方案详情文

智能文字提取功能测试中

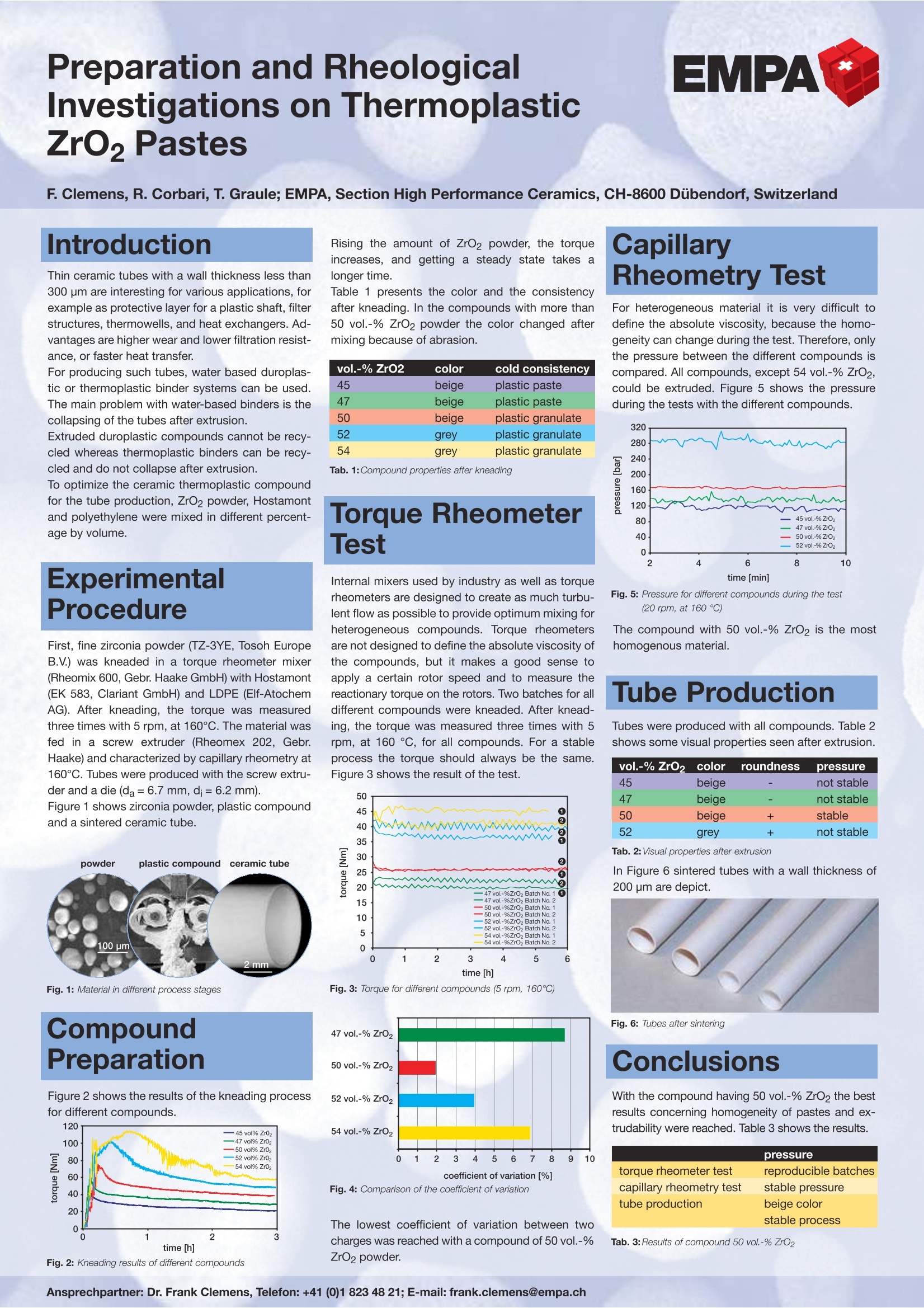

Ansprechpartner: Dr. Frank Clemens, Telefon: +41 (0)1 823 48 21;E-mail: frank.clemens@empa.ch Preparation and RheologicalInvestigations on ThermoplasticZrO2 Pastes F. Clemens, R. Corbari, T. Graule; EMPA, Section High Performance Ceramics,CH-8600 Dubendorf, Switzerland Introduction Thin ceramic tubes with a wall thickness less than300 um are interesting for various applications, forexample as protective layer for a plastic shaft, filterstructures, thermowells, and heat exchangers. Ad-vantages are higher wear and lower filtration resist-ance, or faster heat transfer. For producing such tubes, water based duroplas-tic or thermoplastic binder systems can be used.The main problem with water-based binders is thecollapsing of the tubes after extrusion. Extruded duroplastic compounds cannot be recy-cled whereas thermoplastic binders can be recy-cled and do not collapse after extrusion. To optimize the ceramic thermoplastic compoundfor the tube production, ZrO2 powder, Hostamontand polyethylene were mixed in different percent-age by volume. ExperimentalProcedure First, fine zirconia powder (TZ-3YE, Tosoh EuropeB.V.) was kneaded in a torque rheometer mixer(Rheomix 600, Gebr. Haake GmbH) with Hostamont(EK 583, Clariant GmbH) and LDPE (Elf-AtochemAG). After kneading, the torque was measuredthree times with 5 rpm, at 160℃. The material wasfed in a screw extruder (Rheomex 202, Gebr.Haake) and characterized by capillary rheometry at160°C. Tubes were produced with the screw extru-der and a die (da =6.7 mm,dj=6.2mm). Figure 1 shows zirconia powder, plastic compoundand a sintered ceramic tube. Fig. 1: Material in different process stages CompoundPreparation Figure 2 shows the results of the kneading processfor different compounds. Rising the amount of ZrO2 powder, the torqueincreases, and getting a steady state takes alonger time. Table 1 presents the color and the consistencyafter kneading. In the compounds with more than50 vol.-% ZrO2 powder the color changed aftermixing because of abrasion. vol.