方案详情文

智能文字提取功能测试中

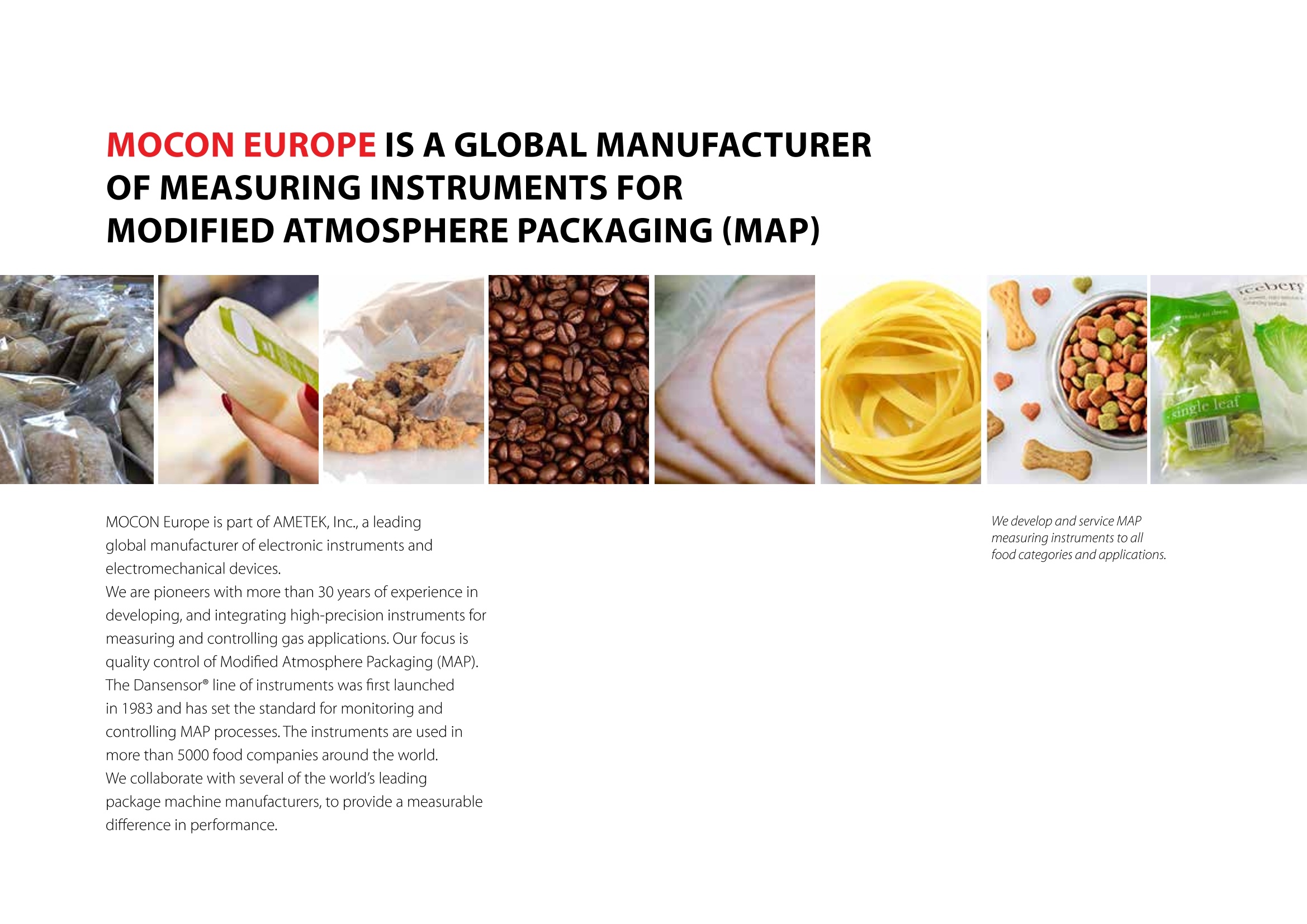

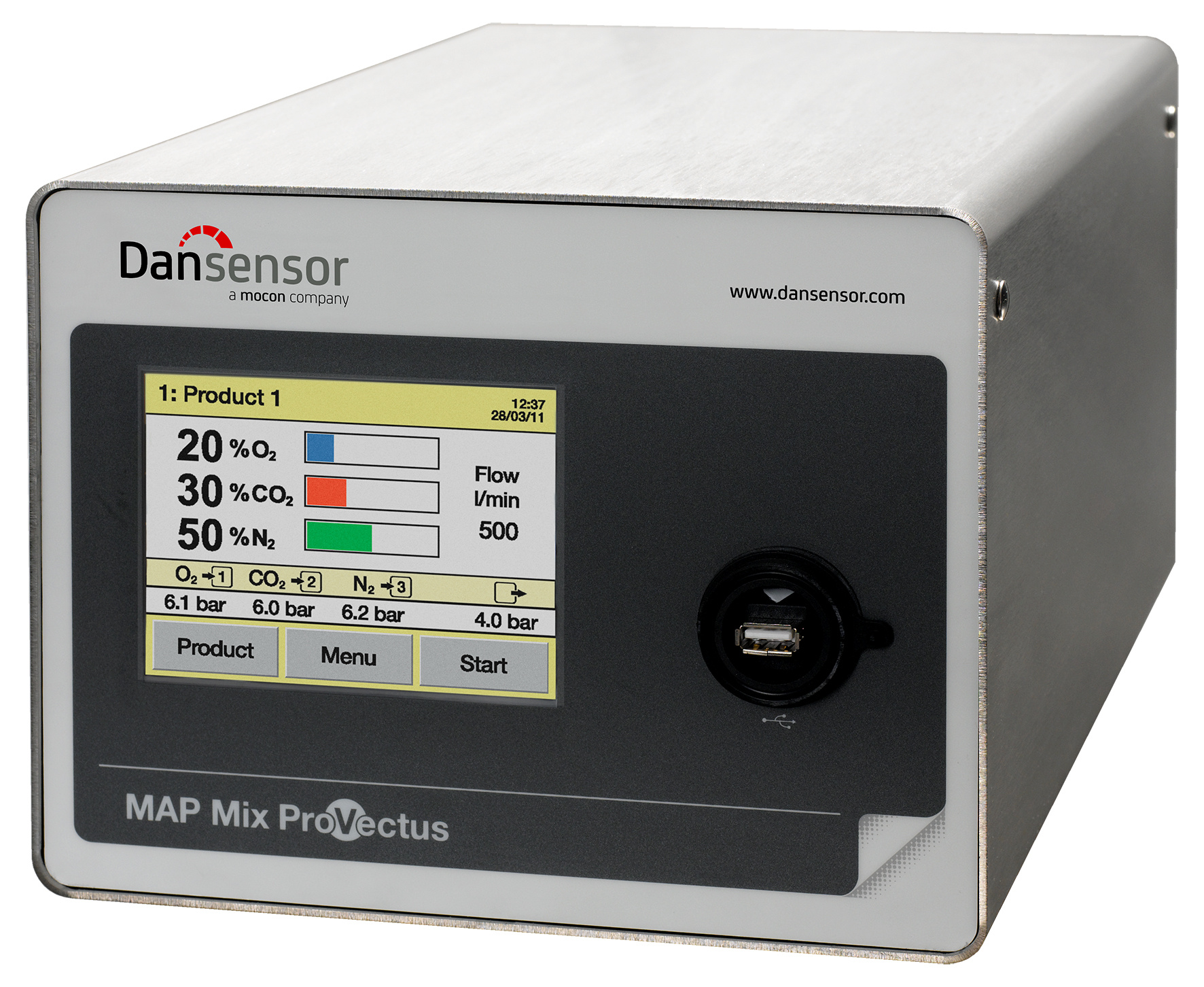

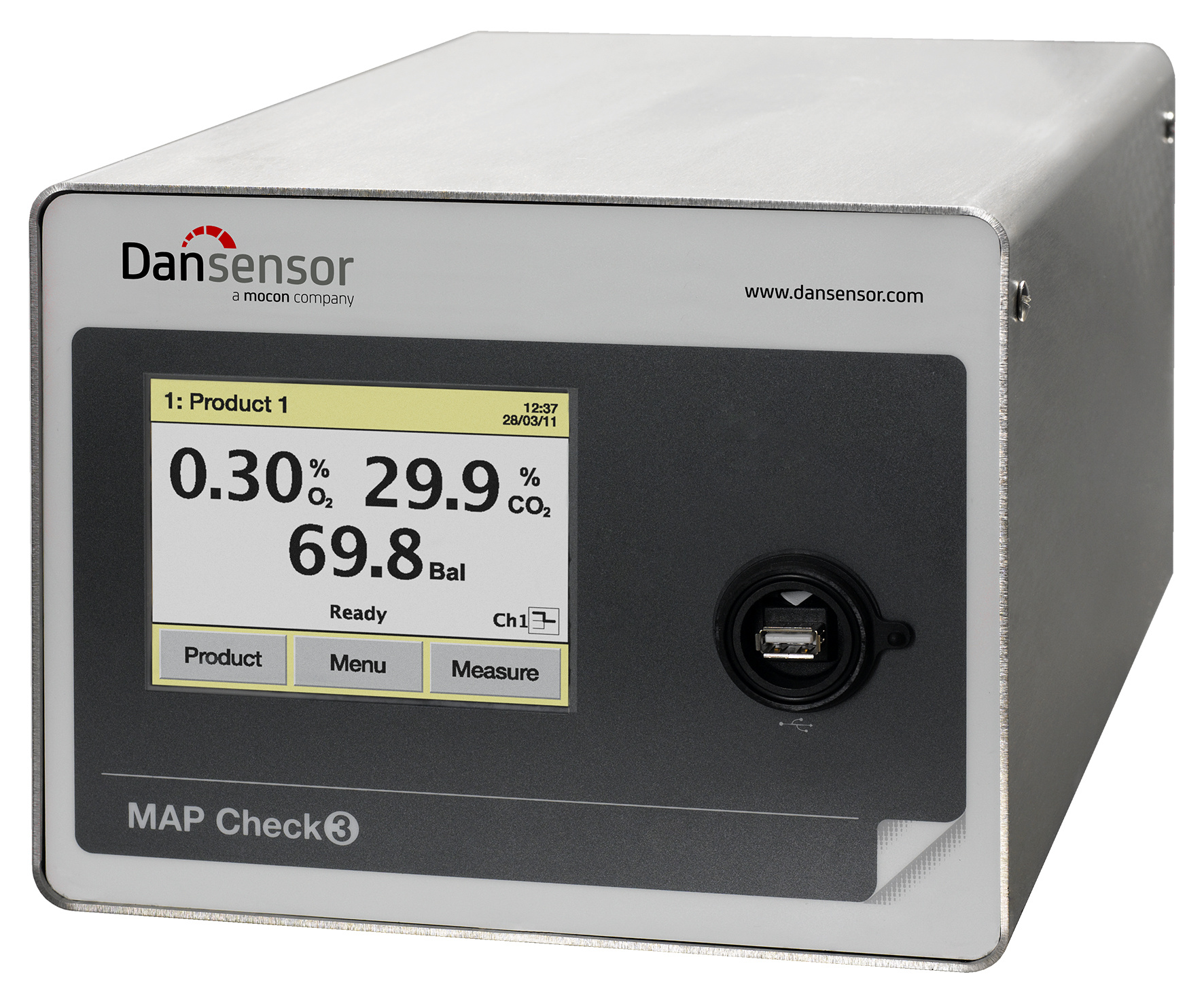

CHOOSE THE RIGHT SOLUTION FOR ADDINGVALUETOPACKAGING MACHINES SINCE1983 OPTIMIZE MAP PACKAGING MACHINE PERFORMANCEWITH ADVANCED GAS MONITORING AND CONTROL AMETEKlmocon MOCON EUROPE ISAGLOBALMANUFACTUREROF MEASURING INSTRUMENTS FORMODIFIED ATMOSPHERE PACKAGING (MAP) MOCON Europe is part of AMETEK, Inc., a leadingglobal manufacturer of electronic instruments andelectromechanical devices. We develop and service MAPmeasuring instruments to allfood categories and applications. We are pioneers with more than 30 years of experience indeveloping, and integrating high-precision instruments formeasuring and controlling gas applications. Our focus isquality control of Modified Atmosphere Packaging (MAP).The Dansensor line of instruments was first launchedin 1983 and has set the standard for monitoring andcontrolling MAP processes. The instruments are used inmore than 5000 food companies around the world.We collaborate with several of the world's leadingpackage machine manufacturers, to provide a measurabledifference in performance. THERE ARE SEVERAL BENEFITS OF INTEGRATING THE RIGHTMAP MONITORING AND CONTROL SOLUTION IN YOURPACKAGING MACHINERY PREPARED FORFUTURE DEMANDS Your customers will better be able to react to:-Changes in public legislation and demands,fx when accommodating market demandsfor sustainable packaging materials andpackaging types. -Demand for traceability and testing standards SAVE GAS AND MONEY Constant automated correction of gasmix and flow rate reduces gas waste andcost-and increases quality. MINIMIZE HUMAN ERRORS High precision automated gas controlassists the operator and prevents theoperator and prevent quality issues. EVERY DAY,USERS AROUND THE WORLD RELYONDANSENSORMAP SOLUTIONS MORE THAN 5000 DAILY USERS AND 33 YEARS OF KNOW-HOW OVERVIEWOF'DANSENSORSSYSTEM COMPONENTS FORINTEGRATION IN YOUR PACKAGING MACHINERY ON-LINE GAS ANALYZERS GAS MIXERS Automatically sample and monitor gas from theModified Atmosphere Packaging line. Ensure themachinery and gas mixing system deliver thedesired protective