方案详情文

智能文字提取功能测试中

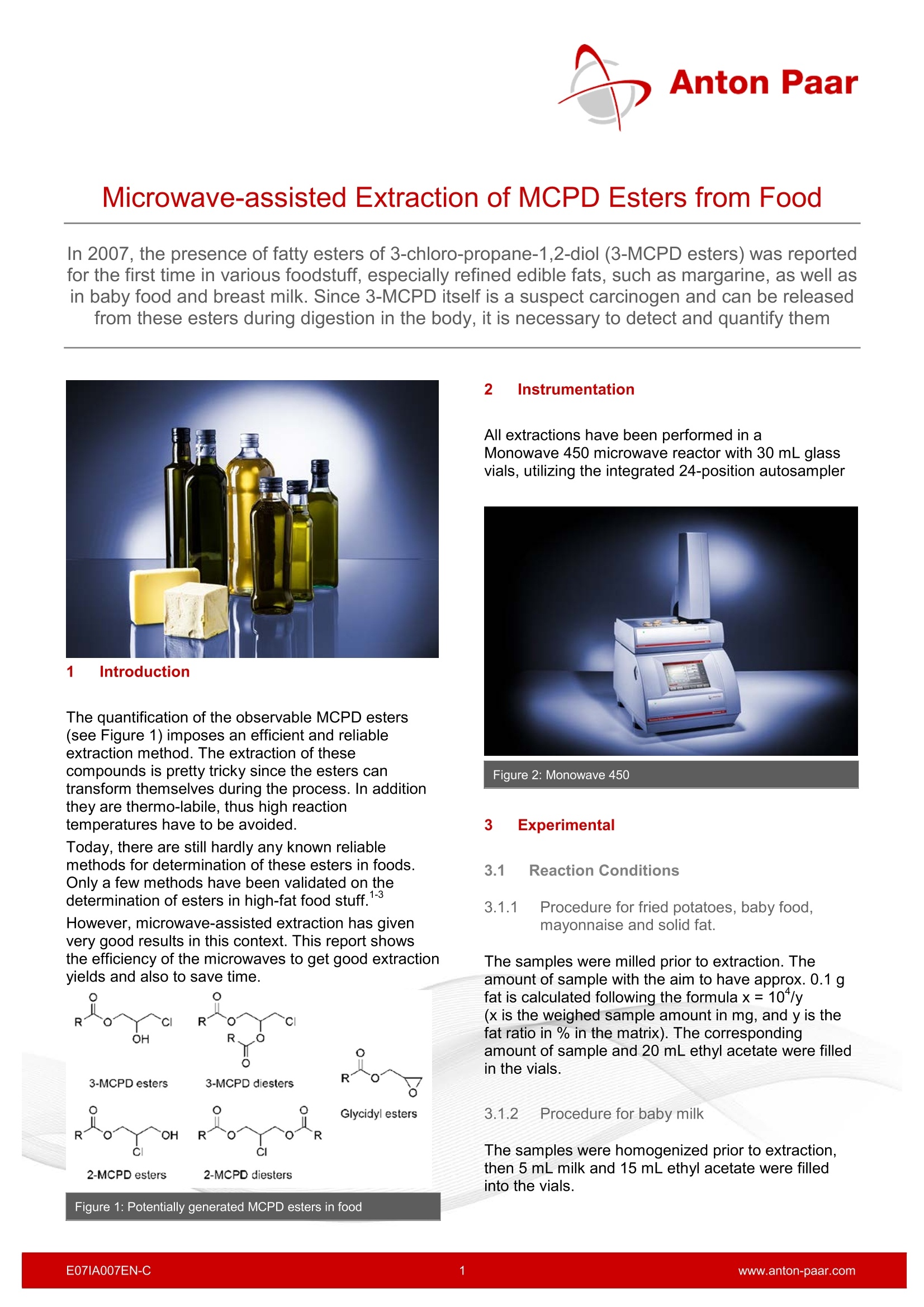

Anton Paar Introduction The quantification of the observable MCPD esterssee Figure 1) imposes an efficient and reliableextraction method.The extraction of thesecompounds is pretty tricky since the esters cantransform themselves during the process. In additionthey are thermo-labile, thus high reactiontemperatures have to be avoided. Today, there are still hardly any known reliablemethods for determination of these esters in foods.Only a few methods have been validated on thedetermination of esters in high-fat food stuff. However, microwave-assisted extraction has givenvery good results in this context. This report showsthe efficiency of the microwaves to get good extractionvields and also to save time. Figure 1: Potentially generated MCPD esters in food 2 Instrumentation All extractions have been performed in aMonowave 450 microwave reactor with 30 mL glassvials, utilizing the integrated 24-position autosampler Figure 2: Monowave 450 3Experimental 3.1 Reaction Conditions 3.1.1 Procedure for fried potatoes, baby food,mayonnaise and solid fat. The samples were milled prior to extraction. Theamount of sample with the aim to have approx. 0.1 gfat is calculated following the formula x= 10*/y(x is the weighed sample amount in mg, and y is thefat ratio in % in the matrix). The correspondingamount of sample and 20 mL ethyl acetate were filledin the vials. 3.1.2 Procedure for baby milk The samples were homogenized prior to extraction,then 5 mL milk and 15 mL ethyl acetate were filledinto the vials. The vials were placed in the autosampler andextracted for 10 minutes at 60°C with a standardstirring speed of 600 rpm. After cooling and filtrationthe extracted samples are analyzed following amethod adapted from the literature. 