方案详情文

智能文字提取功能测试中

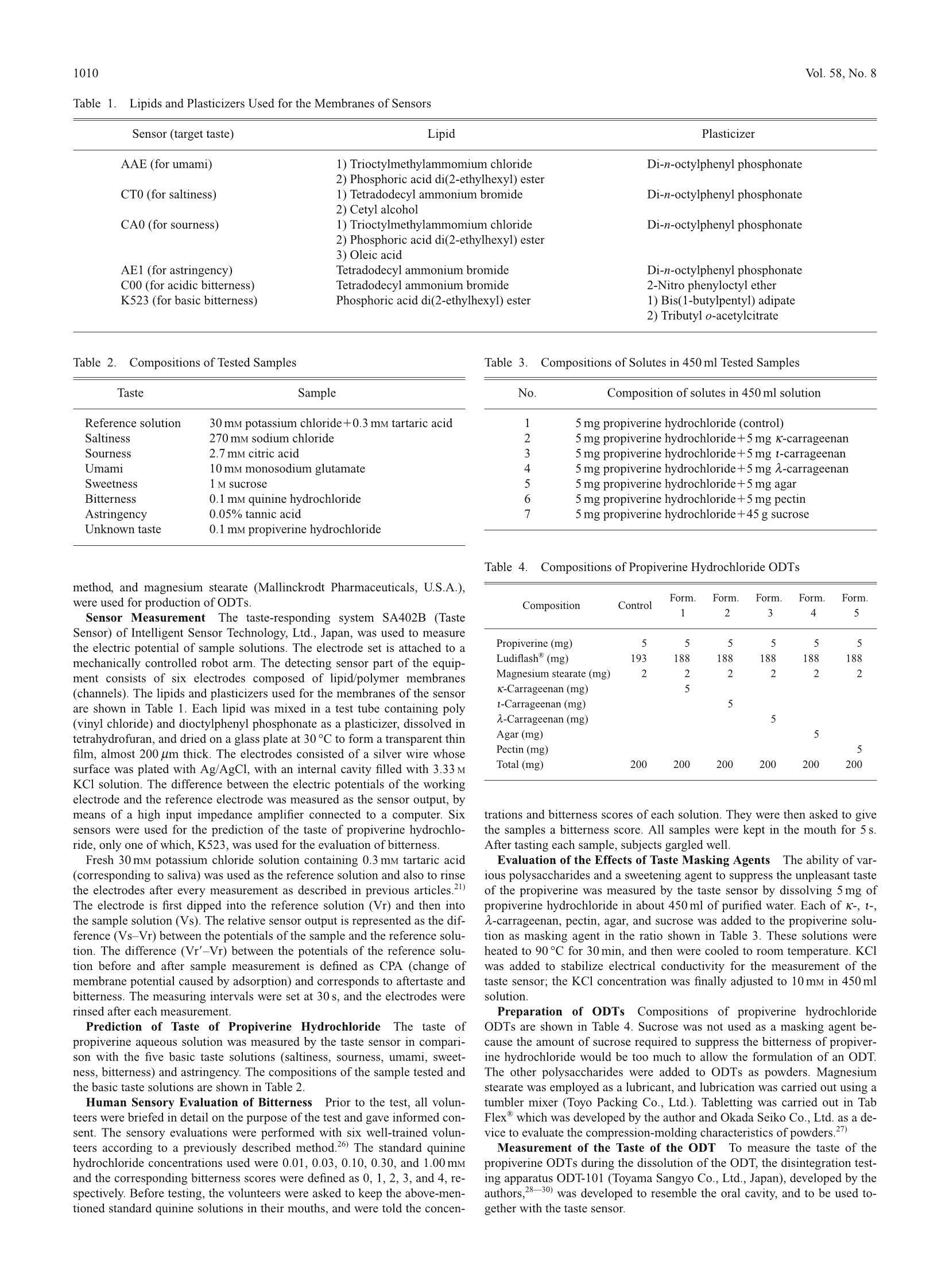

1009Chem. Pharm. Bull.58(8) 1009—1014 (2010)August 2010Regular Article 1010Vol. 58, No. 8 * To whom correspondence should be addressed. e-mail: t-harada@hhc.eisai.co.jpC 2010 Pharmaceutical Society of Japan A New Method for Evaluating the Bitterness of Medicines in DevelopmentUsing a Taste Sensor and a Disintegration Testing Apparatus Tsutomu HARADA,*.4 Takahiro UcHIDA,’Miyako YoSHIDA,’ Yoshikazu KoBAYASHI,Ryuichi NARAZAKI, and Takayuki OHWAKI° “Planning & Operations Section, Customer Joy Department, CEO office, Eisai Co., Ltd.; 5-5-5 Koishikawa, Bunkyo-ku,Tokyo 112-8088, Japan: School of Pharmaceutical Sciences, Mukogawa Women’s University; 11-68 Koshien 9-Bancho,Nishinomiya, Hyogo 663-8197, Japan: ‘Intelligent Sensor Technology, Inc.; 5-1-1 Onna, Atsugi, Kanagawa 243-0032,Japan: Formulation Research, CMC Japan, Pharmaceutical Science and Technology CFU, Eisai Co., Ltd.; and DrugDevelopment Technology Center, Customer Joy Department, CEO Office, Eisai Co., Ltd.;1 Kawashimatakehaya-machi,Kakamigahara, Gifu 501-6195, Japan. Received December 11, 2009; accepted May 14, 2010; published online May 28, 2010 The purpose of this study was to demonstrate the usefulness and wide applicability of a taste sensor and anew disintegration testing apparatus in the development and/or evaluation of orally disintegrating tablets(ODTs). In this paper, we described methods for the effective utilization of a taste sensor in the development of anew medicine. First we predicted the taste of propiverine hydrochloride, a model drug substance whose taste isunknown, using a taste sensor. Then we screened masking agents for their ability to suppress the bitterness ofpropiverine hydrochloride, and manufactured ODTs of propiverine hydrochloride with various masking agents.The tastes of these ODTs were then evaluated in chronological order by combining the taste sensor with the newdisintegration testing apparatus, ODT-101, to resemble the oral cavity. As a result, we were able to evaluate thetaste of propiverine hydrochloride and the effectiveness of various masking agents in ODTs. The result using thiscombination of taste sensor and ODT-101 shows good agreement with the results of human gustatory sensationtesting, thus demonstrating the usefulness and applicability of the taste sensor and disintegration testing appara-tus, ODT-101, in the development of new medicine. Key words taste sensor; disintegration testing apparatus; propiverine hydrochloride; orally disintegrating tablet; taste maskingagent; bitterness suppression The purpose of this study was to demonstrate the useful-ness and wide applicability of a taste sensor and a new disin-tegration testing apparatus in the development of new drugproducts. In recent years, orally disintegrating tablets, whichare easy for children or elderly people to take, have becomeincreasingly important in improving compliance. In the caseof drug substances with unpleasant tastes, the evaluation oftaste of the drug and the technology of taste masking seemsto be so important in formulation design. At the same time,intense international competition in thefield of drug development has created a vital need for im-provements in the efficiency of drug development methods.The early design of a simplified formulation, prior to the de-velopment of a final commercial product, has become an im-portant strategy in the early drug development process, toallow clinical trials to start earlier and permit screening ofnew molecular entities. A simple solution or suspension of adrug substance is often the first choice for early testing, asthis will have the highest bioavailability and produce thehighest bodily exposure. The new chemical entity cannot betasted, however, for safety reasons, so researchers must inves-tigate its taste in other ways in order to allow a single-blindtrial using the active material and a placebo. There have been various studies on the quantitative evalua-tion of taste of medicines using a taste sensor.