方案详情文

智能文字提取功能测试中

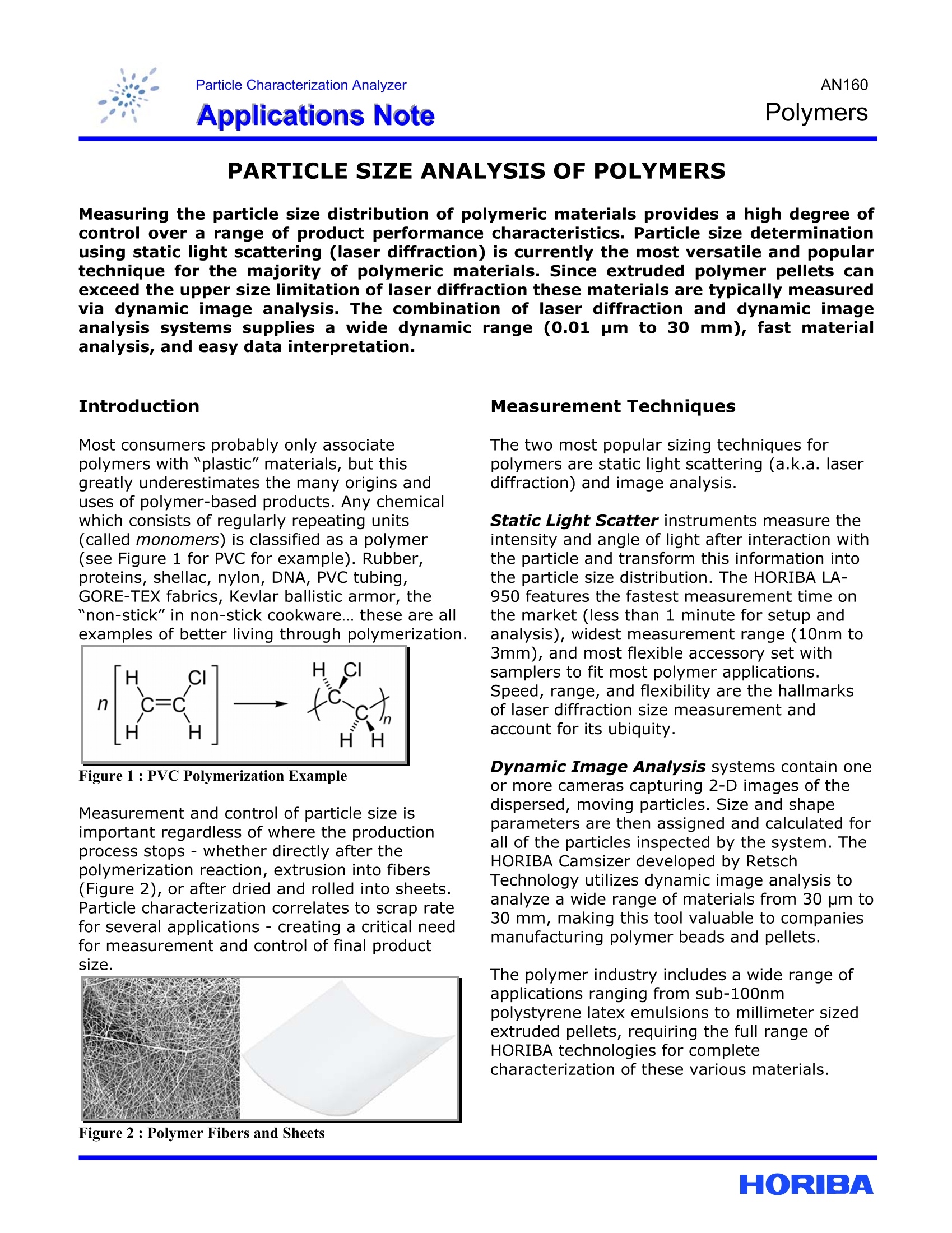

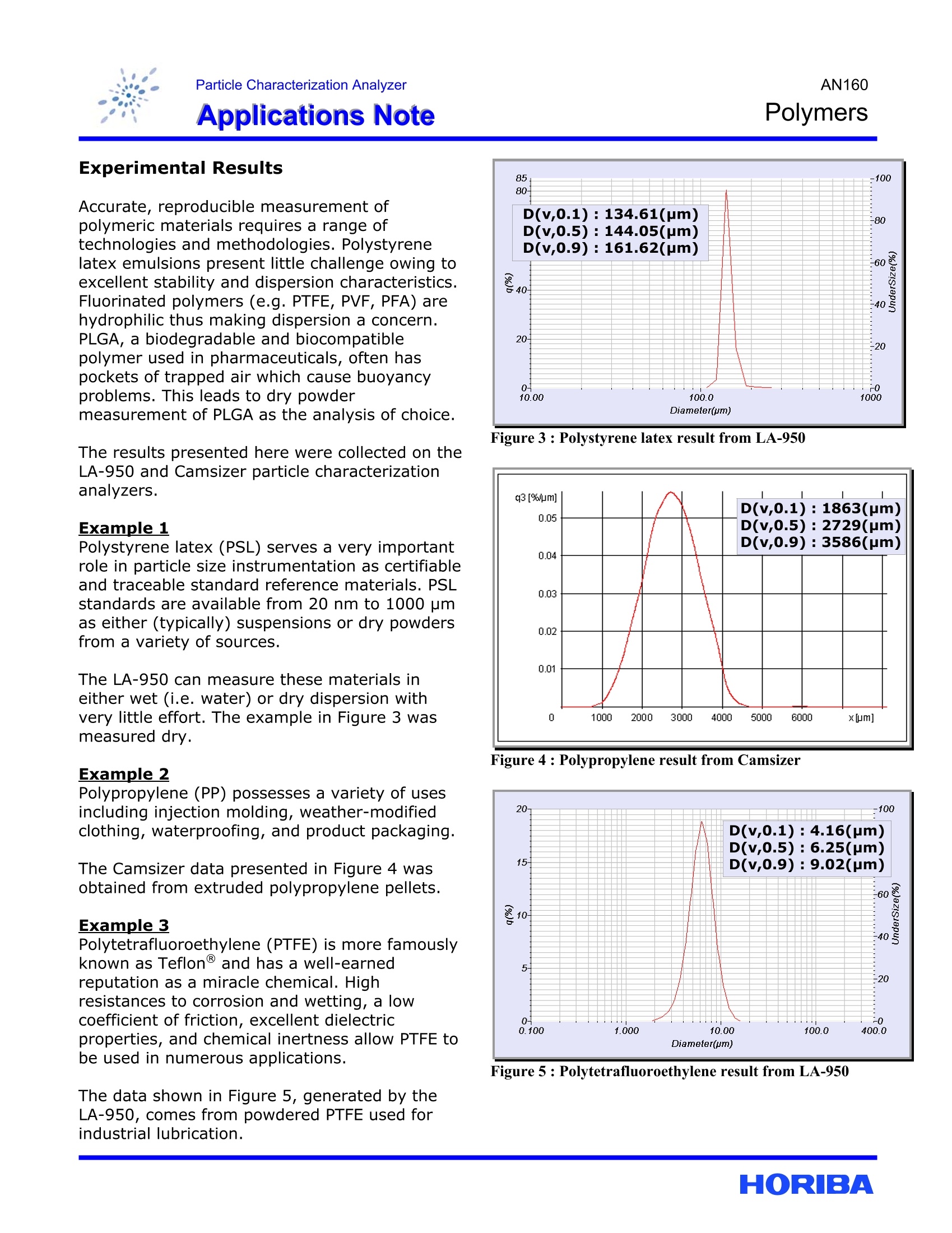

AN160Particle Characterization AnalyzerApplications NotePolymers PARTICLE SIZE ANALYSIS OFPOLYMERS Measuring the particle size distribution of polymeric materials provides a high degree ofcontrol over a range of product performance characteristics. Particle size determinationusing static light scattering (laser diffraction) is currently the most versatile and populartechnique for the majority of polymeric materials. Since extruded polymer pellets canexceed the upper size limitation of laser diffraction these materials are typically measuredvia dynamic image analysis. The combination of laser diffraction and dynamic imageanalysis systems supplies a wide dynamic range (0.01 pm to 30 mm), fast materialanalysis, and easy data interpretation. Most consumers probably only associatepolymers with "plastic" materials, but thisgreatly underestimates the many origins anduses of polymer-based produ, rcatnsa.a tiAnny chemicalwhich consists of regularly repeating units(called monomers) is classified as a polymer(see Figure 1 for PVC for example). Rubber,PYGproteins,shellac, nylon, DNA, PVC tubing,GORE-TEX fabrics, Kevlar ballistic armor, thenon-stick”in non-stick cookware...these are allexamples of better living through polymerization. Figure 1 : PVC Polymerization Example Measurement and control of particle size isimportant regardless of where the productionprocessstops -whether directly after thepolymerization reaction, extrusion into fibers(Figure 2), or after dried and rolled into sheets.Particle characterization correlates to scrap ratefor several applications - creating a critical needfor measurement and control of final productsize. The two most popular sizing techniques forpolymers are static light scattering (a.k.a. laserdiffraction) and image analysis. Static Light Scatter instruments measure theintensity and angle of light after interaction withthe particle and transform this information intothe particle size distribution. The HORIBA LA-950 features the fastest measurement time onthe market (less than 1 minute for setup andanalysis), widest measurement range (10nm to3mm), and most flexible accessory set withsamplers to fit most polymer applications.Speed, range, and flexibility are