方案详情文

智能文字提取功能测试中

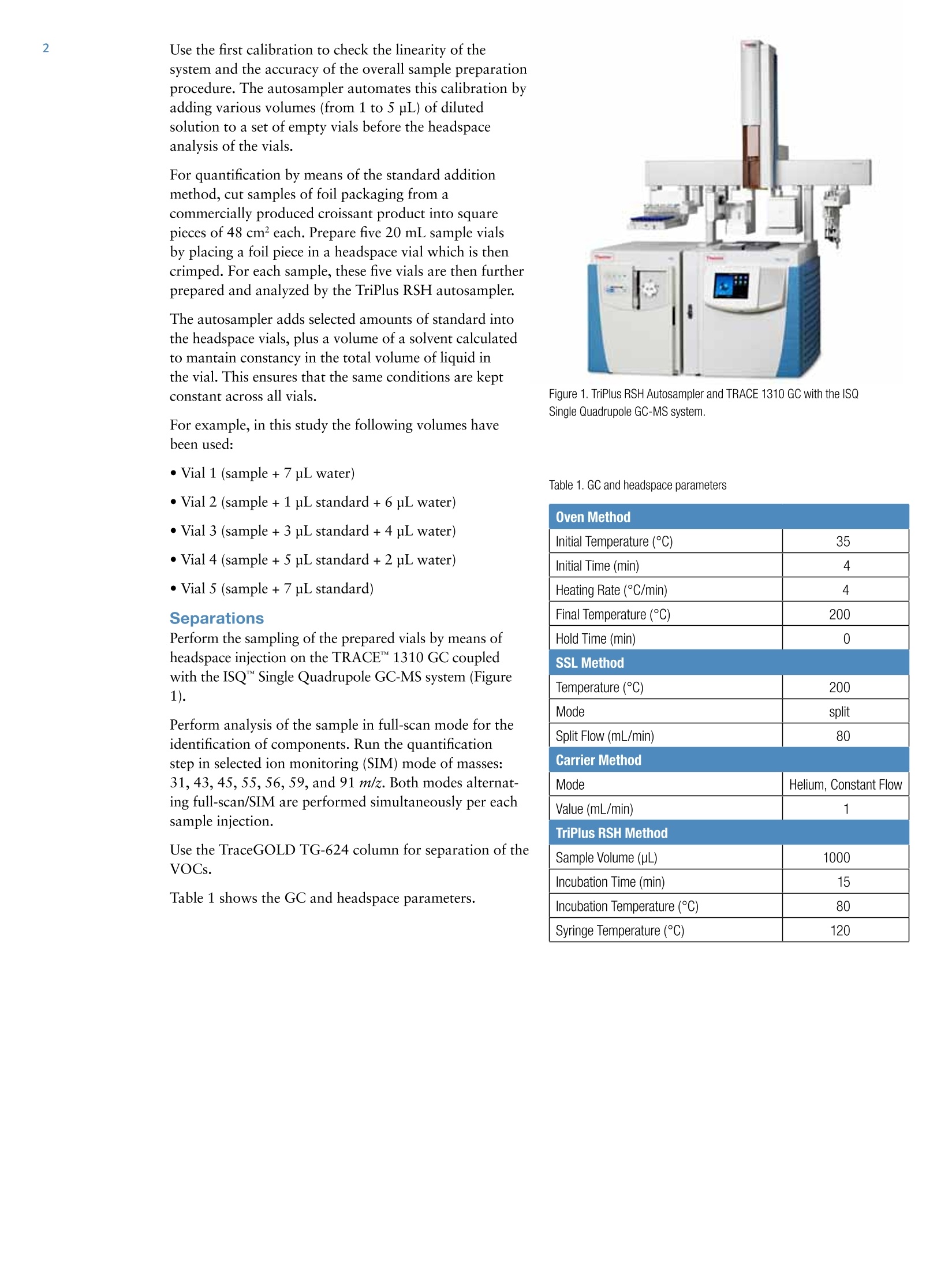

2 4 Unattended Automated StandardAddition and Headspace Analysisfor the Quantitative Determinationof VOCs in Food Packaging Stefano Pelagatti, Silvia Gemme, Andrea Caruso,Fausto Pigozzo, Massimo Santoro, and Eric Phillips?Thermo Fisher Scientific, Milan, Italy; 2Thermo Fisher Scientific, Austin, Texas, USA TRACE 1310 GC, ISQ GC-MS, TriPlus RSH, Volatile Organic Compounds in Food Packaging To demonstrate fully automated quantitative determinationof volatile components in food packaging Introduction Headspace analysis by means of a dedicated autosampleris a standard technique for the determination of volatileorganic compounds (VOCs) possibly present in foodpackaging materials. The packaging sample is typicallycut into square pieces and placed in headspace vialsfor incubation at a determined temperature before theheadspace sampling. The main challenge with this kind ofanalysis is the quantification of volatile compounds that arepresent because these samples are typically layered solidsthat generate adsorption and migration effects. Externalcalibration is not reliable because it does not consider thematrix effect, which is significant for these samples. In contrast, the standard addition calibration is a reasonablequantification procedure for these difficult matrixes becauseit uses real sample for the calibration procedure. Until now,preparation of samples for the standard addition calibrationhas been performed off-line, typically executed manuallyby the operator before headspace analysis of the samples.This is a time-consuming and error-prone procedure, whileperforming sample preparation by means of the samerobotic sampler used for headspace analysis enables thequantification sequence to be run automatically in anunattended way. Detection and quantification are performedby means of a gas chromatograph (GC) coupled with asingle quadrupole mass spectrometer (MS). Materials and Methods Use the Thermo Scientific TRACE 1310 GC, coupled withthe ISQ Single Quadrupole GC-MS, for analysis of thesamples. Configure the GC with an instant connect split/splitless (SSL) module, operated in split mode. The headspace incubation temperature is 80 ℃ and theincubation time is 15 min. The headspace injected volumeis 1 mL. Use the Thermo Scientific TraceGOLD TG-624GC Column (1.4 um film thickness; 0.25mm ID;60mlength). The VOCs standards solution is: · Residual Solvents in Packaging Material Mixture 1,analytical standard, 7.14% (v/v) (Sigma-Aldrich) ·Residual Solvents in Packaging Material Mixture 2,analytical standard, 9.09% (v/v) (Sigma-Aldrich) Mix to obtain a single comprehensive stock solution. Automatically perform subsequent sample preparationand injection steps using the Thermo Scientific TriPlusRSH Autosampler. The tool exchange capability andvortex mixing allow the dilution step, the standardaddition step, and the headspace analysis step to becombined together in the same sequence. Procedures Automatic Standard Dilution Procedure The stock solution is first automatically diluted 1/1000with water by the TriPlusTM RSH autosampler. In thiscycle, the autosampler takes the necessary aliquot ofwater and places it in an empty vial, adding the amount ofstock solution to bring to final volume (in this case, 1 ml)using a different volume syringe. The diluted solution obtained contains all the componentsin a concentration range of 0.035-0.045 ug/uL that issuitable for the