方案详情文

智能文字提取功能测试中

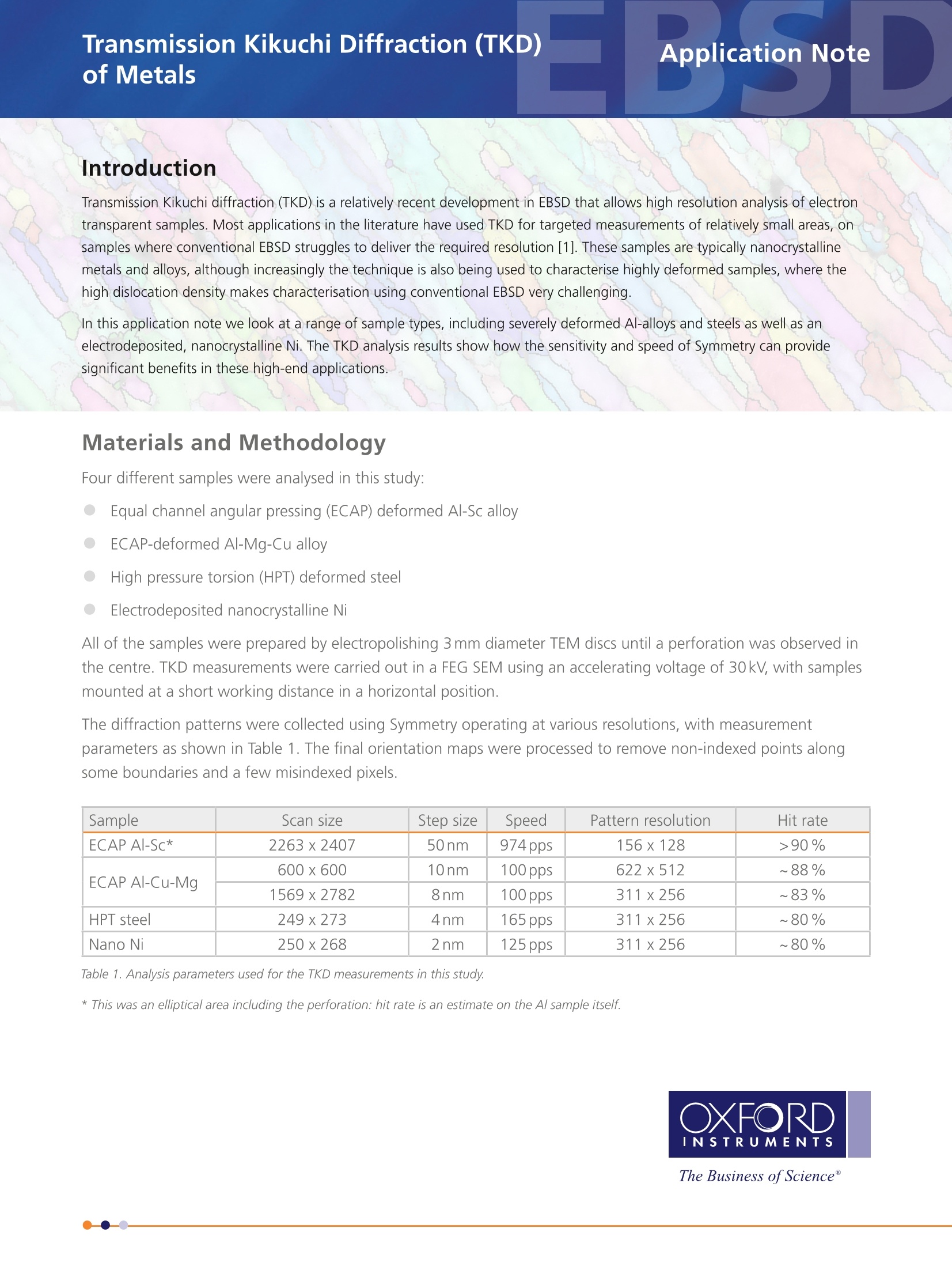

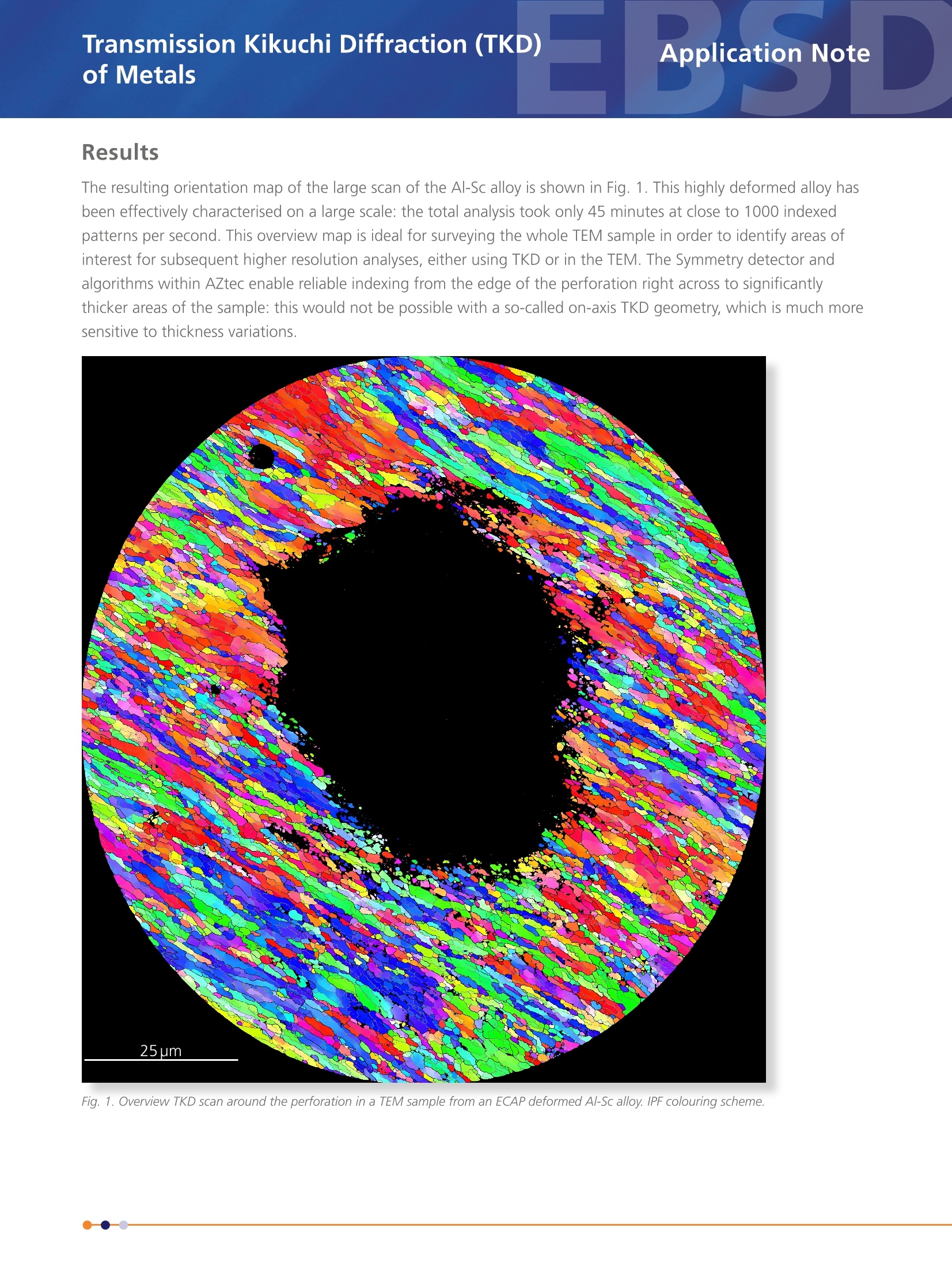

Application Note Transmission Kikuchi Diffraction (TKD)of Metals Introduction Transmission Kikuchi diffraction (TKD) is a relatively recent development in EBSD that allows high resolution analysis of electrontransparent samples. Most applications in the literature have used TKD for targeted measurements of relatively small areas, onsamples where conventional EBSD struggles to deliver the required resolution [1]. These samples are typically nanocrystallinemetals and alloys, although increasingly the technique is also being used to characterise highly deformed samples, where thehigh dislocation density makes characterisation using conventional EBSD very challenging. In this application note we look at a range of sample types, including severely deformed Al-alloys and steels as well as anelectrodeposited, nanocrystalline Ni. The TKD analysis results show how the sensitivity and speed of Symmetry can providesignificant benefits in these high-end applications. Materials and Methodology Four different samples were analysed in this study: Equal channel angular pressing (ECAP) deformed Al-Sc alloy ECAP-deformed Al-Mg-Cu alloy High pressure torsion (HPT) deformed steel Electrodeposited nanocrystalline Ni All of the samples were prepared by electropolishing 3mm diameter TEM discs until a perforation was observed inthe centre. TKD measurements were carried out in a FEG SEM using an accelerating voltage of 30kV, with samplesmounted at a short working distance in a horizontal position. The diffraction patterns were collected using Symmetry operating at various resolutions, with measurementparameters as shown in Table 1. The final orientation maps were processed to remove non-indexed points alongsome boundaries and a few misindexed pixels. Sample Scan size Step size Speed Pattern resolution Hit rate ECAP AI-Sc* 2263x2407 50nm 974pps 156x128 >90% ECAP AI-Cu-Mg 600x600 10nm 100 pps 622x512 ~88% 1569x2782 8nm 100 pps 311x256 ~83% HPT steel 249x273 4nm 165 pps 311x256 ~80% Nano Ni 250x268 2nm 125pps 311x256 ~80% Table 