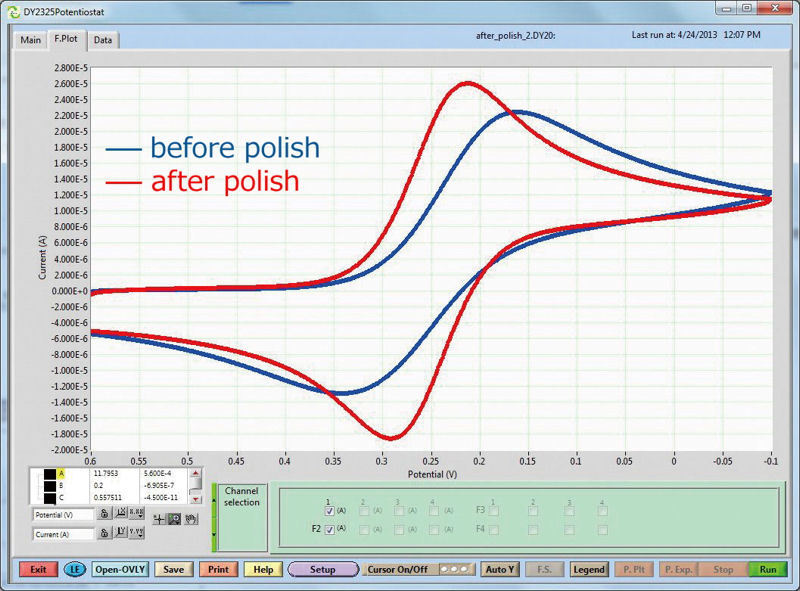

重复的电化学氧化还原反应的实验,实验的产品上粘附到电极表面的电子转移速率,并逐渐衰减。如果电子转移速度变慢,对氧化还原峰电位差将拓宽之间。

清爽的电极表面通过抛光,电子转移速率将再次提高。因此,峰电位差变窄,返回到一个理想的简历。

电极:玻碳电极

| Catalogue No. | Description |

| 013223 | PK-3 Electrode Polishing kit |

| Contents | |

| 012620 | 0.05 µm polishing alumina (20 ml) |

| 012621 | 1 µm polishing diamond (10 ml) |

| - | Alumina polishing pad (10 pcs) |

| - | Diamond polishing pad (10 pcs) |

| 013222 | Replacement glass plate for PK-3 (1 pc) |

| Polishing pad for acquisition separately | |

| 012600 | Alumina polishing pad (20 pcs) |

| 012601 | Diamond polishing pad (20 pcs) |

How to polish the Working electrodes' surface with PK-3

- Prepare the glass plate, and put a few drops of polishing diamond on diamond polishing pad.

- Hold the CV electrode at right angle to the pad, and polish in a circular motion.

- Replace the diamond pad to an alumina polishing pad, put a few drops of polishing alumina, and polish the electrode to be mirror surface. Rinse the electrode surface with distilled water, and finish by air drying.

Polishing of PFCE Electrode & Pyrolytic Graphite Electrode

For the electrodes listed below,| Catalog No. | Description | Isolation | OD | ID |

| 002252 | Pyrolytic Graphite Electrode (Basal Plane) | PEEK | 6 mm | 3 mm |

| 002253 | Pyrolytic Graphite Electrode (Edge Plane) | PEEK | 6 mm | 3 mm |

| 002408 | PFCE 3 Carbon electrode | PEEK | 6 mm | 3 mm |

| 002409 | PFCE 1 Carbon electrode | PEEK | 6 mm | 1 mm |

| 011854 | SPFCE Carbon electrode | PEEK | 3 mm | 1 mm |

It is recommended the follow polishing step:

- Put a few drops of distilled water on the emery paper, and polish for 10 seconds. If necessary increase the polishing time.

- Then rinse the electrode with distilled water.

-

After rinse, ultrasonic cleaning for 10 seconds (in the case of 65 W - 100 W ultrasonic cleaner).

Or polishing the electrode using alumina pad with a few drops of distilled water for about 10 seconds. - Then rinse the electrode again with a distilled water.

- Dry the electrode and it is ready for the measurement.

电极打磨工具包信息由海蓝嘉胜科技(北京) 有限公司为您提供,如您想了解更多关于电极打磨工具包报价、型号、参数等信息,欢迎来电或留言咨询。

相关产品

仪器对比

仪器对比

关注

关注