进口

美国Hummingbird是电镜业内最知名的原位透射应用厂家,至今已经有10年的原位透射应用研发经验,蜂鸟来源于最著名的美国柏克林国家实验室,其专利的技术如液体杆,气氛反应样品杆,加热样品杆等都得到电镜工作者广泛的认可。

Overview

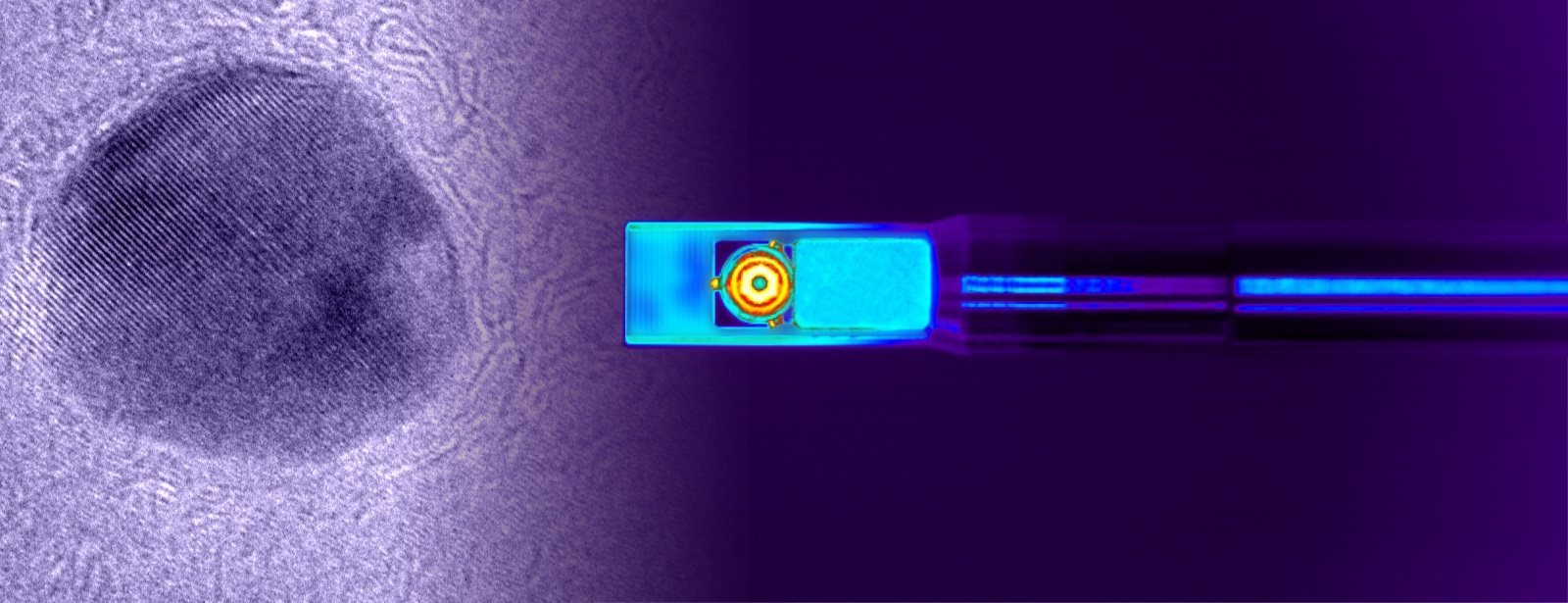

Hummingbird Scientific’s in-situ Bulk Heating Holder 1500 series has been thermally optimized for low power input and minimal sample drift, enabling high temperature experimentation in both ETEM and standard TEM applications. It utilizes unique, high performance materials and innovative thermal management approaches to allow rapid acquisition of atomic resolution images at elevated temperatures. It is compatible with both traditional high vacuum TEM experimentation, as well as demanding ETEM experiments in oxidizing and reducing environments.