determination of low levels of residualsolvent in packaging material. Use the first calibration to check the linearity of thesystem and the accuracy of the overall sample preparationprocedure. The autosampler automates this calibration byadding various volumes (from 1 to 5 pL) of dilutedsolution to a set of empty vials before the headspaceanalysis of the vials. For quantification by means of the standard additionmethod, cut samples of foil packaging from acommercially produced croissant product into squarepieces of 48 cm’each. Prepare five 20 mL sample vialsby placing a foil piece in a headspace vial which is thencrimped. For each sample, these five vials are then furtherprepared and analyzed by the TriPlus RSH autosampler. The autosampler adds selected amounts of standard intothe headspace vials, plus a volume of a solvent calculatedto mantain constancy in the total volume of liquid inthe vial. This ensures that the same conditions are keptconstant across all vials. For example, in this study the following volumes havebeen used: ·Vial 1 (sample +7 pL water) · Vial 2(sample+1pL standard +6 pL water) · Vial 3 (sample +3 pL standard + 4 pL water) ·Vial 4 (sample+ 5 pL standard +2 pL water) · Vial 5 (sample + 7 pL standard) Separations Perform the sampling of the prepared vials by means ofheadspace injection on the TRACE1310 GC coupledwith the ISQ" Single Quadrupole GC-MS system (Figure1). Perform analysis of the sample in full-scan mode for theidentification of components. Run the quantificationstep in selected ion monitoring (SIM) mode of masses:31, 43, 45,55,56,59, and 91 m/z. Both modes alternat-ing full-scan/SIM are performed simultaneously per eachsample injection. Use the TraceGOLD TG-624 column for separation of theVOCs. Table 1 shows the GC and headspace parameters. Figure 1. TriPlus RSH Autosampler and TRACE 1310 GC with the ISQSingle Quadrupole GC-MS system. Table 1. GC and headspace parameters Oven Method Initial Temperature (C) 35 Initial Time (min) 4 Heating Rate (°C/min) 4 Final Temperature (℃) 200 Hold Time (min) 0 SSL Method Temperature (C) 200 Mode split Split Flow (mL/min) 80 Carrier Method Mode Helium, Constant Flow Value (mL/min) 1 TriPlus RSH Method Sample Volume (pL) 1000 Incubation Time (min) 15 Incubation Temperature (C) 80 Syringe Temperature (°C) 120 Results and Discussion The results show good correlation factors and limits ofquantification <0.01 mg/m² for the majority of thecomponents analyzed. Linearity of Standard Addition Figure 2 reports the list of components and the overlay ofchromatograms obtained for each volume of standard(from 1 to 5 uL) added into empty vials. The linearity of the system and the limits of quantificationfor all components are derived by converting the data ofaddition volumes into an absolute amount expressed inmg/m²(assuming that the sample surface in the vial is48 cm²). The graphs in Figure 3 show good linearity ofthe system. Quantification limits below 0.01 mg/m² havebeen calculated for all compounds except THF, ethanol,and ethoxy ethanol. Sample Analysis (Components Identification) A full-scan chromatogram of the packaging samplewas performed in order to identify the componentspossibly present. Figure 4 shows the presence of numerous residualsolvents. The larger ethanol peak comes from thecroissant itself where ethanol is used as a preservative. Sample Analysis (Components Quantification) Quantification performed by means of the standardaddition method