方案详情文

智能文字提取功能测试中

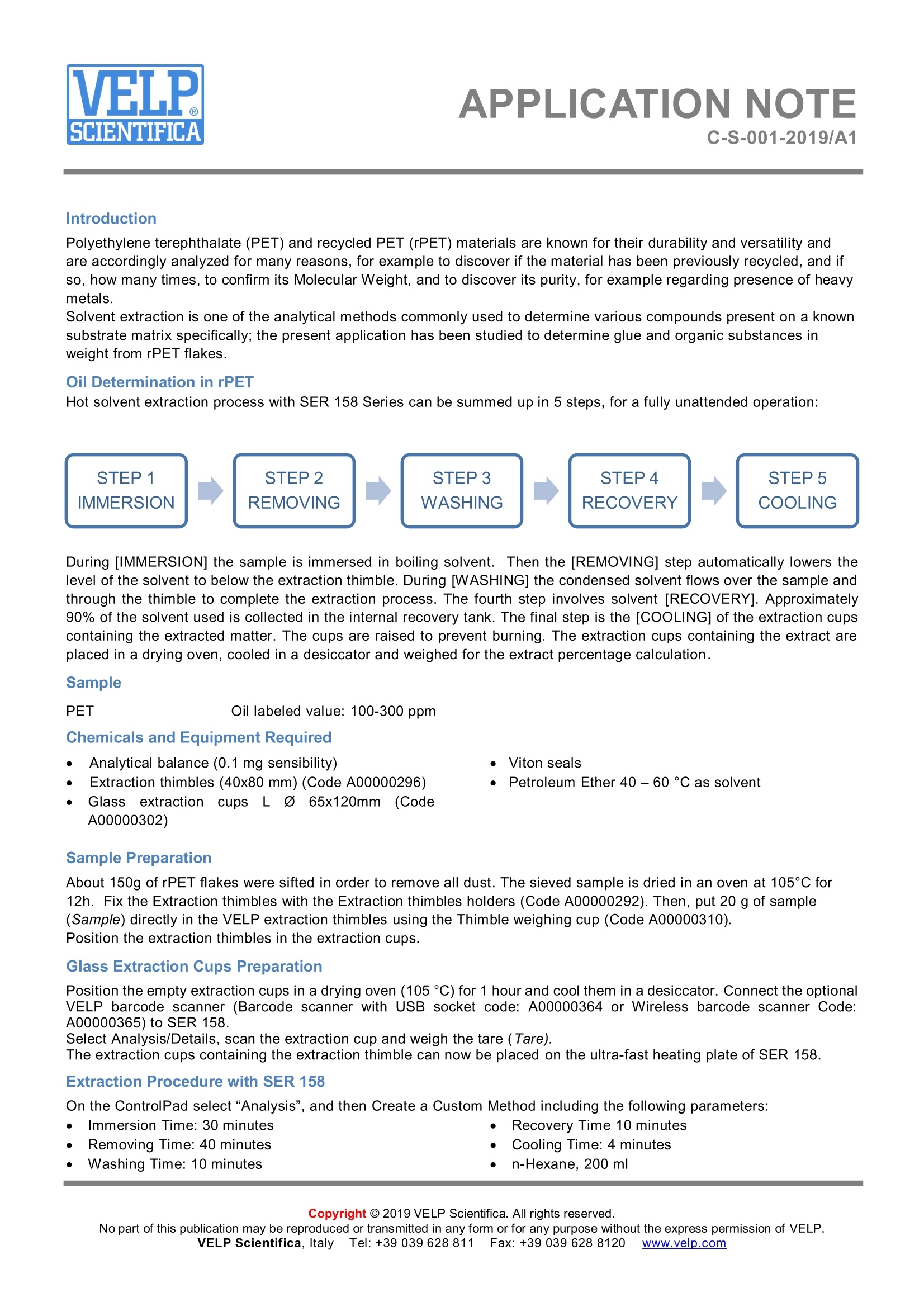

APPLICATION NOTEC-S-001-2019/A1 APPLICATION NOTE Oil Determination in Recycled PETaccording to the Randall method Reference: Velp Internal Procedure Tested with VELP Scientifica SER 158/6 Solvent AutoExtractor (Code S303A0380) C-S-001-2019/A1 Introduction Polyethylene terephthalate(PET) and recycled PET (rPET) materials are known for their durability and versatility andare accordingly analyzed for many reasons, for example to discover if the material has been previously recycled, and ifso, how many times, to confirm its Molecular Weight, and to discover its purity, for example regarding presence of heavymetals. Solvent extraction is one of the analytical methods commonly used to determine various compounds present on a knownsubstrate matrix specifically; the present application has been studied to determine glue and organic substances inweight from rPET flakes. Oil Determination in rPET Hot solvent extraction process with SER 158 Series can be summed up in 5 steps, for a fully unattended operation: During [IMMERSION] the sample is immersed in boiling solvent. Then the [REMOVING] step automatically lowers thelevel of the solvent to below the extraction thimble. During [WASHING] the condensed solvent flows over the sample andthrough the thimble to complete the extraction process. The fourth step involves solvent [RECOVERY]. Approximately90% of the solvent used is collected in the internal recovery tank. The final step is the [COOLING] of the extraction cupscontaining the extracted matter. The cups are raised to prevent burning. The extraction cups containing the extract areplaced in a drying oven, cooled in a desiccator and weighed for the extract percentage calculation. Sample PET Oil labeled value: 100-300 ppm Chemicals and Equipment Required ●·AAnalytical balance (0.1 mg sensibility) Viton seals ● Extraction thimbles (40x80 mm) (Code A00000296) Petroleum Ether 40 -60°C as solvent GlassextractioncupsLL o65x120mmn(CodeA00000302) Sample Preparation About 150g of rPET flakes were sifted in order to remove all dust. The sieved sample is dried in an oven at 105°℃ for12h. Fix the Extraction thimbles with the Extraction thimbles holders (Code A00000292). Then, put 20 g of sample(Sample) directly in the VELP extraction thimbles using the Thimble weighing cup (Code A00000310). Position the extraction thimbles in the extraction cups. Glass Extraction Cups Preparation Position the empty extraction cups in a drying oven (105℃) for 1 hour and cool them in a desiccator. Connect the optionalVELP barcode scanner (Barcode scanner with USB socket code: A00000364 or Wireless barcode scanner Code:A00000365) to SER 158. Select Analysis/Details, scan the extraction cup and weigh the tare (Tare). The extraction cups containing the extraction thimble can now be placed on the ultra-fast