方案详情文

智能文字提取功能测试中

◎ 2003, Tinius Olsen 10/03 1M 03-262 Printed in U.S.A. Bulletin136 Tinius Olsen F SeriesMachines Tinius Olsen, one of the orldosleading manufacturers of materialstesting machines, offers a machines pecificallyfor analyis of foodtetur es. The F series food tetur eanalgr is a simple, accurate,fleible, and poerful machine thatis ideallyused for common tekur etests such as TPA, puncture, backetrusion, deformation, snap,puncture, shear, etrusion and r elatedtests on applications up to 200 lbf(1 kN). Fig 1. Food tester being cleaned ih ater aftertesting. The surgicalgrade stainless steelconstruction of the foodtester makes thispossible ihoutdamaging the machine. The machine can be fitted ith aarietyof speciallyengineer ed grips,probes, and cells, specificallyengineered for testing food. Whencombined ih our poerful testingsofter e, the res ultant sytembecomes a fleible et r obust testingstation that is designed around theunique needs of the food industries. While the F Series machine is specifically designedfor the intricacies testing food, it can also take advantageof the rest of Tinius Olserisduct offering and canuse gips that are commonly usetesding foodpackaging.oditionally, test routines that are used for testingpackaging, from frictional testing to compression or teartesting, are availalimethe PC based software. Fig 2. Food testingmachine show ithWarner B ratler shearcell. The machine iscontrolled directlyfrom a PC ith onlythe basic crossheadcontrols agilable onthe machine. shuses Key Features ¥ Surgical grade stainless steel con-struction allows for quick and easyhose down and cleaning. ¥PC control via high speed RS 232using AS Cll mode and our propri-etary super high speed binarymode. ¥Machines are proof loaded to 200%of capacity. ¥Force accuracy of 0.5% of appliedload across the load cell dis playrange. ¥ B uilt in intelligent active force anddis placement alarm system. ¥32 bit precision motor controller. ¥ Displacement resolution of0.0001 mm (in binary mode). ¥S peed resolution of 0.001 mm/min. ¥150% mechanical overload capacityon each interchangeable load cell. ¥20% digital tare while maintainingfull load cell capacity. ¥Automatic motor drive alarms thatmonitor over/under voltage, current,and temperature. Features of singlec olumn machines ¥PC control via high speed RS 232using AS CII mode and super highspeed binary mode. ¥Forceaccuracy of 0.5% of appliedload across the load cell dis playrange. ¥Built-in intelligent active force anddis placement alarm system. ¥32 bit precis ion motor controller.¥Displacement resolution of 0.0001 mm. ¥ S peed resolution of 0.001 mm/min.¥150% mechanical overload. Technical S pecific ations MODEL CAPACITY lbfkNkg H1K 200 1 100 MAXIMUM SAMPLEDIAMETER inmm 6150 LOAD CELLS Rapid change, Z beam, load cells with digital encoding forautomatic recognition and scaling available N1 kN, 500 N, 250 N, 100 N, 50 N, 10 N, 5 N MAXIMUM CROSSHEAD TRAVEL (excluding grips) inmm Measurement direct from ballscrew Nfully auto scaling of single meas urement range17.5445 in/minmm/min 0.00004 to 40 up to 100 lbf, 0.00004 to 20 up to 200 lbf0.001 to 1000 up to 500 N, 0.001 to 500 up to 1 kN JOG SPEED in/minmm/min 0.00004 to 400.001 to 1000 RETURN SPEED in/minmm/min 0.00004 to 40 0.001 to 1000 DIMENSIONS HxWx D in mm 32x14x14820 x 360 x360 WEIGHT lbkg 5525 ¥ Automatic motordrive alarms thatmonitor over/undervoltage, current,and temperature. Fig 3 Puncture probes are us ed tode termine the ripeness of va rious fruits. be tes ted, such as the toma toesHe re you can see the s imple collection s hown here, and any s pra y fromtra y a fte r te s ting s ome ripe wa te rmelon the samples can be s imply wa s he d Fig 4 Both fruts and ve ge ta bles can off. Fig5 Large and s ma ll fruits andvege tables can be tes ted on the s a mplete s t pla tform. This pla tform has a holedins e rt ta ble wh a product colle ctiontra y loca te d unde rne a th. Fruits and egetables Magnusylor Punctue PobeThe complete Magnus Taylor PunctureProbe set comprises two sets of twocylindrical probes with diameters of8 mm and 11 mm; one probe has ahemis pherically domed end and theother has a flat end. A familiar drillchuck is supplied within which theselected probe is fixed, along with thebase support. Additionally, eight flatend probes are supplied that havediameters starting at 1.6 mm andincreasing in diameter increments of1.6 mm up to a maximum of 12.8 mmdiameter. Texture Pobe SetSimilar to the Magnus Taylor Punctureprobe set, the Texture Probe setcomprises a series of flat ended cylin-drical probes of various diameters.A drill chuck is provided to mount anindividual selected probe. The setcomprises seven probes which rangein diameter from 0.06 Back Extrusion CellThe back extrusion cell is ideal fortesting fruits, vegetables, and