was carried out for the peaks identifiedin the chromatogram in Figure 4. Figure 5 shows thestandard addition calibration curve for n-butyl acetatetogether with the results of quantification in the sample. Table 2 presents the results of the quantification. In Figure 6, the graphical representation of thequantification analysis shows that the two mainresidual solvents identified in the sample are 1-methoxy2-propanol and 2-propanol. Their amounts do not exceedthe level of 0.1 mg/m² each, while the other detectedresidual solvents have been quantified in the level of 0.01mg/m’or lower. Conclusion A completely automated method for analyzing andquantifying VOCs in food packaging materials ispresented. The combination of sample preparation stepsand an analytical step in the same sequence allows highaccuracy in quantification, high sample throughput, andminimizes error-prone manual manipulations. For themajority of residual solvents analyzed in this method, theirindividual limit of quantitation was below 0.01 mg/m². Figure 4. Full-scan sample analysis by headspace. R2=0.9996 Figure 5. Quantitation via standard addition calibration for n-butyl acetate. Table 2. Quantification results from a real croissant packaging foil sample of 48 cm? area uL added Component 0 1 3 5 7 2-propanol 3337694 4162371 6363394 7060114 8101360 area 0 0.009469 0.028406 0.047344 0.066281 concentration mg/m² 5.02E-02 calculated amount mg/m? ethyl acetate 302671 973347 2755297 4304253 6115361 area 0 0.007438 0.022313 0.037188 0.052063 concentration mg/m² 2.00E-03 calculated amount mg/m² 1-butanol 385906 761497 1708139 2203362 3191062 area 0 0.007438 0.022313 0.037188 0.052063 concentration mg/m² 7.55E-03 calculated amount mg/m? 1-methoxy 2-propanol 3873000 4854145 5683277 6258900 7857878 area 0 0.009469 0.028406 0.047344 0.066281 concentration mg/m² 7.44E-02 calculated amount mg/m² 4-methyl 2-pentanone 374131 837187 1642593 2555176 3209676 area 0 0.009469 0.028406 0.047344 0.066281 concentration mg/m² 9.57E-03 calculated amount mg/m? toluene 1077304 1512873 2382486 2972530 3683690 area 0 0.007438 0.022313 0.037188 0.052063 concentration mg/m² 2.31E-02 calculated amount mg/m² n-butyl acetate 190875 649615 1751135 2741910 3859582 area 0 0.007438 0.022313 0.037188 0.052063 concentration mg/m² 2.26E-03 calculated amount mg/m² Figure 6. VOCs detected in croissant packaging and their relative distribution. www.thermoscientific.com ◎2012 Thermo Fisher Scientific Inc. All rights reserved. ISO is a trademark of the International Standards Organization.Sigma-Aldrich is a registered trademark of Sigma-Aldrich Co. LLC. All other trademarks are the property of Thermo FisherScientific Inc. and its subsidiaries. Specifications, terms and pricing are subject to change. Not all products are available irinall countries. Please consult your local sales representative for details. This information is presented as an example of thecapabilities of Thermo Fisher products. It is not intended to encourage use of these products in any manners that might infringethe intellectual property rights of others. 9001Thermo Fisher Scientific, Austin, TX USA is ISO Certified. wrJwo? 通过专用自动进样器的顶空分析是一种标准技术,适用于测定可能存在于食品包装材料中的挥发性有机化合物 (VOC)。

关闭-

1/5

-

2/5

还剩3页未读,是否继续阅读?

继续免费阅读全文产品配置单

赛默飞色谱与质谱为您提供《食品包装中VOC定量检测方案(气相色谱仪)》,该方案主要用于包装中VOC定量检测,参考标准《暂无》,《食品包装中VOC定量检测方案(气相色谱仪)》用到的仪器有赛默飞TRACE 1310 气相色谱仪、赛默飞ISQ™ 7000单四极杆GC-MS、赛默飞TriPlus RSH 气相/气质自动进样器。

我要纠错

推荐专场

气相色谱仪(GC)

更多相关方案

咨询

咨询