方案详情文

智能文字提取功能测试中

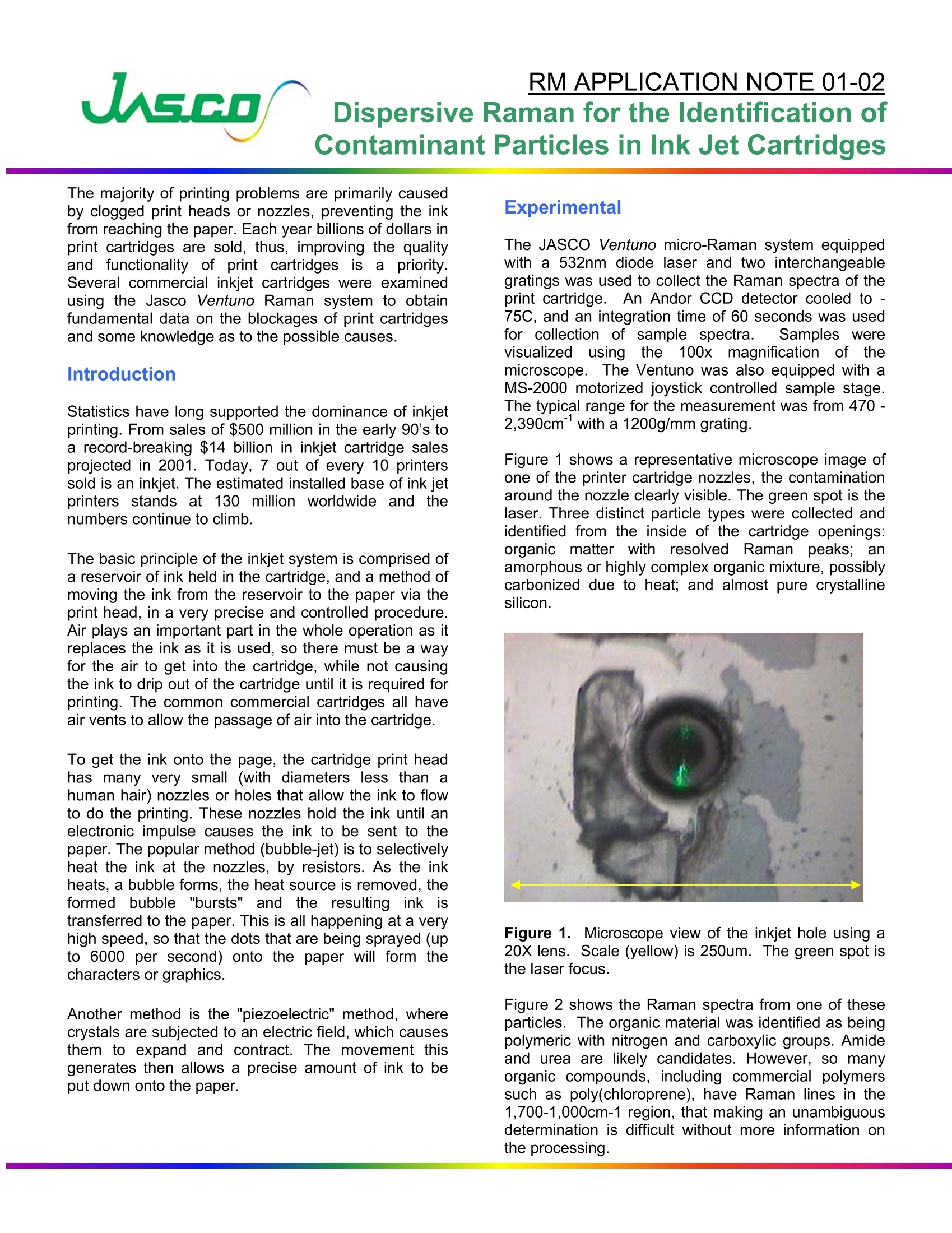

RM APPLICATION NOTE 01-02Dispersive Raman for the Identification ofContaminant Particles in Ink Jet CartridgesJasco,Inc.8649 Commerce Dr. Easton, MD 21601800-333-5272! Fax: 410-822-7526www.jascoinc.com The majority of printing problems are primarily causedby clogged print heads or nozzles, preventing the inkfrom reaching the paper. Each year billions of dollars inprint cartridges are sold, thus, improving the qualityand functionality of print cartridgessis apriority.Several commercial inkjet cartridges were examinedusing the Jasco Ventuno Raman system to obtainfundamental data on the blockages of print cartridgesand some knowledge as to the possible causes. Introduction Statistics have long supported the dominance of inkjetprinting. From sales of $500 million in the early 90's toa record-breaking $14 billion in inkjet cartridge salesprojected in 2001. Today, 7 out of every 10 printerssold is an inkjet. The estimated installed base of ink jetprinters stands at '130 million worldwide and thenumbers continue to climb. The basic principle of the inkjet system is comprised ofa reservoir of ink held in the cartridge, and a method ofmoving the ink from the reservoir to the paper via theprint head, in a very precise and controlled procedure.Air plays an important part in the wholeoperation as itreplaces the ink as it is used, so there must be a wayfor the air to get into the cartridge, while not causingthe ink to drip out of the cartridge until it is required forprinting. The common commercial cartridges all haveair vents to allow the passage of air into the cartridge. To get the ink onto the page, the cartridge print headhas many very small (with diameters less than ahuman hair) nozzles or holes that allow the ink to flowto do the printing. These nozzles hold the ink until anelectronic impulse causes the ink to be sent to thepaper. The popular method (bubble-jet) is to selectivelyheat the ink at the nozzles, by resistors. As the inkheats, a bubble forms, the heat source is removed, theformed bubblee"bursts" and the resulting inkistransferred to the paper. This is all happening at a veryhigh speed, so that the dots that are being sprayed (upto 6000 per second) onto the paper will form thecharacters or graphics. Another method is the "piezoelectric" method, wherecrystals are subjected to an electric field, which causesthem to expand and contract. The movement thisgenerates then allows a precise amount of ink to beput down onto the paper. The JASCO Ventuno micro-Raman system equippedwith a 532nm diode laser and two interchangeablegratings was used to collect the Raman spectra of theprint cartridge. An Andor CCD detector cooled to -75C, and an integration time of 60 seconds was usedfor collection of sample spectra. SSamples werevisualizedusingthe100xmagnification ofthemicroscope. The Ventuno was also equipped with aMS-2000 motorized joystick controlled sample stage.The typical range for the measurement was from 470 -2,390cmwith a 1200g/mm grating. Figure 1 shows a representative microscope image ofone of the printer cartridge nozzles, the