-9 Most pre-vious experimental studies using the taste sensor have in-volved the quantitative evaluation of medicines with knowntastes or bitterness suppression of a known product.0-24)However, no research has yet been carried out to predict thetaste of an unknown medicine. Taste sensors can measureonly liquid samples. Therefore, researchers can only measuretaste after dissolving solid or semi-solid samples in medium. In the case of an orally disintegrating tablet (ODT), however,taste is evaluated in the process of dissolving the ODT in thesaliva of the oral cavity, leaving a possibility that the meas-urement of the taste of an ODT solution is different from themeasurement of taste during the process of ODT disintegra-tion in the oral cavity. In this paper, therefore, we describe methods for the effec-tive utilization of a taste sensor and a new disintegration test-ing apparatus in the development of a new medicine. First wepredicted the taste of propiverine hydrochloride, a modeldrug substance whose taste is unknown, using a taste sensor.Then we screened masking agents for their ability to sup-press the unpleasant taste of propiverine hydrochloride, andmanufactured ODTs of propiverine hydrochloride with vari-ous masking agents. The tastes of these ODTs were thenevaluated in chronological order by combining the taste sen-sor with the new disintegration testing apparatus, ODT-101,to resemble the oral cavity. Experimental MaterialsPPropiverine hydrochloride powder was purchased fromt fimhApogepha Arzneimittel GmbH (Dresden, Germany). Basic taste standardswere prepared by Intelligent Sensor Technology, Inc. (Kanagawa, Japan).Quinine hydrochloride, ticlopidine hydrochloride and sucrose were pur-chased from Wako Pure Chemical Industries, Ltd. (Osaka, Japan). Eperizonehydrochloride, donepezil hydrochloride and azelastine hydrochloride weremanufactured by Eisai Co., Ltd. (Tokyo, Japan); K-, l-, and A-carrageenanand agar were gifts from Ina Food Industry Co., Ltd. (Nagano, Japan). Thecarrageenans are a polysaccharide family built up from subunits consistingof two galactose rings that carry an electric charge of up to three unitcharges derived from dissociated sulfate groups. The ideal structures indi-cate that the K-, l-, and A-carrageenans should be characterized by one, two,or three charge units, respectively, per subgroup.2) LM pectin was pur-chased from Sansho Co., Ltd. (Osaka, Japan); Ludiflash, a granulated prod-uct developed by BASF for production of ODTs by the direct tabletting AAE (for umami) 1) Trioctylmethylammomium chloride 2) Phosphoric acid di(2-ethylhexyl) ester Di-n-octylphenyl phosphonate CTO (for saltiness) 1) Tetradodecyl ammonium bromide Di-n-octylphenyl phosphonate 2) Cetyl alcohol CA0 (for sourness) 1) Trioctylmethylammomium chloride 2) Phosphoric acid di(2-ethylhexyl) ester Di-n-octylphenyl phosphonate 3) Oleic acid AE1 (for astringency) Tetradodecyl ammonium bromide Di-n-octylphenyl phosphonate C00 (for acidic bitterness) Tetradodecyl ammonium bromide 2-Nitro phenyloctyl ether K523 (for basic bitterness) Phosphoric acid di(2-ethylhexyl)ester 1) Bis(1-butylpentyl) adipate 2) Tributyl o-acetylcitrate Table 2. Compositions of Tested Samples Table 3. Compositions of Solutes in 450 ml Tested Samples method, and magnesium stearate (Mallinckrodt Pharmaceuticals, U.S.A.),were used for production of ODTs. Sensor Measurement The taste-responding system SA402B (TasteSensor) of Intelligent Sensor Technology, Ltd., Japan, was used to measurethe electric potential of sample solutions. The electrode set is attached to amechanically controlled robot arm. The detecting sensor part of the equip-ment consists of six electrodes composed of lipid/polymer membranes(channels). The lipids and plasticizers used for the membranes of the sensorare shown in Table 1. Each lipid was mixed in a test tube containing poly(vinyl chloride) and dioctylphenyl phosphonate as a plasticizer, dissolved intetrahydrofuran, and dried on a glass plate at 30°C to form a transparent thinfilm, almost 200 um thick. The electrodes consisted of a silver wire whosesurface was