1. Analysis parameters used for the TKD measurements in this study. * This was an elliptical area including the perforation: hit rate is an estimate on the Al sample itself. The Business ofScience@ Transmission Kikuchi Diffraction (TKD)of Metals Results The resulting orientation map of the large scan of the Al-Sc alloy is shown in Fig. 1.This highly deformed alloy hasbeen effectively characterised on a large scale: the total analysis took only 45 minutes at close to 1000 indexedpatterns per second. This overview map is ideal for surveying the whole TEM sample in order to identify areas ofinterest for subsequent higher resolution analyses, either using TKD or in the TEM. The Symmetry detector andalgorithms within AZtec enable reliable indexing from the edge of the perforation right across to significantlythicker areas of the sample: this would not be possible with a so-called on-axis TKD geometry, which is much moresensitive to thickness variations. Fig. 1. Overview TKD scan around the perforation in a TEM sample from an ECAP deformed Al-Sc alloy. IPF colouring scheme. Transmission Kikuchi Diffraction (TKD)of Metals In the second deformed Al-alloy, the ECAP deformation has resulted in ultrafine-grained shear bands that areimpossible to analyse effectively using conventional EBSD. A 6 x6 um area within one such shear band was scannedin approximately one hour, and the final pattern quality and orientation maps are shown in figure 2. The presenceof many nanostructured grains, under 100 nm diameter, is clear but there are also numerous elongate grainsseveral um long. These are highly substructured, with numerous low angle boundaries and regions of more diffuselocal misorientation. Even so, the mean grain diameter in this area is 170±5 nm. The second, larger analysis on this sample examined the edge of one of the shear bands (Fig. 3): here the grainsize refinement had not continued to the same extent as shown in Fig. 2, with many more elongate, larger grainsremaining. The results show how larger area TKD analyses are often required in order to characterise effectivelyheterogeneous microstructures such as in this