contaminationaround the nozzle clearly visible. The green spot is thelaser. Three distinct particle types were collected andidentified from the inside of the cartridge openings:organic matter with resolved Raman peaks; anamorphous or highly complex organic mixture, possiblycarbonized due to heat; and almost pure crystallinesilicon. Figure 1. Microscope view of the inkjet hole using a20X lens. Scale (yellow) is 250um. The green spot isthe laser focus. Figure 2 shows the Raman spectra from one of theseparticles. The organic material was identified as beingpolymeric with nitrogen and carboxylic groups. Amideand urea are likely candidates. However, so manyorganic compounds, including commercial polymerssuch as poly(chloroprene), have Raman lines in the1,700-1,000cm-1 region, that making an unambiguousdetermination is difficult without more information onthe processing. Figure 2. Raman spectrum from 475-2390cm° of atypical organic particle in the cartridge opening. A representative microscope image of a silicon particlefound in the cartridge opening is shown in Figure 3.The 2 micron green laser spot highlights the particlewhich is not much bigger than the laser spot.. TheRaman spectrum of the particle is shown in Figure 4.The first and second order peaks used to identify thesilicon particle are labeled. Silicon is sometimes usedin inkjets and this is a likely origin of the small siliconparticles. Figure 3.. ,20M microscope image of a silica particlefound in the opening. Scale (yellow) is 50um. Figure 4. FRaman spectrum from 470-2375cm°of atypical silica particle found in the cartridge opening. One of the major problems faced with refilling inkcartridges is the clogging of ink jets. Many black inkcartridges contain pigmented ink. Pigmented ink is notwater soluble (like dye based inks) often contain solidmicroscopic particles of a carbon-polymer compound.The pigmented ink that remains in a cartridge forms apaste that eventually hardens and strongly adheres tothe inside of the cartridge. Every printer cartridgeopening that was examined contained some type ofparticulate matter. Most of these contaminant particleswere in the micron size range. Identification of thecompounds that create the blockages can lead to theirelimination and make ink cartridges less susceptible toclogs. Conclusions The Raman spectra and representative microscopeimages wereused 1to) characterizethenozzlecontaminants. Preliminary peak assignments for someof the organic materials were suggested and the siliconparticles positively identified. Examinationn of thecompounds that create the blockages may providedata to improve the inkjet printing mechanism andenhance the development of inkjet cartridges that areless susceptible to theclogging that plagues mostsystems. Contact: The majority of printing problems are primarily causedby clogged print heads or nozzles, preventing the inkfrom reaching the paper. Each year billions

关闭-

1/2

-

2/2

产品配置单

佳士科商贸有限公司为您提供《喷墨墨盒中污染粒子检测方案 》,该方案主要用于油墨中污染粒子检测,参考标准《暂无》,《喷墨墨盒中污染粒子检测方案 》用到的仪器有JASCONRS5000/7000共聚焦激光拉曼光谱仪、JASCORMP-500便携激光拉曼分光光度计、jascoRFT-6000傅立叶变换红外拉曼光谱仪。

我要纠错

相关方案

咨询

咨询