方案详情文

智能文字提取功能测试中

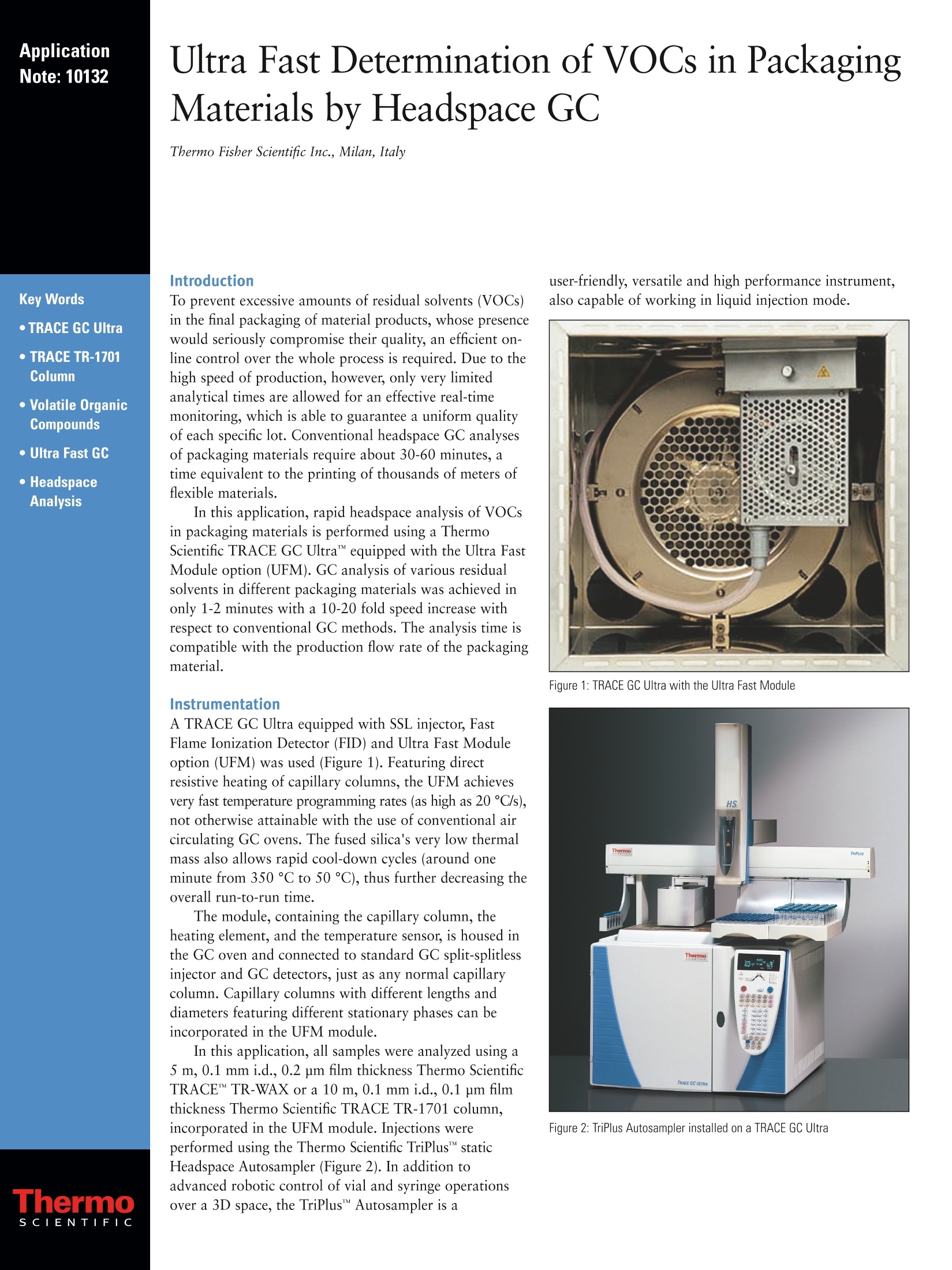

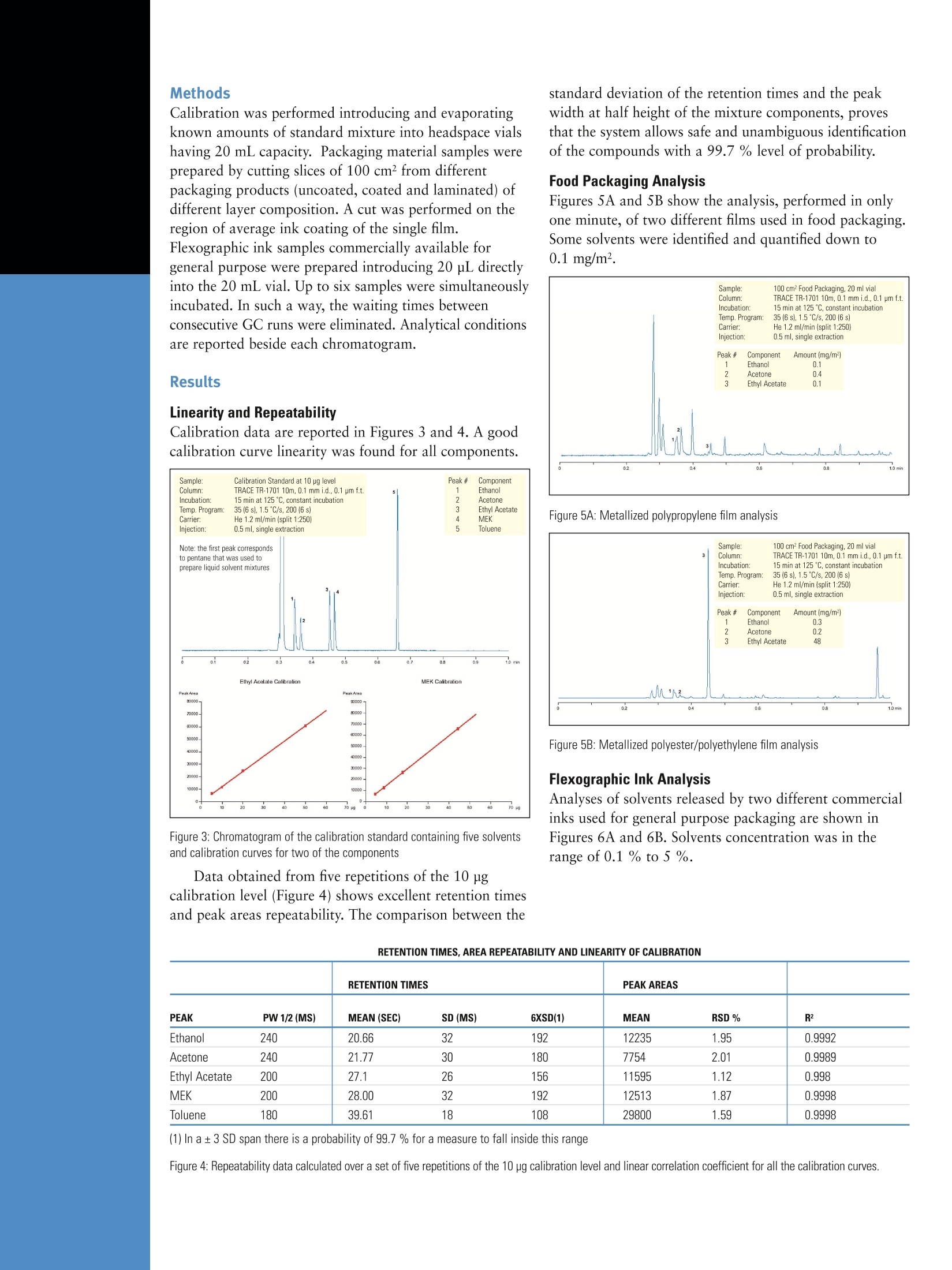

SCIENTIFICPart of Thermo Fisher Scientific Ultra Fast Determination of VOCs in PackagingMaterials by Headspace GC Thermo Fisher Scientific Inc., Milan, Italy Introduction To prevent excessive amounts of residual solvents (VOCs)in the final packaging of material products, whose presencewould seriously compromise their quality, an efficient on-line control over the whole process is required. Due to thehigh speed of production, however, only very limitedanalytical times are allowed for an effective real-timemonitoring, which is able to guarantee a uniform qualityof each specific lot. Conventional headspace GC analysesof packaging materials require about 30-60 minutes, a1time equivalent to the printing of thousands of meters offlexible materials. In this application, rapid headspace analysis of VOCsin packaging materials is performed using a ThermoScientific TRACE GC Ultra equipped with the Ultra FastModule option (UFM). GC analysis of various residualsolvents in different packaging materials was achieved inonly 1-2 minutes with a 10-20 fold speed increase withrespect to conventional GC methods. The analysis time iscompatible with the production flow rate of the packagingmaterial. Instrumentation A TRACE GC Ultra equipped with SSL injector, FastFlame Ionization Detector (FID) and Ultra Fast Moduleoption (UFM) was used (Figure 1). Featuring directresistive heating of capillary columns, the UFM achievesvery fast temperature programming rates (as high as 20 °C/s),not otherwise attainable with the use of conventional aircirculating GC ovens. The fused silica’s very low thermalmass also allows rapid cool-down cycles (around oneminute from 350 °C to 50 ℃), thus further decreasing theoverall run-to-run time. The module, containing the