the hallmarksof laser diffraction size measurement andaccount for its ubiquity. Dynamic Image Analysis systems contain oneor more cameras capturing 2-D images of thedispersed, moving particles. Size and shapeparameters are then assigned and calculated forall of the particles inspected by the system. TheHORIBA Camsizer developed by RetschTechnology utilizes dynamic image analysis toanalyze a wide range of materials from 30 pm to30 mm, making this tool valuable to companiesmanufacturing polymer beads and pellets. The polymer industry includes a wide range ofapplications ranging from sub-100nmpolystyrene latex emulsions to millimeter sizedextruded pellets, requiring the full range ofHORIBA technologies for completecharacterization of these various materials. Experimental Results Accurate, reproducible measurement ofpolymeric materials requires a range oftechnologies and methodologies. Polystyrenelatex emulsions present little challenge owing toexcellent stability and dispersion characteristics.Fluorinated polymers (e.g. PTFE, PVF, PFA) arehydrophilic thus making dispersion a concern.PLGA, a biodegradable and biocompatiblepolymer used in pharmaceuticals, often haspockets of trapped air which cause buoyancyproblems. This leads to dry powdermeasurement of PLGA as the analysis of choice. The results presented here were collected on theLA-950 and Camsizer particle characterizationanalyzers. Example 1 Polystyrene latex (PSL) serves a very importantrole in particle size instrumentation as certifiableand traceable standard reference materials. PSLstandards are available from 20 nm to 1000 pmas either (typically) suspensions or dry powdersfrom a variety of sources. The LA-950 can measure these materials ineither wet (i.e. water) or dry dispersion withvery little effort. The example in Figure 3 wasmeasured dry. Example 2 Polypropylene (PP) possesses a variety of usesincluding injection molding, weather-modifiedclothing, waterproofing, and product packaging. The Camsizer data presented in Figure 4 wasobtained from extruded polypropylene pellets. Example 3 Polytetrafluoroethylene (PTFE) is more famouslyknown as Teflon@ and has a well-earnedreputation as a miracle chemical. Highresistances to corrosion and wetting, a lowcoefficient of friction, excellent dielectricproperties, and chemical inertness