plated with Ag/AgCl, with an internal cavity filled with 3.33 MKCl solution. The difference between the electric potentials of the workingelectrode and the reference electrode was measured as the sensor output, bymeans of a high input impedance amplifier connected to a computer. Sixsensors were used for the prediction of the taste of propiverine hydrochlo-ride, only one of which, K523, was used for the evaluation of bitterness. Fresh 30mM potassium chloride solution containing 0.3 mM tartaric acid(corresponding to saliva) was used as the reference solution and also to rinsethe electrodes after every measurement as described in previous articles.2)The electrode is first dipped into the reference solution (Vr) and then intothe sample solution (Vs). The relative sensor output is represented as the dif-ference (Vs-Vr) between the potentials of the sample and the reference solu-tion. The difference (Vr'-Vr) between the potentials of the reference solu-tion before and after sample measurement is defined as CPA (change ofmembrane potential caused by adsorption) and corresponds to aftertaste andbitterness. The measuring intervals were set at 30 s, and the electrodes wererinsed after each measurement. Prediction of Taste of Propiverine Hydrochloride The taste ofpropiverine aqueous solution was measured by the taste sensor in compari-son with the five basic taste solutions (saltiness, sourness, umami, sweet-ness, bitterness) and astringency. The compositions of the sample tested andthe basic taste solutions are shown in Table 2. Human Sensory Evaluation of BitternessSPrior to the test, all volun-teers were briefed in detail on the purpose of the test and gave informed con-sent. The sensory evaluations were performed with six well-trained volun-teers according to a previously described method.26) The standard quininehydrochloride concentrations used were 0.01, 0.03, 0.10, 0.30, and 1.00 mMand the corresponding bitterness scores were defined as 0, 1, 2,3, and 4, re-spectively. Before testing, the volunteers were asked to keep the above-men-tioned standard quinine solutions in their mouths, and were told the concen- Taste Sample Reference solution 30 mM potassium chloride+0.3 mM tartaric acid Saltiness 270 mM sodium chloride Sourness 2.7 mM citric acid Umami 10 mM monosodium glutamate Sweetness 1 M sucrose Bitterness 0.1 mM quinine hydrochloride Astringency 0.05% tannic acid Unknown taste 0.1 mM propiverine hydrochloride Table 4. Compositions of Propiverine Hydrochloride ODTs Composition Form. Form. Form. Form. Form. Control 1 2 3 4 5 Propiverine(mg) 5 5 5 5 5 5 Ludiflash(mg) 193 188 188 188 188 188 Magnesium stearate (mg) 2 2 2 2 2 K-Carrageenan (mg) 5 t-Carrageenan (mg) 5 a-Carrageenan (mg) 5 Agar (mg) Pectin (mg) Total (mg) 5 5 200 200 200 200 200 200 trations and bitterness scores of each solution. They were then asked to givethe samples a bitterness score. All samples were kept in the mouth for 5 s.After tasting each sample, subjects gargled well. Evaluation of the Effects of Taste Masking Agents The ability of var-ious polysaccharides and a sweetening agent to suppress the unpleasant tasteof the propiverine was measured by the taste sensor by dissolving 5 mg ofpropiverine hydrochloride in about 450 ml of purified water. Each of K-, l-,a-carrageenan, pectin, agar, and sucrose was added to the propiverine solu-tion as masking agent in the ratio shown in Table 3. These solutions wereheated to 90°C for 30 min, and then were cooled to room temperature. KClwas added to stabilize electrical conductivity for the measurement of thetaste sensor; the KCl concentration was finally adjusted to 10 mM in 450 mlsolution. Preparation of ODTsSCompositions of propiverine hydrochlorideODTs are shown in Table 4. Sucrose was not used as a masking agent be-cause the amount of sucrose required to suppress the bitterness of propiver-ine hydrochloride would be too much to allow the formulation of an ODT.The other polysaccharides were added to ODTs as powders. Magnesiumstearate was employed as a lubricant, and lubrication was carried out using