4 Results The validation of the method was done respecting thenorm NF-T90-210. An accuracy study of the method was done on 3concentration levels (0.02, 1 and 5 mg/kg forprocedure A, 0.0025, 0.05 and 0.2 mg/kg forprocedure B). For each level, the analysis wasrealized five times (reproducibilityconditions, differentdays), in double (repeatability conditions), and bydifferent operators. The achieved results aresummarized in Figures 3 and 4. Figure 3 shows the accuracy profiles of the recoveryrate of MCPD esters for the used potato matrices,Figure 4 shows the same for the baby milk samples.Tolerance intervals are given in %, the red dashedline indicates the maximum allowed deviationaccording to NF T90-210 proving the accuracy profileof the method 60%- a Figure 4: Obtained (a) 3-MCPD-, (b) 2-MCPD-, (C) Glycidylesters (in mg/kg) in baby milk 5 Conclusion Monowave 450 allowed efficient and reproducibleextraction of MCPD-and glycidyl esters from complexfat food matrix. The advantages of using a microwavereactor compared to a conventional oven forextractions are as follows: 1) Significant saving of time (10 min compared to16 h in the present application) 2) Automatic sample processing and documentationfor each vessel 3) Less solvent amounts required 4) Closed vessel conditions prevent evaporation ofthe solvent 5) Accuracy of the temperature sensor allowsimproved reproducibility ( [1] M. Kusters et al.,J. Agric. Food C hem. 2011, 59, 6263 ) ( [2] K . Yamazaki et al., Food Addit. Contam. 2013, 30 , 52 ) ( [3] A.P. Arisseto e t a l. , Food Addit. C ontam. 20 1 4, 31, 1385 ) ( [4] J. Kuhlmann, Eur. J. Lipid Sci. Technol.2011,113, 335 ) Contact Anton Paar GmbH Tel: +43 316 257-0 AN-Cwww.anton-paar.com Monowave 450可以从复杂的脂肪食品基质中高效且可再现地提取MCPD-和缩水甘油酯。 与常规烤箱相比,使用微波反应器进行提取的优势如下:1)节省大量时间(使用微波反应器只需10min,常规烤箱则需要16h)2)每个容器的自动样品处理和记录3)所需溶剂量少4)密闭容器条件防止溶剂蒸发5)温度传感器的准确性可提高重现性

关闭-

1/3

-

2/3

还剩1页未读,是否继续阅读?

继续免费阅读全文产品配置单

安东帕(上海)商贸有限公司为您提供《脂肪食品中氯丙醇检测方案(微波合成仪)》,该方案主要用于食用油脂制品中理化分析检测,参考标准《暂无》,《脂肪食品中氯丙醇检测方案(微波合成仪)》用到的仪器有安东帕微波合成仪Monowave400。

我要纠错

相关方案

咨询

咨询