alloy. Fig. 2a. Pattern quality map of an ECAP deformed AI-Mg-Cu alloy. Fig. 2b. Orientation map of the same area, with high angleboundaries in black, low angle boundaries in grey. Application Note Transmission Kikuchi Diffraction (TKD)of Metals The steel sample, deformed at room temperature using HPT, has a more nanostructured microstructure, as shownin Fig. 4. The mean grain diameter here is 51±2 nm, and it can be seen that the TKD analysis has resolved all butthe very finest grained regions. In addition to the nanostructured grain size, many of the grains in this samplecontain significant densities of geometrically necessary dislocations (in the 1016m²range), resulting in orientationchanges exceeding 10° across 100 nm transects. There are also a few grains that contain 23 twin boundaries(red lines in figure 4b), an interesting observation in a ferritic sample. The ability of Symmetry to collect EBSPsquickly and with good resolution (in this case 311x256 pixels at 165 pps) has enabled an effective and quickcharacterisation of this very challenging microstructure. Fig. 4a. Pattern quality map of an HPT-deformed steel sample. Fig. 4b. Orientation map (IPF colouring) of the same area, with highangle boundaries in black, low angle boundaries in grey and 23 twinboundaries in red. The final sample analysed in this study is an example of a bottom-up approach to forming nanocrystalline material.Rather than refining an originally coarse grained material using severe plastic deformation, this sample has beenelectrodeposited with a nanocrystalline structure from the start. The challenge for analysis here is the exceptionallyfine grain size - significantly less than 50nm. The pattern quality and grain size maps shown in Fig. 5 illustrate thatTKD, with a measurement step size of 2 nm, is able to characterise effectively this nanostructured sample. Manyof the grains contain 23 twin boundaries (shown in red in Fig. 5b) but even disregarding these boundaries, themajority of grains have a diameter under 50nm and many are less than 20 nm (blue in Fig.5b). The mean grain sizeof this sample is 20.8±0.5 nm, based on more than 500 