atmosphere. Automatically keep the right gas mixture andpressure at the appropriate flow rate. Mix carbon dioxide, oxygen and nitrogen. DansensorMAP Check 3 DansensorMAP Check 3 Vacuum Dansensor°ISM-3 Dansensor°MAP Mix Provectus Dansensor°MAP Mix 9001 ME Constant automatedgas flushing accordingto machinery speedpreventing unnecessary gasconsumption. SEAMLESS COMMUNICATIONBETWEEN INSTRUMENTSAND PACKAGING MACHINERY Various interface optionsensuring quick and efficient datatransmission between devices. This enables: Remote monitoring and instrumentcontrol from the packaging line's maincontrol panel or PLC Measurement and data logging to PCnetwork (Ethernet 10/100 Base T or USB) Single control point (central operatorpanel) for all monitoring andconfiguration (RS232) CONSTANT, CORRECT GAS FLOW Correct flow regardless of gaspressure Gas mix remains constant Automatically finds thedefined flow rate Automated, uniform gasmixture regardless of supplysources AUTOMATED CONSTANT SURVEILLANCE OF MACHINERY Continuous O2 and CO2 monitoring Assists the operator and reduceshuman error Dansensore MAP Check 3 On-line gas analyzer designed to continuously monitorand control gas content on vertical and horizontal flowpackaging machines. BENEFITS -Instant overview of gas flushing process - Stops the packaging machine if preset O2 and CO2 preset levelsare exceeded - Continuous monitoring of the gas mix during operation - Significant gas savings with optional GasSave function or whenpaired with Dansensor MAP Mix Provectus gas mixer - Logs and displays actual gas consumption with GasSave function for easy traceability -Quick change between several pre-configured product profilesduring operation FEATURES -Graphic 5"color touch display 一-Oxygen or combined oxygen and carbon dioxide measurement-User configurable alarms for low or high gas concentrations - Password protected menu for machine control parameterssettings -Storage of pre-configured product profiles - Data logging capabilities with USB or Ethernet -Extended remote monitoring and control options withModbus TCP -Ability to control Dansensor MAP Mix Provectus gas mixer - Optional built-in flow controller for dynamic gas flush control(GasSave) -Optional 