方案详情文

智能文字提取功能测试中

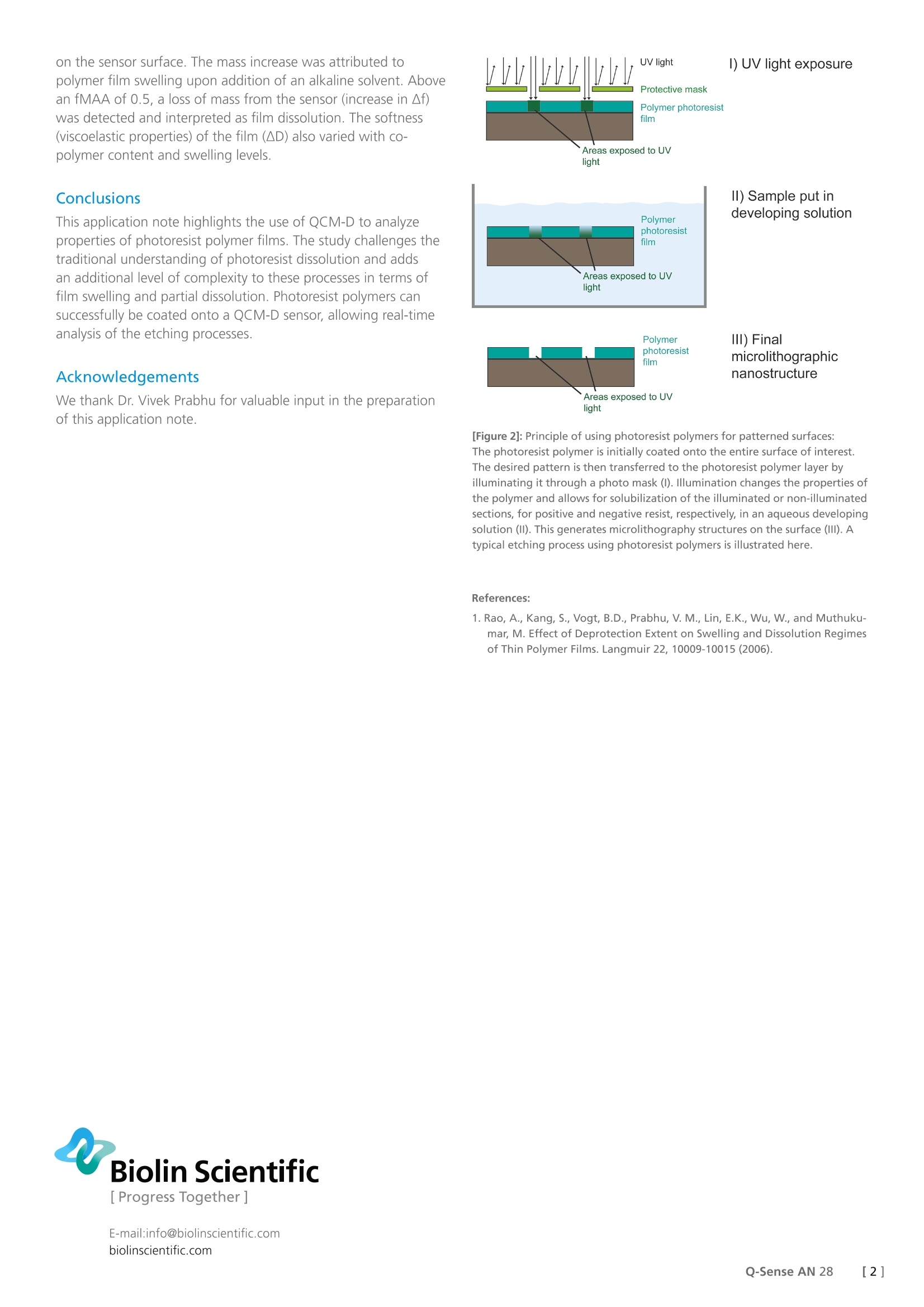

Biolin Scientific[ Progress Together] [Application Note] 28 QCM-D to study photoresist dissolution Photoresist polymers are commonly used in industrial processes such as micro-electronics and etching. They are light sensitive and are used where a patternedsurface coating is desired. This study uses QCM-D to analyze properties ofphotoresist polymer films. Introduction Many newly developed photoresist polymers swell when exposedto the developing solution, which is used when creating alithographic structure with photoresist polymers. For thesepolymers, the effects on the rate of dissolution due to theswelling process are poorly understood. The study reported inthis application note explores the response of a thin film to anaqueous alkaline solution as a function of the composition ofthe polymer as it changes. The study was conducted in real timeusing Quartz Crystal Microbalance with Dissipation monitoring(QCM-D). The reported data challenges the current models ofphotoresist polymer film dissolution mechanisms that do not takeinto account the swelling properties of the film. Experimental Q-Sense silicon oxide (QSX 303) or chromium (QSX 315) sensorswere subjected to silanization and then spin-coated with thephotoresist polymer to 120 nm thickness. The polymer-coatedsensors were then subjected to UV light to generate a photo acidcatalyzed deprotection reaction, see schematic in Figure 2. Thisreaction transforms the hydrophobic polymer into a hydrophilicco-polymer matrix. The amount of co-polymer (abbreviated MAA)formed could hence be controlled, generating several differentsensor surfaces with different fractions of co-polymer (fMAA). To gain insight into how the different polymer coatings respondto the alkaline aqueous solution used in the development stage,the coated sensors were placed in a Q-Sense E4 measurementchamber and a tetramethylammonium hydroxide (TMAH) solutionwas injected. The mass change, uptake via film swelling, or releasevia film dissolution, was quantified from the change in frequency(Af) and the change in dissipation (AD). Results and discussion Injection of the TMAH solution onto the sensors with differentco-polymer compositions yielded varied responses in the QCM-Dmeasurements. When the amount of co-polymer (fMAA)exceeded 0.3, an increase in mass (decrease in △f) was observed Co-polymer composition (fraction MAA) Green dots: dissolved polymers Light blue: water-rich, swollen polymers [Figure 1a and b]: illustrates the mass and viscoelastic changes with varyingco-polymer composition upon TMAH injection. From these QCM-D data