方案详情文

智能文字提取功能测试中

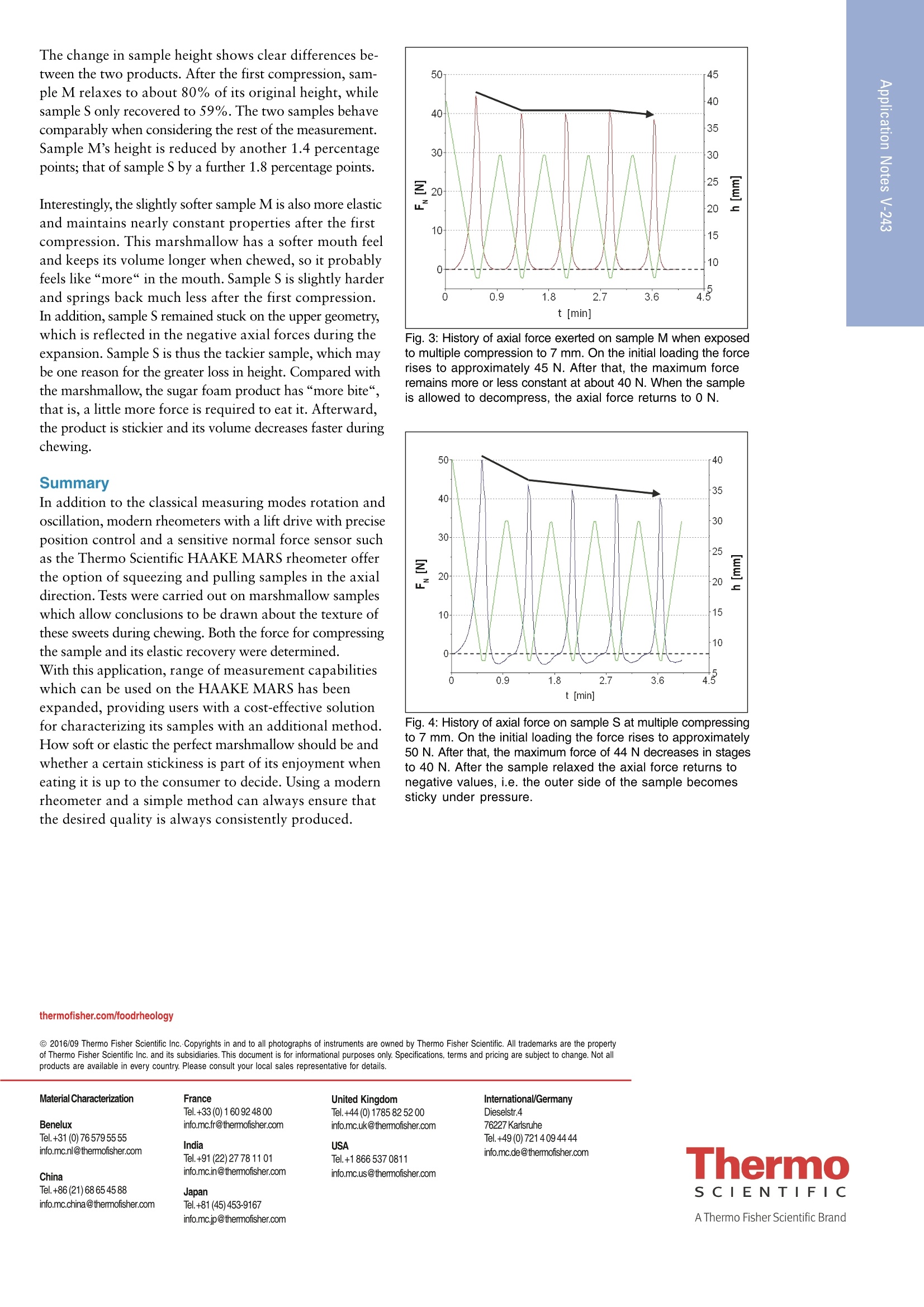

AThermo Fisher Scientific Brand Klaus Oldorp, Thermo Fisher Scientific, Material Characterization, Karlsruhe, Germany We use many of our senses to experience our food. Fora food product to be popular and therefore successful,it must meet many requirements: it has to look appealing,smell good, have a pleasant texture in the mouth-or“mouth feel"-and of course taste good. As soon as a foodproduct is perceived as being “unpleasant" during evenone of these subjective “tests,“ it can quickly lead toconsumer rejection. When regarding natural products like bread, meat orcheese, certain fluctuating or individual“bad" qualities aresometimes accepted, such as the smell of certain cheeses.However for industrially-produced foodstuffs, and par-ticularly when dealing with treats such as sweets, all of theabove criteria have to be met to gain consumer acceptance.No matter how good something looks or tastes, the"mouth feeling,“i.e. the texture in the mouth, has to beright, otherwise the pudding will remain on the shelf inthe refrigerated section and the cookies will never be purchased. Marshmallows are another example of food where notonly the flavour and sweetness, but also the“bite“, iscritical for enjoyment. Using a rheometer or a testingmachine such as a texture analyzer, this consistency ortexture can be described using objective parameters andthus making quality control or targeted improvementpossible. A modern rheometer allows various optionsfor characterising marshmallows and similar products.It also allows the viscosities of the starting materials to bemeasured, and the finished product can be characterizedin an oscillatory test. By combining a sensitive normal force sensor with a high- precision lift drive, the Thermo ScientificTM HAAKETMMARSTM provides the additional option of stressingsamples axially, i.e. by exerting a vertical force on themfrom above at a maximum of 50 N (which correspondsto a weight of 5 kg) by either pressing on or pulling themarshmallow sample. In this type of situation, the ThermoScientific HAAKE MARS measures the axial force andposition of the measurement geometry precisely while thesample is being squeezed, or the penetration of a probe intothe sample is tracked. Fig. 1: Samples M (left) and S (right) before measurement. Fig. 2: Samples M (left) and S (right) during measurement. Measurements and Results Two products were compared during the experiment.Marshmallows (M) of about 30 mm in height and a sugarfoam product (S) of about 10 mm in height. In order tocompare the absolute values discs were cut from productS matching the diameter of the marshmallows and werestacked three high (Fig. 1). A 35 mm-diameter plate as usedfor rotational and oscillation measurements was run downto a height of 7 mm (Fig. 2) at a speed of 1 mm, and thenrun back up to 30 mm at 1 mm/s. This process was repeatedon the samples five times in a row to simulate chewing inthe mouth. When compressing first sample M, the force increased toabout 45 N before dropping again. During the followingcycles the force only reached about 40 N but remainednearly constant through each cycle. A force of 50 N isrequired to compress sample S; the sample is thus felt tobe somewhat harder. The maximum applied force decreasesthroughout subsequent cycles, dropping from 44 N duringthe second cycle to 40 N during the fifth cycle. The change in sample height shows clear differences be-tween the two products. After the first compression, sam-ple M relaxes to about 80% of its original height, whilesample S only recovered to 59%. The two samples behavecomparably when considering the rest of the measurement.Sample M’s height is reduced by another 1.4 percentagepoints; that of sample S by a further 1.8 percentage