atumbler mixer (Toyo Packing Co., Ltd.). Tabletting was carried out in TabFlexwhich was developed by the author and Okada Seiko Co., Ltd. as a de-vice to evaluate the compression-molding characteristics of powders. Measurement of the Taste of the ODT To measure the taste of thepropiverine ODTs during the dissolution of the ODT, the disintegration test-ing apparatus ODT-101 (Toyama Sangyo Co., Ltd., Japan), developed by theauthors,28-30) was developed to resemble the oral cavity, and to be used to-gether with the taste sensor. Figure 1 is an illustration of the core structure of the ODT-101. An ODTsample is placed on a stainless-steel porous plate. Weight (2) is provided tothe shaft (1) which is capable of moving in the vertical direction and rotat-ing. The liquid surface of the test medium (450 ml purified water) is auto-matically adjusted by a pump so that the water level is slightly below thelower face of the porous plate. The liquid temperature is set to 37°C. In thisstudy, a 10-g weight was attached to a shaft and the shaft rotation rate wasset at 25 rpm. When the measurement start button is pressed, the shaft goesdown. The ODT is sandwiched between the rotating weight and the porousplate such that the load and shear force can be applied to the ODT. Simulta-neously, the block (3) is immersed in the test medium and the water level ofthe test medium increases, such that the lower face of the ODT is in contactwith the test medium. The ODT then absorbs the test medium by capillarysuction, resulting in disintegration. The effects of load, shear, and wetting,reproduce the conditions in the oral cavity in which an ODT becomes wetwith saliva and is lightly ground between the tongue and the roof of themouth. We measured the test medium 15 s after starting disintegration of an ODTand after full disintegration. In the 15-s test, ODT-101 was stopped and theODT removed from the test medium. Subsequently the test medium was fil-tered through mesh (No. 325) to produce the 15-s sample. In the same way,ODT-101 testing was stopped immediately after full disintegration of theODT, and the test medium filtered to produce the fully-disintegrated ODT Fig. 1. IIlustration of the Core Structure of a New Disintegration TestingApparatus ODT-101 sample. Sensory Evaluation of the Taste of ODT The human gustatory sensa-tion tests were performed with six well-trained volunteers. Prior to the test,all volunteers were given a detailed briefing on the purpose of the test andgave informed consent. They were asked to rinse their mouths out withwater. The control ODT of propiverine was used as a standard. At first, vol-unteers allowed the control ODT to disintegrate in their mouths and awardedit a bitterness score of5. Then a sample was placed on the tongue and theywere allowed to move the ODT with their tongues in the mouth. The swal-lowing of saliva was prohibited during the test. Immediately after the lastnoticeable granule or fragment had disintegrated, the volunteers rated thesample on an ascending bitterness scale of 0 to 5. After testing each sample,the volunteers gargled well. Results and Discussion Prediction of the Taste of Propiverine HydrochlorideFirst, the effect of propiverine aqueous solution on the re-sponses of six sensors comprising different lipid membraneswere compared with the six basic taste substances listed inTable 2. Figure 2 shows the sensor responses. The error barsrepresent standard deviations. Each sensor, except the umamitaste sensor AAE and the acid taste sensor CAO, respondedspecifically to each basic taste substance, making it possiblefor the taste sensor to correctly identify each taste. SensorK523 responds selectively to only a bitter taste.24) Propiver-ine solution therefore seems to a have bitter taste, as K523responded as much to the propiverine solution as the quininesolution. Principle component analysis was applied to thedata, as the responses of the umami taste sensor AAE and theacid taste sensor CAO look similar. The results are shown inFig. 