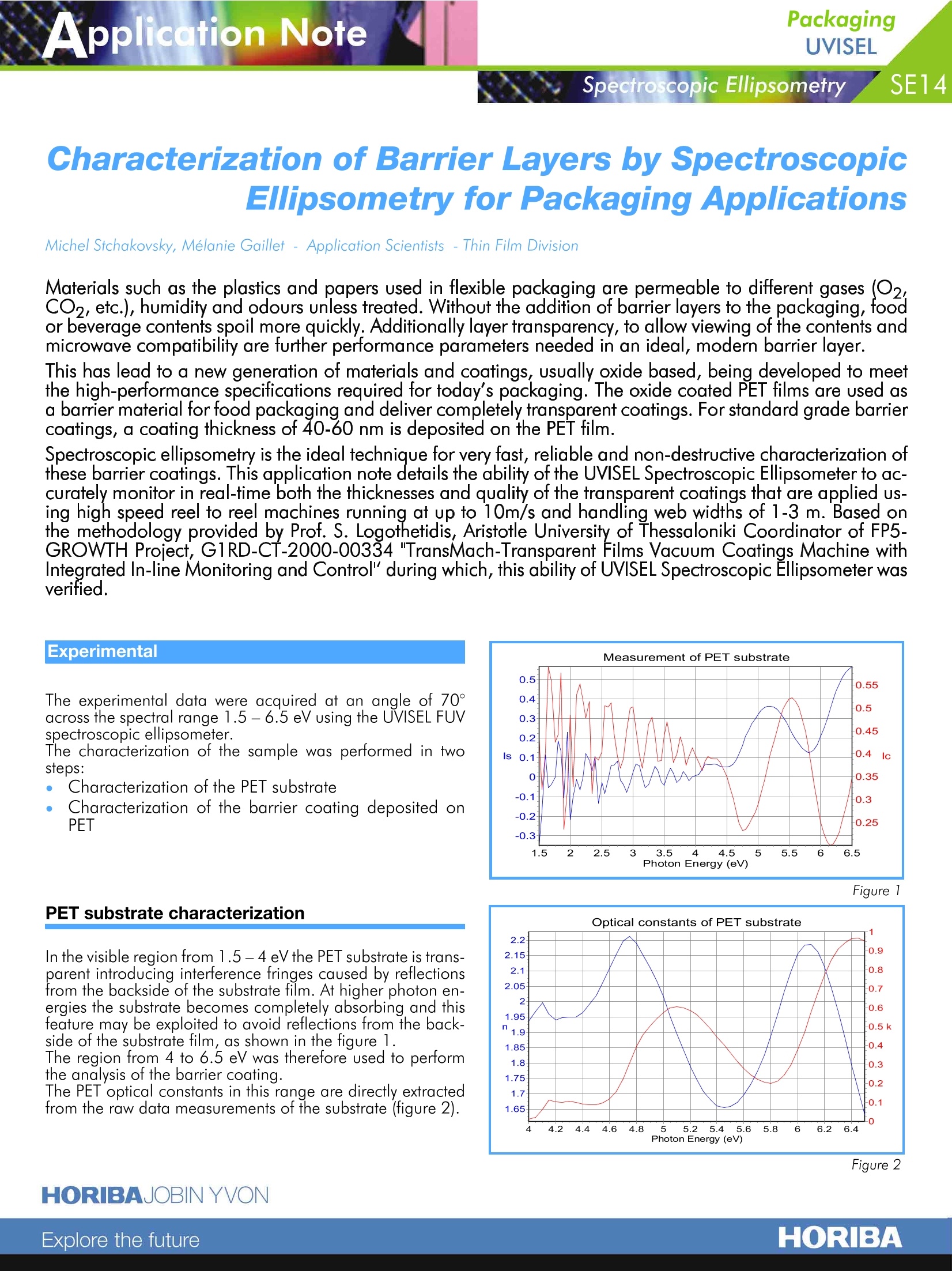

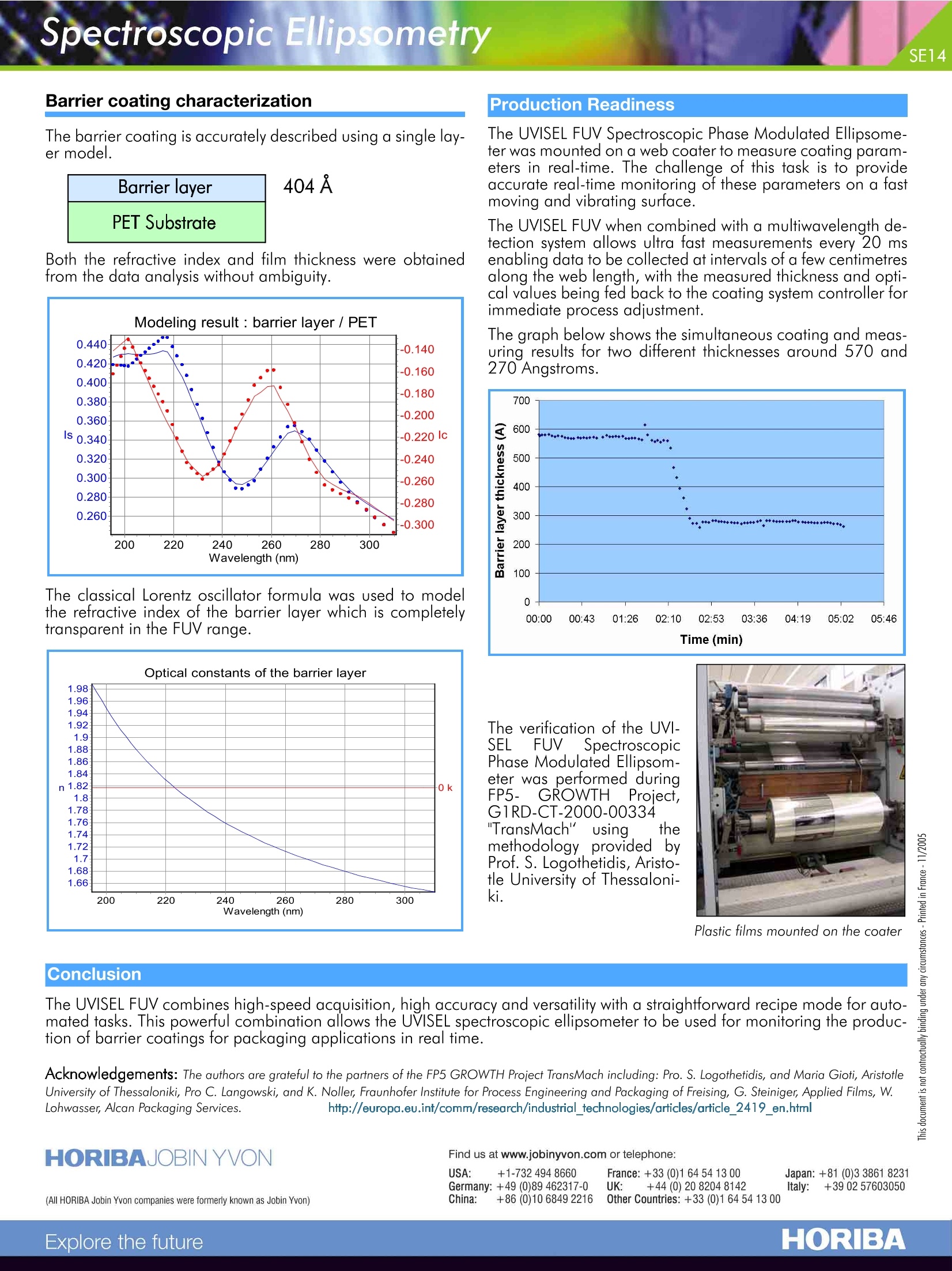

Application NotePackagingUVISELSpectroscopic EllipsometrySE14 Spectroscopic Ellipsometry Characterization of Barrier Layers by SpectroscopicplciEllipsometry for Packaging Applications Michel Stchakovsky, Melanie Gaillet - Application Scientists -Thin Film Division Materials such as the plastics and papers used in flexible packaging are permeable to different gases ((O,CO2, etc.),humidity and odours unless treated. Without the addition of barrier layers to the packaging, foodor beverage contents spoil more quickly. Additionally layer transparency, to allow viewing of the contents andmicrowave compatibility are further performance parameters needed in an ideal, modern barrier layer. This has lead to a new generation of materials and coatings, usually oxide based, being developed to meetthe high-performance specifications required for today's packaging. The oxide coated PET films are used asa barrier material for food packaging and deliver completely transparent coatings. For standard grade barriercoatings, a coating thickness of 40-60 nm is deposited on the PET film. Spectroscopic ellipsometry is the ideal technique for very fast, reliable and non-destructive characterization ofthesebarrier coatings. This application note details the ability of the UVISEL Spectroscopic Ellilipsometer to ac-curately monitor in real-time both the thicknesses and quality ot the transparent coatings that are appliedUS-ing high speed reel to reelmachines running at up to 10m/s and handling web widths of 1-3 m. Based onthe methodology provided by Prof. S. Logothetidis, Aristotle University of Thessaloniki Coordinator of FP5-GROWTH Project, G1RD-CT-2000-00334 "TransMach-Transparent Films Vacuum Coatings Machine withIntegrated In-line Monitoring and Control" during which, this ability of UVISEL Spectroscopic Ellipsometer