points. Interestingly,the slightly softer sample M is also more elasticand maintains nearly constant properties after the firstcompression. This marshmallow has a softer mouth feeland keeps its volume longer when chewed, so it probablyfeels like “more" in the mouth. Sample S is slightly harderand springs back much less after the first compression.In addition, sample S remained stuck on the upper geometry,which is reflected in the negative axial forces during theexpansion. Sample S is thus the tackier sample, which maybe one reason for the greater loss in height. Compared withthe marshmallow, the sugar foam product has "more bite",that is, a little more force is required to eat it. Afterward,the product is stickier and its volume decreases faster duringchewing. Summary In addition to the classical measuring modes rotation and oscillation, modern rheometers with a lift drive with preciseposition control and a sensitive normal force sensor suchas the Thermo Scientific HAAKE MARS rheometer offerthe option of squeezing and pulling samples in the axialdirection. Tests were carried out on marshmallow sampleswhich allow conclusions to be drawn about the texture ofthese sweets during chewing. Both the force for compressingthe sample and its elastic recovery were determined.With this application, range of measurement capabilitieswhich can be used on the HAAKE MARS has beenexpanded, providing users with a cost-effective solutionfor characterizing its samples with an additional method.How soft or elastic the perfect marshmallow should be andwhether a certain stickiness is part of its enjoyment wheneating it is up to the consumer to decide. Using a modernrheometer and a simple method can always ensure that the desired quality is always consistently produced. Fig. 3: History of axial force exerted on sample M when exposedto multiple compression to 7 mm. On the initial loading the forcerises to approximately 45 N. After that, the maximum forceremains more or less constant at about 40 N. When the sampleis allowed to decompress, the axial force returns to 0 N. Fig. 4: History of axial force on sample S at multiple compressingto 7 mm. On the initial loading the force rises to approximately50 N. After that, the maximum force of 44 N decreases in stagesto 40 N. After the sample relaxed the axial force returns tonegative values, i.e. the outer side of the sample becomessticky under pressure. thermofisher.com/foodrheology 2016/09 Thermo Fisher Scientific Inc.Copyrights in and to all photographs of instruments are owned by Thermo Fisher Scientific. All trademarks are the propertyof Thermo Fisher Scientific Inc. and its subsidiaries. This document is for informational purposes only. Specifications, terms and pricing are subject to change. Not allproducts are available in every country. Please consult your local sales representative for details. Material Characterization Benelux FranceUnited KingdomInternational/GermanyTel.+33 (0) 160 92 4800Tel.+44(0) 1785 82 5200Dieselstr.4info.mc.fr@thermofisher.cominfo.mc.uk@thermofisher.com76227KarlsruheTel.+49 (0) 721 4 09 44 44IndiaUSAinfo.mc.de@thermofisher.comTel.+91 (22)27 78 11 01Tel.+1 866 5370811info.mc.in@thermofisher.cominfo.mc.us@thermofisher.comJapanTel.+81 (45)453-9167 We use many of our senses to experience our food. Fora food product to be popular and therefore successful,it must meet many requirements: it has to look appealing,smell good, have a pleasant texture in the mouth - or“mouth feel“ - and of course taste good. As soon as a foodproduct is perceived as being “unpleasant“ during evenone of these subjective “tests,“ it can quickly lead toconsumer rejection.

关闭-

1/2

-

2/2

产品配置单

上海珩泽科技有限公司为您提供《棉花糖中弹性检测方案(流变仪)》,该方案主要用于糖果中理化分析检测,参考标准《暂无》,《棉花糖中弹性检测方案(流变仪)》用到的仪器有HAAKE MARS iQ 流变仪。

我要纠错

相关方案

咨询

咨询