碳酸果汁饮料中气体体积和空气含量检测方案(饮用酒检测仪)

检测样品 碳酸饮料(汽水)

检测项目 理化分析

方案详情文

智能文字提取功能测试中

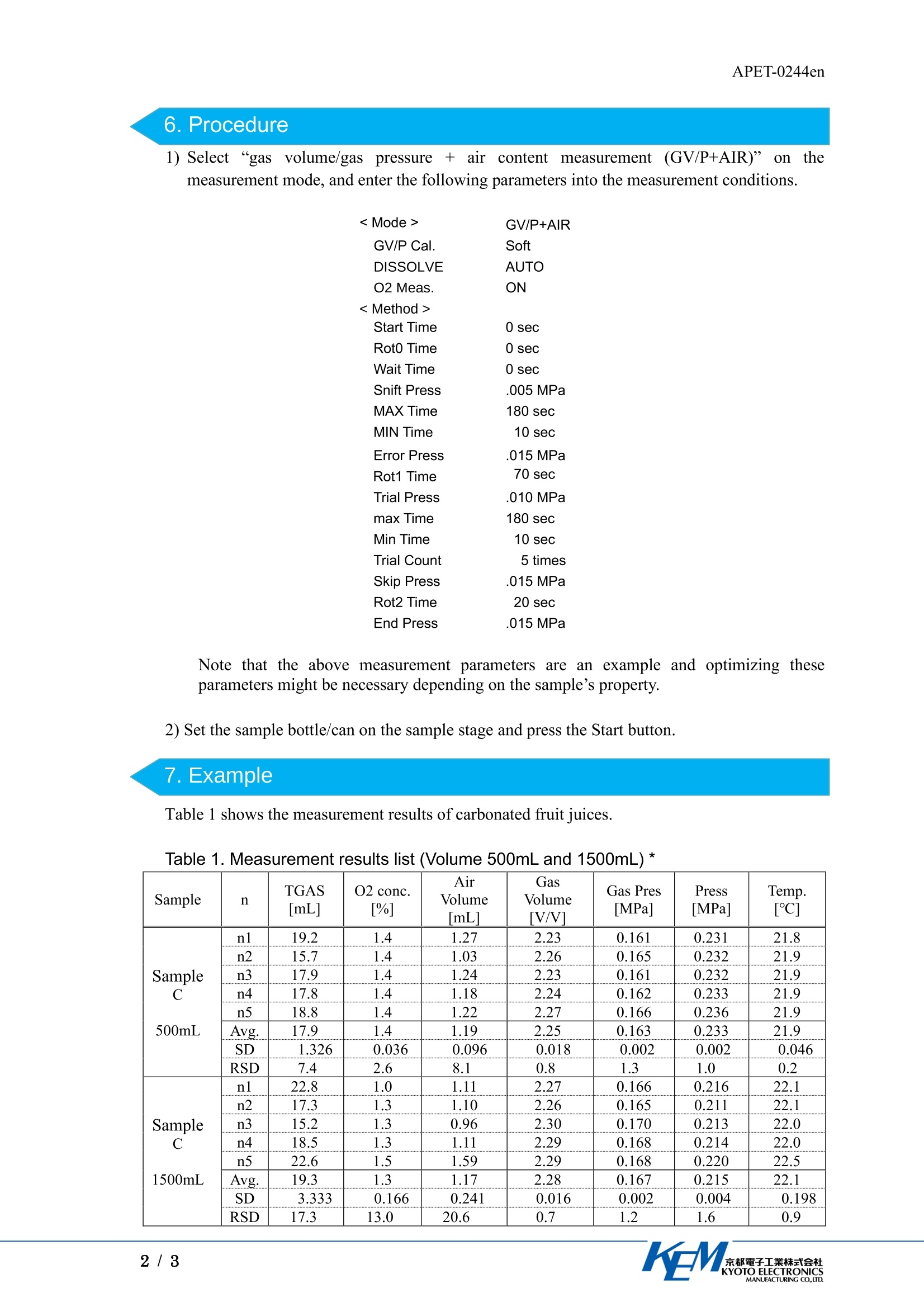

二氧化碳气容量测试仪测量不同容器碳酸果汁饮料中的气体体积和空气含量 应用资料测量碳酸饮料的气体体积、空气含量和氧气浓度是决定口感、味道和风味以及最佳日期的重要因素。本应用介绍了使用二氧化碳气容量分析仪测量两种不同尺寸容器的市售碳酸果汁饮料。通过连续旋转样品容器并测量气体的平衡压力和样品温度来计算气体体积。然后,样品中的气体被转移到吸收筒中,二氧化碳气体被填充在吸收筒中的吸收溶液(氢氧化钠溶液)吸收,以测量空气含量和氧气浓度。京都電子工業株式会社KYOTO ELECTRONICSAPET-0244erMANUFACTURING CO.,LTD. APET-0244er6. Procedure Application Note Measurements of gas volume and air content incarbonated fruit juice beverages of different sizecontainers (500mL, 1500mL) by Gas volume analyzer Industry Instrument Measurement method Standards Food & beverageGas Volume and Air Content AnalyzerGas volume measurement methodGB/T 10792 1.Scope Caution This instrument needs a 6 mol/L sodium hydroxide aqueous solution which may causeblindness when it contacts human eyes. Be sure to wear protective goggles duringhandling it. The measurement of the gas volume, air content, and oxygen concentration of carbonatedbeverages is an important factor in determining the mouthfeel, taste and flavor, and best-by dateThis Application Note introduces an example of measuring commercially available carbonatedfruit juice beverages of two different size containers using a gas volume and air content analyzer.The gas volume is calculated by continuously rotating the sample container and measuring theequilibrium pressure of the gas and the sample temperature. Then, gas in the sample is transferredto the absorbent cylinder and the carbon dioxide gas is absorbed by an absorbent solution (sodiumhydroxide solution) filled in the cylinder to measure the air content and oxygen concentration. 2. Precautions The instrument and samples should be sufficient temperature equilibration with the laboratoryroom temperature where is maintained at a constant temperature. Either the instrument air system or an independent air compressor, both of which can adjustin the pressure range between 0.5 and 0.7 MPaG, is required for piercing and rotating samplebottle/can. ●When measuring samples containing solids like the pulp of small fruits, wash the nozzle afterevery 5-10 measurements to prevent clogging of the tubing. 