capillary column, theheating element, and the temperature sensor, is housed inthe GC oven and connected to standard GC split-splitlessinjector and GC detectors, just as any normal capillarycolumn. Capillary columns with different lengths anddiameters featuring different stationary phases can beincorporated in the UFM module. In this application, all samples were analyzed using a5 m, 0.1 mm i.d., 0.2 um film thickness Thermo ScientificTRACE"TR-WAX or a 10 m, 0.1 mm i.d., 0.1 um filmthickness Thermo Scientific TRACE TR-1701 column,incorporated in the UFM module. Injections wereperformed using the Thermo Scientific TriPlus" staticHeadspace Autosampler (Figure 2). In addition toadvanced robotic control of vial and syringe operationsover a 3D space, the TriPlus" Autosampler is a user-friendly, versatile and high performance instrument,also capable of working in liquid injection mode. Figure 1: TRACE GC Ultra with the Ultra Fast Module Calibration was performed introducing and evaporatingknown amounts of standard mixture into headspace vialshaving 20 mL capacity. Packaging material samples wereprepared by cutting slices of 100 cm² from differentpackaging products (uncoated, coated and laminated) ofdifferent layer composition. A cut was performed on theregion of average ink coating of the single film.Flexographic ink samples commercially available forgeneral purpose were prepared introducing 20 pL directlyinto the 20 mL vial. Up to six samples were simultaneouslyincubated. In such a way, the waiting times betweenconsecutive GC runs were eliminated. Analytical conditionsare reported beside each chromatogram. Results Linearity and Repeatability Calibration data are reported in Figures 3 and 4. A goodcalibration curve linearity was found for all components. Figure 3: Chromatogram of the calibration standard containing five solventsand