3-channel multiplexer for sequential gas sampling indifferent points Dansensor@ MAP Check 3Vacuum On-line gas analyzer for quality assurance ofthermoforming and tray sealer machines. BENEFITS -Instant overview of the gas flushing process -Stops packaging machine if O2 and COz presetlevels are exceeded - Samples and monitors the gas mix in everypackaging cycle -Easy to configure different user access levels - Quick change between several pre-configuredproduct profiles during operation FEATURES -Graphic 5"color touch display -Oxygen or combined oxygen and carbondioxide measurement -User configurable alarms for low or high gasconcentrations -Password protected menu for setting upmachine control parameters -Storage of pre-configured product profiles -Data logging capabilities with USB or Ethernet - Ability to control the Dansensor MAP Mix Provectus gas mixer -Extended remote monitoring and controloptions with Modbus TCP -Optional measurement of buffer tank gas mixand pressure Dansensore MAP Mix Provectus Automatic gas mixer using dynamic mixing principle foruniversal use with different types of packaging machines. BENEFITS -Intuitive set-up and operation 一-On the fly change between pre-configured gas mixes, no needfor fine-adjustments -Maintains stable outlet gas flow and accurate gas mix regardless of fluctuations and reduction in gas supply pressure-Automatically compensates for different pressure levels in thegas inlets. Allows supply from e.g. N2 generator combined withgas bottle. -Meets traceability requirements by storing accurateinformation about current gas flow, gas mix and consumptionover time. - Single point of operation and configuration wheninterconnected with Dansensor MAP Check 3 gas analyzer- Possible gassave operation on flow packaging machines when controlled by MAP Check 3 FEATURES - Mixes any 2 or 3 gas blend of oxygen, nitrogen, carbon dioxideand air - Dynamic gas flow control -Minimal pressure drop from inlet to outlet -Wide gas inlet pressure range and high outlet flow capacity (up to 1500 l/min for 3-gas version) - Stores up to 10 pre-configured gas mixes -Data logging to USB or PC network of gas mix-and consumption date and time during