方案详情文

Electrostatic, rotating bell (ESRB) application is one of the most important coating application techniques

for industries with demanding specifications for optical attractiveness of coatings, such as automotive. The

ESRB process involves production of droplets using a high-speed rotating bell, which are subsequently

transported to the substrate being coated via shaping air [1-3]. An electrical potential is applied between the

bell and the substrate which further helps droplet atomization and transport. This research investigates the

effects of inertia, centrifugal force, drag force, and electrostatic force on the atomization mechanism and

particle size distribution using an automotive OEM base coat formulation. Coating flow rate (CFR), shaping

air flow rate (SAFR), bell speed (BS), and electrostatic potential (EP) were used as primary parameters to

create various atomization conditions and particle size distributions. The atomization mechanism, ligament

formation, and particle size distribution were measured using high-speed laser shadowography and image

processing. The effects of governing forces and particle size generated on efficiency of droplet transfer to the

substrate and optical appearance of the coatings were studied to generate operating windows for optimum

process efficiency and appearance.

智能文字提取功能测试中

关闭产品配置单

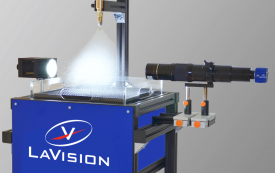

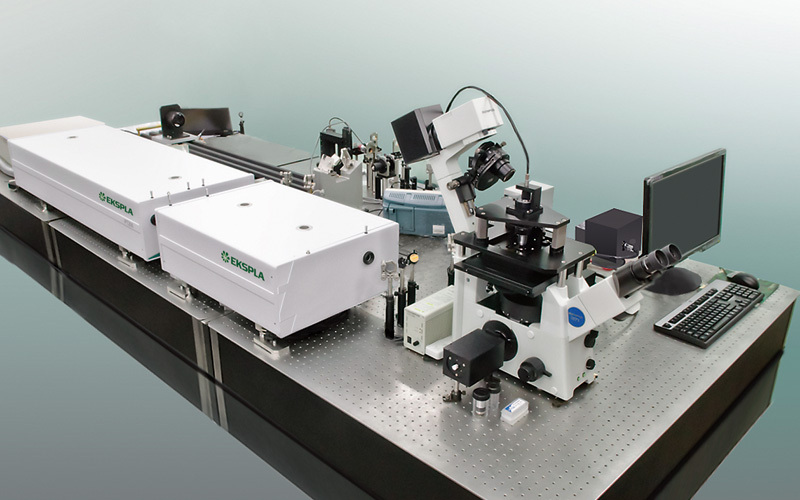

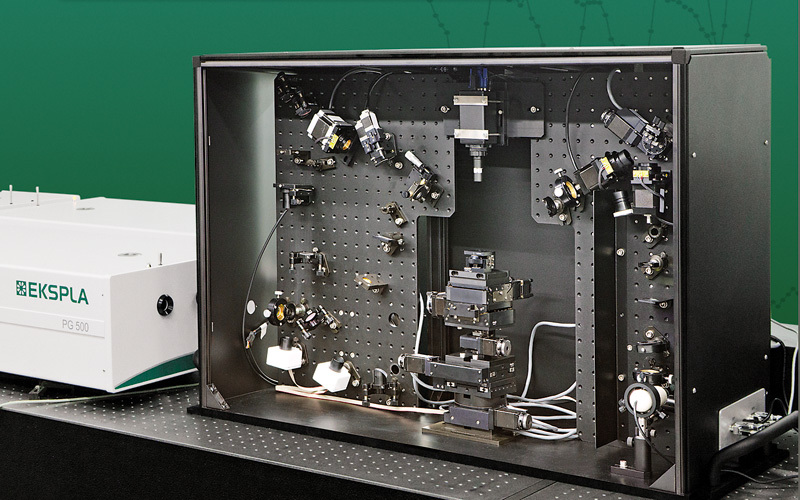

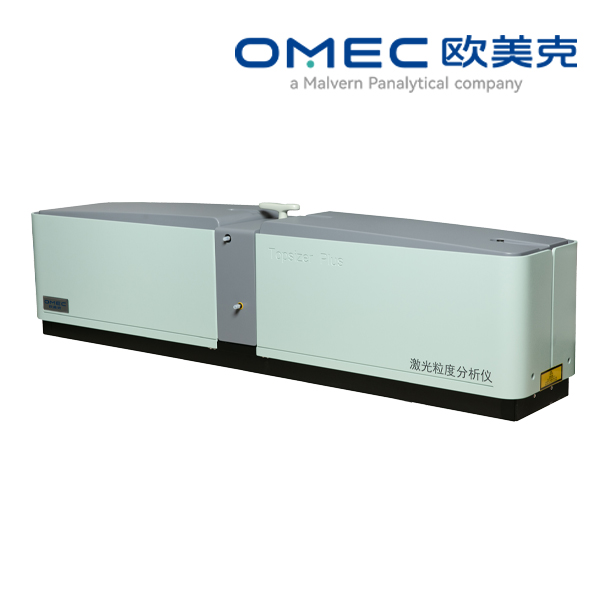

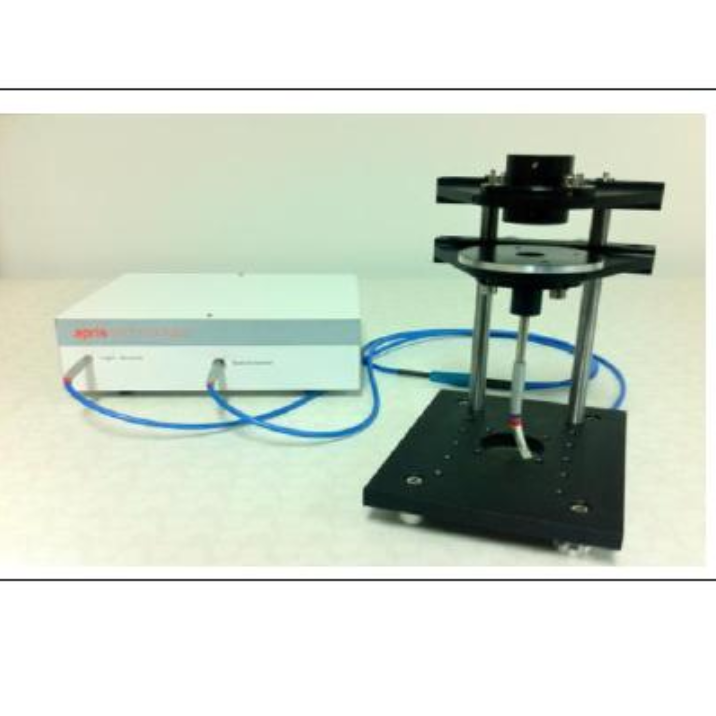

北京欧兰科技发展有限公司为您提供《雾沫中雾化形成在静电旋转钟镀膜中的应用检测方案(激光粒度仪)》,该方案主要用于其他中雾化形成在静电旋转钟镀膜中的应用检测,参考标准《暂无》,《雾沫中雾化形成在静电旋转钟镀膜中的应用检测方案(激光粒度仪)》用到的仪器有LaVision ParticleMaster-Shadow 粒径测量系统、Ekspla CARS 相干反斯托克斯拉曼显微光谱仪、Ekspla SFG 表面和频光谱分析系统。

我要纠错

相关方案

咨询

咨询