calibration curves for two of the components Data obtained from five repetitions of the 10 ugcalibration level (Figure 4) shows excellent retention timesand peak areas repeatability. The comparison between the standard deviation of the retention times and the peakwidth at half height of the mixture components, provesthat the system allows safe and unambiguous identificationof the compounds with a 99.7 % level of probability. Food Packaging Analysis Figures 5A and 5B show the analysis, performed in onlyone minute, of two different films used in food packaging.Some solvents were identified and quantified down to0.1 mg/m². Figure 5A: Metallized polypropylene film analysis Figure 5B: Metallized polyester/polyethylene film analysis Flexographic Ink Analysis Analyses of solvents released by two different commercialinks used for general purpose packaging are shown inFigures 6A and 6B. Solvents concentration was in therange of 0.1 % to 5 %. RETENTION TIMES, AREA REPEATABILITY AND LINEARITY OF CALIBRATION RETENTION TIMES PEAK AREAS PEAK PW 1/2 (MS) MEAN (SEC) SD (MS) 6XSD(1) MEAN RSD % R2 Ethanol 240 20.66 32 192 12235 1.95 0.9992 Acetone 240 21.77 30 180 7754 2.01 0.9989 Ethyl Acetate 200 27.1 26 156 11595 1.12 0.998 MEK 200 28.00 32 192 12513 1.87 0.9998 Toluene 180 39.61 18 108 29800 1.59 0.9998 . (1) In a±3 SD span there is a probability of 99.7 % for a measure to fall inside this range In addition to theseoffices, Thermo FisherScientific maintainsa network of represen-tative organizationsthroughout the world. Australia Figure 6A: Sample 1-Red ink analysis +61 2 88449500 Austria +431 333 50340 Belgium +322 482 30 30 Canada +1 800 532 4752 China +86 10 58503588 Denmark +45 70 23 6260 France +33 1 60 92 48 00 Germany +49 61034081014 India +91226742 9434 Italy +39 02 950 591 Figure 6B: Sample 2 - Red ink analysis Japan +81 45 453 9100 Latin