operation -Possibility for remote monitoring and control with Modbus TCP -Controllable from MAP Check 3/MAP Check 3 Vacuum analyzer -15L buffer tank available for thermoformers and tray sealers DansensoreSM-3 Compact sensor module for basic oxygen monitoring BENEFITS -Continuous clear indication of the measurecd O2 level - Measuring range: 1 ppm-100% (std. 0-20.9%)- suited formeasuring purity levels in gas generators - High reliability and accuracy - better than ± 1% of reading-Low maintenance demand -Self-diagnostic, automatic monitoring of vital parameterswith audio alarm FEATURES -2 oxygen concentration alarms - Available as stand-alone instrument or for system integration with remote operation and display panel-Sample gas supply by gas pressure or internal pump(specific instrument versions) -Different set-upoptions for adaptation to the analyzerapplication -0/4-20 mA as standard (optional:0-10V) MAP Mix 9001ME Manually operated gas mixer suited for mosttypes of packaging machines. BENEFITS -Mixes any 2 or 3 gas blend of oxygen,nitrogen,carbon dioxide -Reliable design based on proportional mixingprinciple -Sufficient flow capacity for most low/medium speedpackaging machines -Easy setting of gas mix by adjustment dials -Clear indication if gas supply pressure is low or outlet flow cannot be maintained -Low total cost of ownership with minimummaintenance FEATURES -2 or 3 gas versions -Flow ranges from 20-400 I/min - Pressure/buffer version for tray sealing andthermoforming machines -Version with flow adjustment for flow packagingmachines -LED indication of gas inlet pressure alarm and gasoutlet flow alarm - Alarm relay and built-in buzzer -Option: 151buffer tank available for use withthermoformers or tray sealers VERTICAL FLOW PACKAGING MACHINES (VFFS) CONTINUOUS GAS MONITORING OPTIONS ISM-3 Constant real time O2 level reading MAP Check 3 (gas save)O2 and CO2 monitoring-Switch between multiple pre-config-ured product profiles on the fly-Built-in GasSave for dynamic gas flushflow control CHiPS GAS MIXINGOPTIONS MAP Mix ProvectusHigh speed and high capacity mixer-Consistent output, even withfluctuating gas supply-Easy to change between multipledefined gas mixes oc