-%ZrO2 color cold consistency 45 beige plastic paste 47 beige plastic paste 50 beige plastic granulate 52 grey plastic granulate 54 grey plastic granulate Tab. 1:Compound properties after kneading Torque RheometerTest Internal mixers used by industry as well as torquerheometers are designed to create as much turbu-lent flow as possible to provide optimum mixing forheterogeneous compounds. Torque rheometersare not designed to define the absolute viscosity ofthe compounds, but it makes a good sense toapply a certain rotor speed and to measure thereactionary torque on the rotors. Two batches for alldifferent compounds were kneaded. After knead-ing, the torque was measured three times with 5rpm, at 160 C, for all compounds. For a stableprocess the torque should always be the same.Figure 3 shows the result of the test. Fig. 3: Torque for different compounds (5 rpm, 160℃) Fig. 4: Comparison of the coefficient of variation The lowest coefficient of variation between twocharges was reached with a compound of 50 vol.-%ZrO2 powder. CapillaryRheometry Test For heterogeneous material it is very difficult todefine the absolute viscosity, because the homo-geneity can change during the test. Therefore, onlythe pressure between the different compounds iscompared. All compounds, except 54 vol.-% ZrO2,could be extruded. Figure 5 shows the pressureduring the tests with the different compounds. Fig. 5: Pressure for different compounds during the test(20 rpm,at 160 ℃) The compound with 50 vol.-% ZrO2 is the mosthomogenous material. Tube Production Tubes were produced with all compounds. Table 2shows some visual properties seen after extrusion. vol.-%Zro2 roundness Tab. 2: Visual properties after extrusion In Figure 6 sintered tubes with a wall thickness of200 pm are depict. Fig.6: Tubes after sintering Conclusions With the compound having 50 vol.-% ZrO2 the bestresults concerning homogeneity of pastes and ex-trudability were reached. Table 3 shows the results. pressure torque rheometer testcapillary rheometry testtube production reproducible batches stable pressure beige color stable process Tab. 3: Results of compound 50 vol.-% ZrO2

关闭-

1/1

产品配置单

赛默飞世尔科技材料表征为您提供《热塑性塑料中流变性能检测方案(流变仪)》,该方案主要用于其他中流变性能检测,参考标准《暂无》,《热塑性塑料中流变性能检测方案(流变仪)》用到的仪器有多功能转矩流变仪HAAKE PolyLab OS。

我要纠错

相关方案

咨询

咨询