America Conclusions +1 608 276 5659 Rapid Headspace analysis of residual solvents (VOCs) inpackaging materials can successfully be performed withhigh precision and accuracy, using the TRACE GC Ultraequipped with the Ultra Fast GC option. The combinationof the Ultra Fast GC technique with TriPlus HS Autosampler,featuring optimization of the incubation times, allows theanalyst to achieve a total analysis cycle time of about fiveminutes per sample, in line with the requirements of aproduction flow rate of packaging materials. Netherlands +31 76 587 98 88 South Africa +2711 570 1840 Spain +34916574930 Sweden/Norway/ Finland +46 855646800 Switzerland +41614878400 UK +44 1442 233555 References USA +1 800 5324752 [1] P. Magni, R. Facchetti, D. Cavagnino and S. Trestianu, Proceedings of 25thInternational Symposium of Capillary Chromatography, KNL05, Riva delGarda, Italy, May 13-17, 2002, ed. P. Sandra. www.thermo.com [2] F. Munari, S. Pelagatti and P. Mapelli, Enhanced Performances in Liquidand Gas Injections in Capillary GC through a Robotic, Versatile Autosampler,I11, Riva del Garda, Italy, May 31-June 04, 2004, ed. P. Sandra. ISO 9001 DNV-CERT-00203-94-AQ Thermo Electron Italia S.p.A is ISO certified. Authors: Riccardo Facchetti, Andrea Cadoppi O2007 Thermo Fisher Scientific Inc. All rights reserved. Al/ trademarks are the property of Thermo Fisher Scientific Inc. and its subsidiaries. Specifications, terms and pricing are subject to change. Not all products are available in all countries. Please consult your local sales representative for details. AN10132E09/07C Thermo 残余溶剂 (VOC) 的存在会严重地影响产品的质量;为了防止在产品的最终包装材料中出现过量的残余溶剂,在整个过程中实施有效的在线控制是必需的。

关闭-

1/3

-

2/3

还剩1页未读,是否继续阅读?

继续免费阅读全文产品配置单

赛默飞色谱与质谱为您提供《包装材料中VOC检测方案(气相色谱仪)》,该方案主要用于包装中VOC检测,参考标准《暂无》,《包装材料中VOC检测方案(气相色谱仪)》用到的仪器有赛默飞Trace1300E 气相色谱仪。

我要纠错

推荐专场

气相色谱仪(GC)

更多相关方案

咨询

咨询