MAP Mix 9001 ME Operate at moderate speed with rarechange of gas mix MONITORING/GAS MIXING /GAS CONTROLCOMPLETE SOLUTION MAP Check 3 MAP Mix Provectus Interconnect MAP Check 3 and MAPMix Provectus for Gas Monitoring, GasControl and Gas Mixing, operated locallyor remotely from the central operatorpanel. Ensuringcontrol of the entire MAPprocess integrated in the machine HORIZONTAL FLOW PACKAGING MACINES (HFFS) MONITORING/GAS MIXING/GAS CONTROL COMPLETE SOLUTION MAP Check 3 MAP Mix Provectus Interconnect MAP Check 3 and MAP Mix Provectus for Gas Monitoring, Gas Control and Gas Mixing, operated )land( locally or remotely from the central operator panel.Ensuring control of the entire MAP process integrated in the machine TRAY SEALER (TS) THERMOFORMER(TF) LET'S GET IN TOUCH Steen Lydeking Andersen Global OEM Sales Manager oem.dk.mocon@ametek.com CLICK HERE MOCON Europe A/S(OEM Centre of Excellence)Ronnedevej 18DK-4100 RingstedDENMARKTel:(+45) 57 66 00 88Email: info.dk.mocon@ametek.com MOCON,Inc.-Headquarters 7500 Mendelssohn Avenue NorthBrooklyn Park, MN 55428USATel:+1.763.493.6370Fax:+1.763.493.6358Email: info.mocon@ametek.com AMETEK GmbHAMETEK S.r.I.(MOCON Business Unit)(MOCON Business Unit)Carl-Borgward-StraBe 10Via della Liberazione, 2456566 Neuwied20068 Peschiera Borromeo (MI)GERMANYITALYTel: +49 2631 3933 0Tel:(+39)02 946931Fax: (+49) 2631 3933 33Fax: (+39) 02 94693650Email: info.de.mocon@ametek.comEmail: info.it.mocon@ametek.comAMETEK S.A.SAMETEK INSTRUMENTOS,S.L.U.(MOCON Business Unit)(MOCON Business Unit)Rond Point de I'Epine des Champs Buroplus, Bat DEsteve Terradas, 31 -Local 978990 ELANCOURT08023 BarcelonaFRANCESPAINTel: (+33) 1 69 56 58 50Tel:(+34) 93 2052286Email: info.fr.mocon@ametek.comFax:(+34) 932 804 027 Email: info.es.mocon@ametek.com ORIGINAL EQUIPMENT MANUFACTURER OF DANSENSORINSTRUMENTS AMETEK°mocon 您的包装机械中拥有MAP监测和控制解决方案的几个好处 帮助客户随时应对挑战 适应市场对可持续包装材料和包装类型的变化要求,面对可追溯和检测标准的要求,您的客户都将放心地应对这些法规和需求的变化。 经济之选、提高生产质量 气体混合和流量的持续性和自动校正功能减少了气体浪费;当出现异常情况时,在线监控和自动警报会停止包装线,减少材料和产品浪费从而节约成本并提高了产品质量。 自动化,避免人为质量问题 高精度自动气体控制辅助操作员,防止操作员失误出现质量问题。MOCON是气调包装(MAP) 测量仪器的全球制造商,在气调包装 (MAP) 的质量控制领域,我们拥有近40年用于测量和控制气体应用的高精度仪器的开发和集成经验。Dansensor®系列仪器于1983年一经推出,就为监测和MAP过程控制树立了标准。