3, which shows that principal component 1 (PC1) indi-cates astringency, because the plotted position of the tannicacid is farthest from the reference solution point. Similarly,PC2 indicates umami taste, PC3 indicates salty taste, andPC4 indicates bitter taste. Figure 3a shows that the umamitaste of monosodium glutamate (MSG) and the sourness of Fig. 2.Responses of Sensors Comprising Different Lipid Membranes to Six Basic Taste Substances and a Tested Drug SubstanceValues are mean±S.D (a) PC1(mV) (b) PC3(mV) Fig.3. Principal Component (PC) Analysis of Sensor Output Values forBasic Tastes and Tested Drug Substance (a) PC1: contribution rate: 48.1%, PC2: contribution rate: 20.8%; (b) PC3: contribu-tion rate: 15.6%, PC4: contribution rate: 12.6%. Values are mean±S.D.;reference solu-tion (), tanninc acid (●), MSG (◇), NaCl (◆), quinine HCl (O), propiverine HCl(A), citric acid (▲), sucrose(). Fig. 4.The Correlation between the Relative CPA Value of Quinine Solu-tion and the Bitterness Score Determined in Human Sensory Evaluation Values are mean±S.D.; Y=9.91X-19.8, R=0.998; quinine HCl (O), propiverineHCl (A), donepezil HCl (口), eperisone HCl (●), ticlopidine HCl (▲), azelastine HCl(). citric acid are readily identifiable as different tastes. Pro-piverine is confirmed to have a similar taste to quinine, aspropiverine and quinine are plotted at almost the same pointin the evaluation of PC1, PC2 and PC3. Meanwhile, Fig. 3bshows that quinine has a more bitter taste than propiverineaccording to PC4. Practical prediction of drug bitterness is important in thedrug development process. Figure 4 shows the correlationbetween the relative CPA value and the bitterness score de-termined in human sensory testing, when the propiverine so-lution was compared with a solution of a known bitter drug.The relative CPA value (vertical axis) of the bitterness sensorK523 represents the relative electric potential of the samplein relation to that of the quinine solution; a positive value in-dicates a more bitter taste than that of the quinine solution. Fig. 5. Effects of Masking Agents on Propiverine SolutionValues are mean±S.D.; **p<0.01 vs. control. From the relative CPA values, we could predict that thepropiverine solution was a little less bitter than donepezil so-lution but not as bitter as quinine solution. When the resultsfrom the taste sensor evaluation are compared with thosefrom human sensory testing, the two data sets are in closeagreement. In summary, the results of Figs. 2 and 3 suggest thatpropiverine hydrochloride has a bitter taste; the results ofFig. 4 predict the bitterness intensity of propiverine hy-drochloride and show good agreement between the predic-tions of the taste sensor and gustatory sensation testing. Ourresults confirm that the taste sensor can predict the taste of adrug without human sensory testing and suggest that thetaste sensor may be very useful in the formulation develop-ment of new chemical entities or hazardous drugs. Evaluation of Bitterness Suppression of Propiverine bythe Taste SensorFigure 5 shows the effects of maskingagents on the CPA values of the bitterness sensor K523 forpropiverine aqueous solution. The greatest bitterness-sup-pressing effect was shown by i-carrageenan, followed by a-carrageenan, and sucrose. K-Carrageenan had very little sup-pression effect at the concentrations used, while agar andpectin had no effect on propiverine solution, even thoughthey are also viscous polysaccharides. And, sucrose had neg-ligibly-small suppression effect, because the concentration ofsucrose was 9000 times higher than that of the other polysac-charides. The carrageenans seem to use the following sup-pression mechanisms: in aqueous solution carrageenans havenegatively-charged sulfate groups, while propiverine is acation. When carrageenan is added to propiverine solution,there is electrostatic interaction between them. In the oralcavity ionized propiverine binds to bitter taste receptors onthe mucous membrane, thereby giving a bitter taste. Theelectrostatic interaction between propiverine and the car-rageenan may decrease the contact between propiverine andthe