measured grains. Fig. 5a. Pattern quality map of a nanocrystalline Ni sample. Fig. 5b. Grain size map of the same area. Note that blue grains havea diameter under 20nm. Twin boundaries (red lines) have beenexcluded from the grain size measurement. Conclusion The results shown in this report give a clear indication of the power of the CMOS-based Symmetry EBSD detectorfor effective analysis of nanostructured and severely deformed materials using TKD. The ability to collect goodresolution diffraction patterns at high speed, and the sensitivity to optimise the SEM beam conditions withouthaving to compromise on acquisition rates, makes Symmetry the ideal detector for TKD analyses. In addition, adjusting the phosphor screen elevation using Symmetry's variable tilting mechanism allows users toensure that the sample and detector are always in the perfect geometry for high resolution TKD analyses. Theseresults illustrate how superfast TKD provides a rapid, detailed overview of whole TEM samples and how, withoptimum beam conditions, TKD can be used to characterise samples with a mean grain size as small as 20 nm. Reference 1. Sneddon et al. (2016). Materials Science and Engineering: R: Reports. 110, p 1-12. Acknowledgments Oxford Instruments thanks Katja Eder and Adam Sikorski (Australian Centre for Microscopy & Microanalysis) for providing the Al-Sc alloyand assisting with TEM sample preparation. www.oxford-instruments.com/symmetry Transmission Kikuchi diffraction (TKD) is a relatively recent development in EBSD that allows high resolution analysis of electrontransparent samples. Most applications in the literature have used TKD for targeted measurements of relatively small areas, onsamples where conventional EBSD struggles to deliver the required resolution [1]. These samples are typically nanocrystallinemetals and alloys, although increasingly the technique is also being used to characterise highly.

关闭-

1/6

-

2/6

还剩4页未读,是否继续阅读?

继续免费阅读全文产品配置单

牛津仪器科技(上海)有限公司为您提供《纳米晶金属和合金中表征检测方案(EBSD系统)》,该方案主要用于其他中理化分析检测,参考标准《暂无》,《纳米晶金属和合金中表征检测方案(EBSD系统)》用到的仪器有牛津仪器C-Swift EBSD探测器。

我要纠错

推荐专场

电子背散射衍射系统(EBSD)

更多相关方案

咨询

咨询