heating plate of SER 158. Extraction Procedure with SER 158 On the ControlPad select“Analysis", and then Create a Custom Method including the following parameters: ●Immersion Time: 30 minutes Recovery Time 10 minutes ● Removing Time: 40 minutes Cooling Time: 4 minutes ● Washing Time: 10 minutes ● n-Hexane, 200 ml Close the safety guard and add the solvent using the automatic solvent dispensing system SolventXpressTM to minimizeexposure to the solvent ensuring operator safety. Press START to begin the extraction process. At the end of analysis position the extraction cups containing the extract in a drying oven (1 hour at 105C), cool them ina desiccator to room temperature. In Results menu select the extraction cups batch ID analyzed, press calculate, scan the extraction cups with barcodereader and weigh (Total). Results on rPET Analysis results are calculated automatically and stored in the ControlPad when entering the weights into the software(manually or automatically through a balance). The extract percentage calculation is performed by using the followingformulas: Where: Sample= sample weight (g) Tare=weight of the empty extraction cup (g) Total= weight of the extraction cup +extract (g) Sample (g) Tare (g) Total (g) Extract (%) 20.4255 143.9636 143.9696 0.020% 20.5575 140.7315 140.7376 0.020% 20.0279 144.0568 144.0619 0.015% 20.5465 140.7318 140.7369 0.015% 20.5284 143.9632 143.9687 0.017% 20.2864 143.9634 143.9687 0.016% Average±SD% 0.017±0.002 Oil Labeled Value:100-300 ppm (0.01-0.03%) Conclusions The results obtained are reliable and reproducible in accordance with the expected values, especially considering thelow amount of Oil in this matrix. Therefore, SER 158 Solvent Extractor is ideal for the Oil Determination in RecycledPET. Benefits of hot solvent extraction (Randall) by using SER 158 Automatic Solvent Extractor: up to 5 times faster than Soxhlet (hot solvent vs. cold solvent) ● Iow solvent consumption (high solvent recovery, approximately 90%)-limited cost per analysis ● no exposure to solvent ● worldwide official method full traceability with automatic result calculation and on-board archive Cloud connectivity to VELP Ermes ensuring software updates, real time monitoring and control, notifications and enhancedservice support. Copyright C VELP Scientifica. All rights reserved.No part of this publication may be reproduced or transmitted in any form or for any purpose without the express permission of VELP.VELP Scientifica, Italy Tel:+ Fax: + www.velp.com 利用SER158全自动溶剂萃取仪做塑料品种的化学残留样本前处理:聚对苯二甲酸乙二酯(PET)和回收的PET(rPET)材料以其耐用性和多功能性而著称,因此出于许多原因进行了分析,例如发现该材料先前是否已回收,如果发现,则进行多少次,以确认其用途。 溶剂萃取是通常用于确定已知基质基质上存在的各种化合物的分析方法之一。本应用指南研究了PET塑料种薄片中分析化学残留含量。

关闭-

1/3

-

2/3

还剩1页未读,是否继续阅读?

继续免费阅读全文产品配置单

意大利VELP公司为您提供《塑料制品中化学残留检测方案(快速溶剂萃取)》,该方案主要用于其他中含量分析检测,参考标准《暂无》,《塑料制品中化学残留检测方案(快速溶剂萃取)》用到的仪器有null。

我要纠错

相关方案

咨询

咨询