mucous membrane in the oral cavity. Agar could not sup-press the bitter taste, because it is electroneutral. This fact in-dicates that just putting a viscous polysaccharide in the drugsolution is not going to suppress the bitterness taste. The rea-son for the i-carrageenan being more effective than the K-carrageenan can be explained by the number of sulfategroups, the K-carrageenan having one sulfate group and thei-carrageenan having two per an idealized disaccharide re-peating structure of the carrageenans. This theory does not,however, explain why the i-carrageenan suppresses bitternessmore effectively than the a-carrageenan, as A-carrageenan (a) Fig. 6.(a) CPA of Bitterness Sensor of Propiverine ODT at 15 s. (b) CPAof Bitterness Sensor of Propiverine ODT Soon after Full DisintegrationValues are mean±S.D.; **p<0.01,*p<0.05 vs. control. has three sulfate groups per subgroup. It is commonly con-sidered that the i-carrageenan and the K-carrageenan exist inhelical form in aqueous solution, and the sulfate groups faceoutside.1-34) Therefore, the drug molecule may be sand-wiched in between the sulfate groups of t-or K-carrageenan.In contrast, A-carrageenan exists in a random coil form inaqueous solution.5) The drug molecule interacting with thecarrageenan in a random coil form can uncouple more easilythan in the helical form. Therefore, l-carrageenan suppressesthe bitter taste of a drug molecule more effectively than A-carrageenan. While pectin has a carboxylic group, pectin inaqueouIsssolution seems to be in the ec ociolil form. iedrug-pectin interaction is weaker than the drug-carrageenaninteraction. Dynamic Evaluation of the Taste of Propiverine Hy-drochloride ODTFigure 6a shows the CPA values of bit-terness sensor K523 in the test medium 15 s after startingdisintegration of the propiverine ODTs with masking agents.From this result, it was predicted that the greatest bitterness-suppressing agent would be A-carrageenan, followed by t-carrageenan, pectin, agar, and K-carrageenan. It should benoted that polysaccharide powders, rather than dissolvedpolysaccharides, can suppress the bitter taste of drugs. Figure6a differs from Fig. 5 in the following respects: (1) A-car-rageenan suppresses the bitter taste more effectively than i-carrageenan, and (2) pectin and agar both suppress the bittertaste of drug in ODT. The former result (1) is attributed tothe rate of dissolution, with A-carrageenan acting more rap-idly than t-carrageenan because A-carrageenan dissolves inwater more rapidly. The carrageenan never suppress the bittertaste unless it dissolves. The latter result (2) is explained bythe disintegration rate. The disintegration times of the pro- Table 5. Disintegration Time of Propiverine Hydrochloride ODTs Form. Masking agent Disintegration time (s) Control 13.97 K-Carrageenan 14.04 t-Carrageenan 29.86 A-Carrageenan 25.02 4 Agar 32.71 5 Pectin 34.23 Fig. 7.The Correlation between the CPA Value of Bitterness Sensor andthe Bitterness Score Determined in Human Sensory Evaluation Soon afterFull Disintegration of the ODTs Values are mean±S.D.; Y=4.39X-2.70, R=0.907, p<0.005; control (O), K-car-rageenan (A), t-carrageenan (■), A-carrageenan (●), agar (口), pectine (). piverine ODTs with masking agents are shown in Table 5.ODTs containing pectin or agar disintegrated more slowlythan the ODT without these viscous polysaccharides. There-fore, the dissolution of propiverine from an ODT containingpectin or agar was lower by 15s after the start of disintegra-tion. Figure 6b shows the CPA values of the bitterness sensorK523 in the test medium after full disintegration of theODTs. From this result, it was predicted that the greatest ef-fect on bitterness suppression would be that of t-car-rageenan, followed by a-carrageenan and K-carrageenan.However, pectin and agar had no effect of bitterness suppres-sion. This result agrees with that obtained from Fig. 5. Figure 7 shows the correlation between the CPA value ofthe bitterness sensor and the bitterness score in gustatorytests soon after full disintegration of propiverine