关闭-

1/17

-

2/17

还剩15页未读,是否继续阅读?

继续免费阅读全文产品配置单

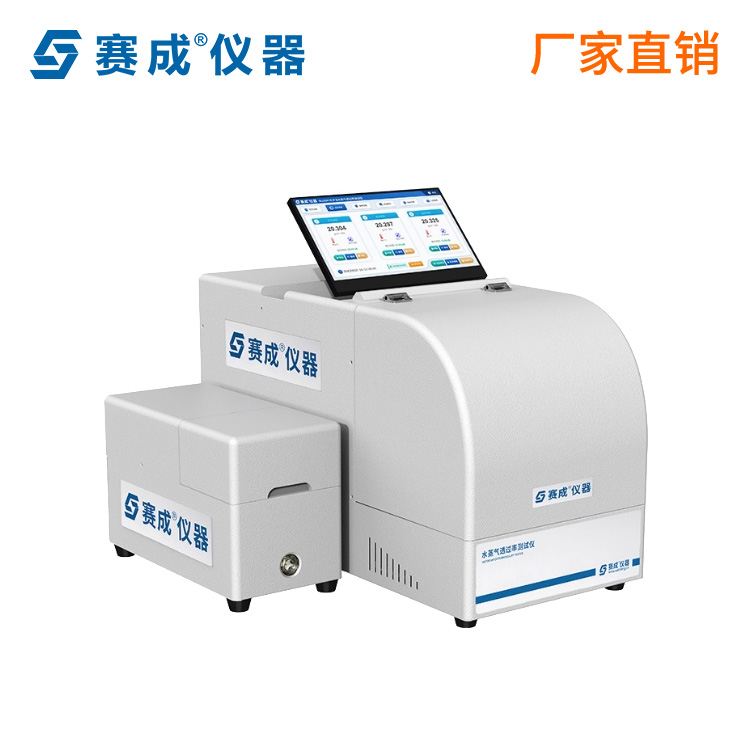

阿美特克膜康为您提供《食品包装在线MAP监测和控制解决方案》,该方案主要用于包装中顶空气体分析,包装密封性检测,参考标准《暂无》,《食品包装在线MAP监测和控制解决方案》用到的仪器有膜康数字式气体混配器、膜康在线顶空分析仪、膜康水蒸气透过率测试仪PERMATRAN-W® Model 3/34、膜康(MOCON)医疗包装件密封测试仪、Dansensor 负压法密封性测试仪。

我要纠错

相关方案

咨询

咨询