wasverified. Experimental The experimental data were acquired at an angle of 70°across the spectral range 1.5-6.5 eV using the UVISEL FUVspectroscopic ellipsometer. The characterization of the sample was performed in twosteps: Characterization of the PET substrate Characterization of the barrier coating deposited onPET PET substrate characterization In the visible region from 1.5-4 eV the PET substrate is trans-parent introducing interference fringes caused by reflectionsfrom the backside of the substrate fifilrm. At higher photon en-ergies the substrate becomes completely absorbing and thisfeature may be exploited to avoid reflections from the back-side of the substrate film, as shown in the figure 1. The region from 4 to 6.5 eV was therefore used to performthe analysis of the barrier coating. The PET optical constants in this range are directly extractedfrom the raw data measurements of the substrate (figure 2). Figure I Barrier coating characterization The barrier coating is accurately described using a single lay-er model. 404A Both the refractive index and film thickness were obtainedfrom the data analysis without ambiguity. The classical Lorentz oscillator formula was used to modelthe refractive index of the barrier layer which is completelytransparent in the FUV range. The UVISEL FUV Spectroscopic Phase Modulated Ellipsome-ter was mounted on a web coater to measure coating param-eters in real-time. The challenge of this task is to provideaccurate real-time monitoring of these parameters on a fastmoving and vibrating surface. The UVISEL FUV when combined with a multiwavelength de-tection system allows ultra fast measurements every 20 msenabling data to be collected at intervals of a few centimetresalong the web length, with the measured thickness and opti-cal values being fed back to the coating system controller forimmediate process adjustment. The graph below shows the simultaneous coating