ODTs. Theregression formula is written in the figure. The correlationcoefficient (R) is 0.907. From this result, the predicted bitter-ness of ODTs using the taste sensor and the disintegrationtesting apparatus ODT-101 were found to be very similar tothe bitterness scores in gustatory tests. However, the bitter-ness scores of gustatory sensation varied widely, comparedwith the CPA values of the bitterness sensor. It may be con-cluded that this combination of taste sensor and ODT-101 ismore correct for measuring the taste of ODTs than thehuman sensory evaluation. In addition, it can be seen fromthe viewpoint of ensuring the safety of volunteers that thesensory evaluation should be replaced by the sensor meas-urement using the taste sensor and the ODT-101. The results from Figs. 6a and b indicate that the taste ofthe propiverine hydrochloride ODT is affected by the disinte-gration rate of ODT and the solubility rate of masking agent,and the taste changes as the ODT disintegrates. The relation- Time (s) Fig. 8. Relationship between CPA of Bitterness Sensor and DisintegrationTime of Propiverine ODT Control (O), K-carrageenan (△), t-carrageenan (■), A-carrageenan (●), agar(口),pectine (▲). ship between the CPA of the bitterness sensor and the disin-tegration time of the propiverine ODT is shown in Fig. 8.From the figure it may be deduced that the ODT containingA-carrageenan can fully suppress bitter taste of the propiver-ine up to 15 s after starting disintegration of the propiverineODTs. This result indicates that A-carrageenan is the bestmasking agent if the ODT is taken with a glass of plainwater. On the other hand, i-carrageenan suppresses the bittertaste by around 35% even after full disintegration of thepropiverine ODT. Therefore, t-carrageenan is the best mask-ing agent if the propiverine ODT is taken without water. Conclusions Methods for the effective utilization of a taste sensor in thedevelopment of a new medicine are presented. The taste ofpropiverine hydrochloride, a model drug substance whosetaste is unknown, could be predicted using a taste sensor.Good agreement between the predictions of the taste sensorand gustatory sensation testing has been shown. Our resultsconfirm that the taste sensor can predict the taste of a drugsubstance without human sensory testing. Next, the effect of masking agents for suppressing the bit-terness of propiverine hydrochloride could be predicted bythe taste sensor, with the greatest bitterness-suppressing ef-fect shown by t-carrageenan, followed by A-carrageenan. Finally, we evaluated the tastes of propiverine ODTs con-taining various polysaccharides in chronological order, byusing the taste sensor and the new disintegration testingapparatus ODT-101 in combination. The bitter taste ofpropiverine in the ODT containing A-carrageenan was fullysuppressed for up to 15s after the start of disintegration ofthe ODT. However, t-carrageenan was more effective than A-carrageenan in suppressing bitterness after full disintegrationof the ODT. The taste of the propiverine hydrochloride ODTchanged as the ODT disintegrated because the taste was de-termined by balance between disintegration rate of ODT andsolubility rate of masking agent. Just measuring taste afterdissolving ODT in medium is not going to evaluate in theprocess of disintegrating the ODT in the oral cavity. The re-sult using this combination oftaste sensor and the new disin-tegration testing apparatus showed good agreement with theresults of human gustatory sensation testing, thus demon-strating the usefulness and wide applicability of this combi-nation in the development of ODTs. ( References ) ( 1) U chida T., M iyanaga Y , Tanaka H., Wa d a K., Kur o saki S., Ohk i T., Yoshida M., Matsuyama K., Chem. Pharm. B u ll.,48, 1 8 43—1845(2000). ) 2) Uchida T., Kobayashi Y., Miyanaga Y., Toukubo R., Ikezaki H.,Taniguchi A., Nishikata M., Matsuyama K., Chem. Pharm. Bull., 49,1336—1339(2001). ( 3) M iyanaga Y . , Tanigake A., Nakamura T., Kobayashi Y., Ike z aki H.,Taniguchi A., Matsuyama K . , Uchida T . , Int. J. Pharm., 248, 207-218(2002). ) ( 4) Uchida T, T a nigake A., M iyanaga Y . , Matsuyama K., K u nitomo M. , K obayashi Y . , I kezaki H ., T aniguchi A . , J. P harm. P h armacol., 55 , 1479—1485(2003). ) 5) Ishizaka T., Miyanaga Y., Mukai J, Asaka K., Nakai Y., Tsuji E.,Uchida T., Chem. Pharm. Bull., 52, 943—948(2004). 