3. After measurement ●Samples should be disposed of properly after the measurement is complete, as they may becontaminated with the absorbent solution. The measurement instrument should be rinsed properly at the end of the day. ●When measuring samples containing solids such as pulp, clean the net filter of the instrumentafter measurement for the day is complete. 4. Apparatus Equipment Gas volume and air content analyzer Option Oxygen concentration measurement unit 5. Reagents Absorbent solution 6 mol/L sodium hydroxide solution Rinse solution Pure water 1) Select66gasVvolume/gaLsSpressuree十air content measurement((GV/P+AIR)”9onnthemeasurement mode, and enter the following parameters into the measurement conditions. End Press .015 MPa Note that the above measurement parameters are an example and optimizing theseparameters might be necessary depending on the sample’s property. 2) Set the sample bottle/can on the sample stage and press the Start button. 7.Example Table 1 shows the measurement results of carbonated fruit juices. Table 1. Measurement results list (Volume 500mL and 1500mL) * Sample n TGASmLI O2 conc.[%] AirVolume[mL1 GasVolume[V/V1 Gas PresMPa| PressMPa Temp.「C1 SampleC 500mL nl 19.2 1.4 1.27 2.23 0.161 0.231 21.8 n2 15.7 1.4 1.03 2.26 0.165 0.232 21.9 n3 17.9 1.4 1.24 2.23 0.161 0.232 21.9 n4 17.8 1.4 1.18 2.24 0.162 0.233 21.9 n5 18.8 1.4 1.22 2.27 0.166 0.236 21.9 Avg. 17.9 1.4 1.19 2.25 0.163 0.233 21.9 SD 1.326 0.036 0.096 0.018 0.002 0.002 0.046 RSD 7.4 2.6 8.1 0.8 1.3 1.0 0.2 SampleC 1500mL n1 22.8 1.0 1.11 2.27 0.166 0.216 22.1 n2 17.3 1.3 1.10 2.26 0.165 0.211 22.1 n3 15.2 1.3 0.96 2.30 0.170 0.213 22.0 n4 18.5 1.3 1.11 2.29 0.168 0.214 22.0 n5 22.6 1.5 1.59 2.29 0.168 0.220 22.5 Avg. 19.3 1.3 1.17 2.28 0.167 0.215 22.1 SD 3.333 0.166 0.241 0.016 0.002 0.004 0.198 RSD 17.3 13.0 20.6 0.7 1.2 1.6 0.9 * Measurement items Gas Volume Carbon dioxide volume (mL) of 1mL sample volume Air Volume Gas volume except carbon dioxide in sample bottle/can (mL) Gas Press Converted pressure in sample bottle/can at 20 ℃(MPa) Press Measured pressure (MPa) Temp. Measured sample temperature (°C) 京都电子工业株式会社-可睦电子(上海)商贸有限公司电话: 021-54488867 电邮: kemu-kem@163.com 都電子工業株式会社KYOTO ELECTRONICSMANUFACTURING CO.,LTD

关闭-

1/3

-

2/3

还剩1页未读,是否继续阅读?

继续免费阅读全文产品配置单

可睦电子(上海)商贸有限公司-日本京都电子(KEM)为您提供《碳酸果汁饮料中气体体积和空气含量检测方案(饮用酒检测仪)》,该方案主要用于碳酸饮料(汽水)中理化分析检测,参考标准《暂无》,《碳酸果汁饮料中气体体积和空气含量检测方案(饮用酒检测仪)》用到的仪器有GVA-710 全自动饮料二氧化碳气容量测定仪。

我要纠错

推荐专场

相关方案

咨询

咨询