allow PTFE tobe used in numerous applications. The data shown in Figure 5, generated by theLA-950, comes from powdered PTFE used forindustrial lubrication. Figure 3: Polystyrene latex result from LA-950 Figure 4:Polypropylene result from Camsizer Figure 5 : Polytetrafluoroethylene result from LA-950 Example 4 Polyvinyl chloride (IUPAC Polychloroethene),abbreviated PVC is another classic example of apolymer performing many jobs. PVC is featuredin construction the world over because of its lowcost, ease of use, and durability. Other uses ofPVC include pipes, electric wire insulation,magnetic stripe cards, vinyl siding, and conduitfixtures. Figure 6 is an example of PVC flakes measuredon the Camsizer. As the needs of the chemical industry change and products require more detailed inspection tomaximize quality and quantity,the analytical instrumentation available must adapt to fill the space.Both the LA-950 and Camsizer successfully meet the needs for research and routine quality controlthrough the provision of speed, ease of use, repeatability, reproducibility, and reliability. Laserdiffraction analyzers measure from nanometer to millimeter sized wet or dry dispersed polymers.Dynamic image analysis systems are preferred when product size grows and shape factors becomeimportant. Copyright 2008, HORIBA Instruments, Inc. For further information on this document or our products, please contact:HORIBA Instruments, Inc.17671 Armstrong Ave.Irvine, CA 92614 USA(949) 250-4811 www.horibalab.com HORIBA As the needs of the chemical industry change and products require more detailed inspection to maximize quality and quantity, the analytical instrumentation available must adapt to fill the space. Both the LA-950 and Camsizer successfully meet the needs for research and routine quality control through the provision of speed, ease of use, repeatability, reproducibility, and reliability. Laser diffraction analyzers measure from nanometer to millimeter sized wet or dry dispersed polymers. Dynamic image analysis systems are preferred when product size grows and shape factors become important.

关闭-

1/3

-

2/3

还剩1页未读,是否继续阅读?

继续免费阅读全文产品配置单

HORIBA(中国)为您提供《PSL,PP,PTFE,IUPAC中粒度分析检测方案(激光粒度仪)》,该方案主要用于其他中粒度分析检测,参考标准《暂无》,《PSL,PP,PTFE,IUPAC中粒度分析检测方案(激光粒度仪)》用到的仪器有Partica mini LA-350-紧凑型激光粒度仪。

我要纠错

相关方案

咨询

咨询