incombination with FTIR spectroscopy, the authors were able to identify fourdifferent regimes of how the thin film responded to the developing solution:(I) no swelling, (II) film swelling only, (III) swelling and partial film dissolution,and (IV) nearly complete film dissolution. The different regimes wereattributed to local chemical heterogeneity of the polymer films. One reason forthe observed chemical heterogeneity is that during the deprotection reactionan increased number of hydrophilic domains within the film are produced,leading to different surface morphologies.These hydrophilic nano-scalestructures determine the degree of possible swelling and dissolution. Pleasenote that the lines are only to guide the eye. on the sensor surface.The mass increase was attributed topolymer film swelling upon addition of an alkaline solvent. Abovean fMAA of 0.5, a loss of mass from the sensor (increase in △f)was detected and interpreted as film dissolution. The softness(viscoelastic properties) of the film (△D) also varied with co-polymer content and swelling levels. Conclusions This application note highlights the use of QCM-D to analyzeproperties of photoresist polymer films. The study challenges thetraditional understanding of photoresist dissolution and addsan additional level of complexity to these processes in terms offilm swelling and partial dissolution. Photoresist polymers cansuccessfully be coated onto a QCM-D sensor, allowing real-timeanalysis of the etching processes. We thank Dr. Vivek Prabhu for valuable input in the preparationof this application note. [Figure 2]: Principle of using photoresist polymers for patterned surfaces:The photoresist polymer is initially coated onto the entire surface of interest.The desired pattern is then transferred to the photoresist polymer layer byilluminating it through a photo mask (l). Illumination changes the properties ofthe polymer and allows for solubilization of the illuminated or non-illuminatedsections, for positive and negative resist, respectively, in an aqueous developingsolution (II). This generates microlithography structures on the surface (II). Atypical etching process using photoresist polymers is illustrated here. References: 1. Rao, A., Kang, S., Vogt, B.D., Prabhu, V.M., Lin, E.K., Wu, W., and Muthuku-mar, M. Effect of Deprotection Extent on Swelling and Dissolution Regimesof Thin Polymer Films. Langmuir 22, 10009-10015 (2006). []Q-Sense AN Biolin Scientific[]Q-Sense AN

关闭-

1/2

-

2/2

产品配置单

瑞典百欧林科技有限公司为您提供《QCM-D研究光刻蚀分解》,该方案主要用于其它中null检测,参考标准《暂无》,《QCM-D研究光刻蚀分解》用到的仪器有QSense卓越版四通道石英晶体微天平、QSense Explorer扩展版石英晶体微天平、QSense全自动八通道石英晶体微天平。

我要纠错

相关方案

咨询

咨询