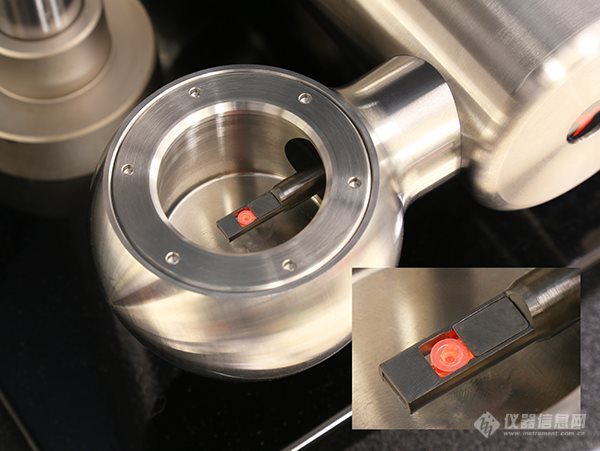

How It Works

Hummingbird Scientific in-situ heating holder utilizes optimized material and geometric choices for the best mechanical and thermal performance during operation of this resistive heating holder.

?Non-magnetic furnace material – critical for aberration-corrected experiments ?Designed for challenging ETEM environment ?Direct thermocouple measurement of sample temperature ?Low thermal drift after stabilization ?No water cooling required ?Closed loop control software

Software

The Series 1500 Heating Holder includes a stand-alone heating controller box that is USB compatible. The included simple to use control software allows for effective control, ramping functions and data collection.

Software Features Include

?Sample temperature control in both closed loop and open loop mode ?Full data-logging and display High Resolution photo mode

Accessories

Accessories available to maximize the use of your Magnetizing Holder. High temperature sample grids

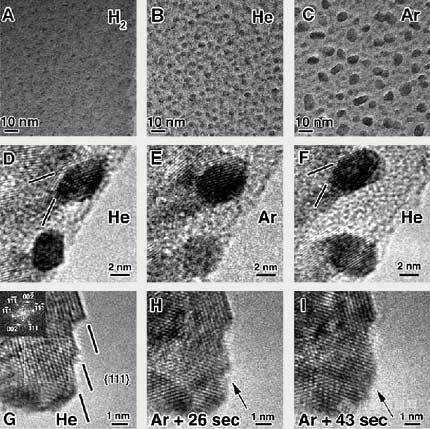

In-situ TEM Catalysis

Right: Study of microstructural changes as a function of the gas environment of an Fe catalyst as shown by sequential high-resolution transmission electron micrographs:

(A to C) Size evolution of Fe catalysts after 60 min under H2 (A), He (B), and Ar (C) at 500°C and 500 mtorr.

(D to F) Series of images from the same two Fe catalyst particles held at 500°C, as the gas overpressure is changed from (D) 500 mtorr He to (E) 500 mtorr Ar to (F) 500 mtorr He.

(G to I) Series of images from a larger Fe catalyst particle along a 110 zone axis:

(G) Image taken in 500 mtorr He at 500°C, showin very strong {111} facets. The inset diffractogram confirms the zone axis orientation.

(H) After the introduction of Ar, local degradation of the facets begins.

(I) With further time at 500°C in the Ar environment, the facet has been completely removed.

For all cases, the H2O with base pressure of 10-2 mtorr is present. Arrows in (H) and (I) indicate the gradual defaceting features over time.

Specification:

1500 Series | ETEM | TEM |

Max Operating Temperature | 800°C | 1000°C |

Settled resolution at 800°C | Up to TEM resolution | Up to TEM resolution |

Temperature Measurement | Direct Thermocouple | Direct Thermocouple |

Tilt Range | Up to ±45° depending on objective pole | Up to ±45° depending on objective pole |

Cooling at High Temperatures | Passive Conduction (No Liquid Cooling) | Passive Conduction (No Liquid Cooling) |

Furnace Material | 3 or 4 contact | 3 or 4 contact |

Heating Temperature | Non-Magnetic and Chemically Inert | Non-Magnetic and Chemically Inert |

TEM Compatibility | FEI, JEOL, Hitachi, Zeiss | FEI, JEOL, Hitachi, Zeiss |

- 相关仪器

相关产品

仪器对比

仪器对比

关注

关注