and meas-uring results for two different thicknesses around 570 and270 Angstroms. The verification of the UVI-SEL FUV SpectroscopicPhase Modulated Ellipsom-eter was performed duringFP5- GROWTH Project,G1RD-CT-2000-00334"TransMach"using9. themethodology provided byProf. S. Logothetidis, Aristo-tle University of Thessaloni-ki. Plastic films mounted on the coater Conclusion The UVISEL FUV combines high-speed acquisition, high accuracy and versatility with a straightforward recipe mode for auto-mated tasks. This powerful combination allows the UVISEL spectroscopic ellipsometer to be used for monitoring the produc-tion of barrier coatings for packaging applications in real time. Acknowledgements: The authors are grateful to the partners of the FP5 GROWTH Project TransMach including: Pro. S. Logothetidis, and Maria Gioti, AristotleUniversity of Thessaloniki, Pro C. Langowski, and K. Noller, Fraunhofer Institute for Process Engineering and Packaging of Freising, G. Steiniger, Applied Films, W.Lohwasser, Alcan Packaging Services. http://europa.eu.int/comm/research/industrial_technologies/articles/article_2419_en.html HORIBAJOBIN YVON USA: +1-732 494 8660 France: +33 (0)164541300 Germany: +49(0)89462317-0 UK:+44 (0)20 8204 8142 ( J apan: +81 (0)3 38618231 Italy : +39 02 57603050 ) FigureHORIBA Find us at www.jobinyvon.com or telephone:(All HORIBA Jobin Yvon companies were formerly known as Jobin Yvon)HORIBAExplore the future The UVISEL FUV combines high-speed acquisition, high accuracy and versatility with a straightforward recipe mode for automated tasks. This powerful combination allows the UVISEL spectroscopic ellipsometer to be used for monitoring the production of barrier coatings for packaging applications in real time.

关闭-

1/2

-

2/2

产品配置单

HORIBA(中国)为您提供《封装应用中的势垒层中过程控制检测方案(椭偏仪)》,该方案主要用于其他中过程控制检测,参考标准《暂无》,《封装应用中的势垒层中过程控制检测方案(椭偏仪)》用到的仪器有HORIBA UVISEL Plus研究级经典型椭偏仪 。

我要纠错

相关方案

咨询

咨询