6) AnandV, Kataria M., Kukkar V, Saharan V, Choudhury K. P, DrugDiscov. Today, 12,257—265(2007). 7) Kataoka M., Tokuyama E., Miyanaga Y., Uchida T., Int. J. Pharm.,351,36—44(2008). 8) Lorenz K. J., Reo P. J., Hendl O., Worthington H. J., Petrossian D. V,Int. J. Pharm., 367,65—72(2009). 9) Woertz K., Tissen C., Kleinebudde P, Breitkreutz J., J. Pharm. Bio-med. Anal.,51,497—506(2010) 10) Takagi S., Toko K., Wada K., Yamada H., Toyoshima K., J. PharmSci., 87,552—555(1998) 11) Takagi S., Toko K., Wada K., Ohki T., J. Pharm. Sci., 90, 2042—2048(2001). 12)Nakamura T, Tanigake A., Miyanaga Y., Ogawa T., Akiyoshi T., Ma-tsuyama K., Uchida T., Chem.Pharm. Bull., 50,1589—1593 (2002). 13)Miyanaga Y., Kobayashi Y., Ikezaki H., Taniguchi A., Uchida T., Sen-sors Mater,14,455—465(2002). 14)Hashimoto Y., Tanaka M., Kishimoto H., Shiozawa H., Hasegawa K.,Matsuyama K., Uchida T., J. Pharm. Pharmacol, 54, 1323—1328(2002). 15) Miyanaga Y., Inoue N., Ohnishi A., Fujisawa E., Yamaguchi M.,Uchida T., Pharm. Res., 20,1932—1938(2003). 16) Ogawa T., Nakamura T, Tsuji E., Miyanaga Y, Nakagawa H.,Hirabayashi H., Uchida T., Chem. Pharm. Bull., 52,172—177(2004). 17)Miyanaga Y., Mukai J., Mukai T., Odomi M., Uchida T., Chem.Pharm. Bull.,52,490—493(2004). ( Z heng Y. J., Keeney P. M. , Int. J. Pharm.,3 1 0,118—124(2006). ) Tsuji E., Uchida T, Fukui A., Fujii R., Sunada H., Chem. Pharm.Bull., 54,310—314(2006). 20)Tokuyama E., Shibasaki T., Kawabe H., Mukai J., Okada S., Uchida T.,Chem. Pharm. Bull., 54, 1288—1292(2006). 21)Ishizaka T., Okada S., Takemoto E., Tokuyama E., Tsuji E., Mukai J.,Uchida T., Chem. Pharm. Bull.,55,1452—1457 (2007). 22)Hashimoto Y, Matsunaga C., Tokuyama E., Tsuji E., Uchida T,Okada H., Chem. Pharm. Bull.,55,739—746(2007). 23)Agresti C., Tu Z., Ng C., Yang Y, Liang F. J, Eur. J. Pharm. Bio-pharm., 70,226—-233 (2008) ( 24) K obayashi Y. , H amada H., Y a maguchi Y. , I k ezaki H . , Toko K . , IEEJ T rans.,4,710—719 (2009). ) ( L elham C. N . , Sundelof O. L., I nt.J. Pharm., 115, 1 03—11 1 (19 9 5). ) ( 2 K atsuragi Y ., Mitsui Y., Umeda T., Otsuji K., Yamasawa S., K urihara K ., Pharm. Res.,14, 720—724(1997). ) ( 27) H arada T., Nakata H., PCT WO 03/074263. ) 28)Narazaki R., Harada T., Takami N., Kato Y., Ohwaki T., Chem. Pharm.Bull.,52,704707(2004). 29))BHarada T., Narazaki R., Nagira S., Ohwaki T, Aoki S., Iwamoto K.,Chem. Pharm. Bull.,54,1072—1075 (2006). 30)Harada T., Narazaki R., Ohwaki T., Uchida T., J. Drug Del. Sci. Tech.,(2010), in press. 31)AndersonN. S., CampbellJ. W, Harding M. M., Rees D. A., SamuelJ.W.B.,J. Mol. Biol.,45,85—99(1969). 32)Morris E. R., Rees D. A., Robinson G. O., J. Mol. Biol., 138, 349.362(1980). 33)Ikeda S., Morris V. J., Nishinari K., Biomacromolecules, 2, 1331-1337(2001). 34) Yuguchi Y., Thuy T.T. T., Urakawa H., Kajiwara K., Food Hydrocol-loids, 16, 512—522(2002). 35)De Ruiter G. A., Rudolph B., Trends Food Sci. Tech., 8, 389—395(1997). 本研究的目的是证明味觉传感器和新的崩解试验装置在口腔崩解片(ODTS)的研制以及苦味评价中的实用性和广泛适用性。样品:口腔崩解片(ODTS)仪器:日本INSENT电子舌SA402B检测指标:药物口味研究实验结果:本文介绍了日本INSENT味觉传感器(电子舌)在新药开发中的有效应用方法。首先,我们使用味觉传感器预测了盐酸丙氨酸(一种口味未知的模型药物)的味道。然后,我们筛选了掩蔽剂抑制盐酸丙氨酸苦味的能力,并用不同的掩蔽剂制备了盐酸丙氨酸的ODT,然后通过将味觉传感器与新的崩解测试装置ODT-101相结合,对这些ODT的口味进行了时序评价,以类似口腔窃听。因此,我们能够评价盐酸丙氨酸的味道和各种掩蔽剂在ODTS中的作用。(具体信息详见原文献A New Method for Evaluating the Bitterness of Medicines in Development Using a Taste Sensor and aDisintegration TestingApparatus)研究意义:本研究的目的是证明味觉传感器和新型崩解测试仪器在新药开发中的实用性和广泛适用性。近几年来口服崩解片对儿童或老年人来说很容易服用,在提高患者的依从性方面变得越来越重要。就含有令人不快的味道的药物而言,在配方设计中,对药物的味道和味觉屏蔽技术的评估似乎是显得尤为重要的。该味觉传感器与ODT-101相结合的实验结果与人体味觉检测结果吻合较好,证明了味觉传感器和崩解试验在新药开发中的有效性和适用性,为评价药品苦味研究建立了一种新的方法。

关闭-

1/6

-

2/6

还剩4页未读,是否继续阅读?

继续免费阅读全文北京盈盛恒泰科技有限责任公司为您提供《口腔崩解片中评价药品苦味检测方案(感官智能分析)》,该方案主要用于化药制剂中理化性质检测,参考标准《暂无》,《口腔崩解片中评价药品苦味检测方案(感官智能分析)》用到的仪器有电子舌。

我要纠错

推荐专场

感官智能分析系统(电子鼻/电子舌)

更多相关方案

咨询

咨询