doughswhose consistency or stickinesswould cause a forward extrusion cellto become easily blocked. The princi-ple of operation is to compress thefood with a circular pis tonwhose diameter is smallerthat the inside diameter ofthe cylinder in which thefood is placed. The com-pression action forces thefood to be extruded backover the pis ton through thering created between thepiston and cylinder. Fourpistons with diameters of34, 36, 38 and 39.9 mm areprovided along with the containmentcylinder, whichhas an insidediameter of40 mm. Fig 6 and 7 Before and aftershots of an aubergine (egqplant)being tested with a textureprobe to determine the skin strength. Screen 1. An example of thetest profile of processedpeas being tested ina back extrusion cell. inches to 0.5 inches. Fig 8. Ottowa ForwadExtrusion UnitThe Ottowa Extrusionunit is ideal for foodproducts that use anextrusion process intheir manufacture, suchas pie fillings, beans,and snack foods. Theunit consists of a squarepiston and cell,and a series of fourinterchangeable platesthat are either perforat- ed or slotted. Foods are extruded through these different plate types inthe course of a compression type test. Fig 8 and 9. Before and after shotsof a back extrusion cell being used todetermine the consistency of peas. Fig 10. Me ats Warner Bratzler Shear CellThe Warner Bratzler S hear Cell isideal for meats and vegetables andsimulates cutting and slicing. Thecell comprises four interchangeableplain V shaped shear blades andappropriately sized and guided baseplate. The four blades have differentV angles of 30j, 50j, 60j and 70j. Kramer Shear Cell. The Kramer Shear Cell is ideal fortesting the texture of meats, fruits,and vegetables by determining theshear and extrusion forces as a tenbladed compression unit passesalong guides, through the food,and out through the appropriatelyslotted base. This fixture is ideal fordetermining the texture of meatsand other food products such as piefillings, baked beans, coleslaw,and prepared salads. of a frankfurter being sliced in a Warner Bratzler 12 PASS 001 45 00 2554 20 15 12 12 Fig 13. Screen 2 Test profile of some cat foodbeing tested in a Kramer Shear Cell. Fig 12. Fig 12 and 13 Before and after shots ofcat food being checked with a Kramer Shear Cell. DairyPoducts Food exture PobesTinius OIsen has a variety of standardfood texture probes that can beattached to the machine. Theseconical or spherical probes come in avariety of sizes and are typically usedwith dairy or gelatin based products. Conical Pobes Conical probes come in a variety ofangles, including 15j, 30j, 45j, 60j,and 90j, and are ideal for determiningthe spreadability of dairy productsand spreads. Ball Pobes Ball probes come in a variety ofdiameters and are typically used todetermine product softness. The keyprinciple employed is that the ballprobe exerts a compressive force thatis applied at a normal angle to allparts of the surface. Diameters ofavailable ball probes include metricsizes of 2 mm, 4 mm, 6 mm, 8 mm,and 10 mm, and English sizes of 1/40,1/2O, 3/4O, and 10. OPTA-TPA PA Yie 中 lPate ne88 ha 42.0 34.0 1TenDe 26.0 Stinginess Screen 3 .Texture profile of aball probe being inserted insome jelly and then removed raph Foint 18.0 Fi F1_F P1_F2 P1 A1 10.0 Fist llAi 2.0 L2 5ecoond Penethraicr 6.0 P2_F2 P2A1 P2_L1 Second y/thdiewa -14.0 W2AT W2L1 -22.0 -- 1.5 3.0 4.5 6.0 7.5 90 105 12.0 13.5 secs 5.0 Fig. 16 and 1Before and after photos of a ball probe being used to determinethe softness of a gelatin based pudding. PeclomTes StartTESTZONE-Micros H Qmat Crispness o... Food Testing Software Tinius Olsen Food Testing S oftware is supplied with various routinesfor food testing such as: American Ins titute of Baking; Bagels Agar Gel Deformation Apple Puncture Apple Sliced DExtrusion Shear Beans (Cooked) DPuncture Beans (Raw) DPunctureBeans (Raw) DBack ExtrusionBeans (Canned) DBack Extrusion Beet DBack Extrusion Beet D Deformation Bun DDeformation Rock Candy DDeformation Carrot(Raw) DDeformation Carrot (Raw) DPuncture Carrot (Canned) DBack Extrusion Cheese DPuncture Cherry Pie Filling DBack Extrusion Chocolate Bar DSnap Cookies/Bis cuits D S nap Egg (Whole) DDeformation Frankfurter DDeformation Marshmallow DDeformation Onions (B oiled) DPuncture Green Peas (Raw) D Multiple Puncture Tofu (Curd) DPunch Turkey R oll (S liced) D Tensile etc. tinius Olsen has a Test Generator from whichseveral test methods can be chosen, forins tance TPA, Deformation, Extrusion, Bend, 号File E: Eicportiea Startamat 4.02-Dongl. File Examination... 能图鸡”51210:27AM Within each, the user can select a variety of results and testparameters that can be saved and used whenever required. Withinthe selection for TPA, the standard results such as Adhesiveness,Chewiness, and Fracturability (brittleness), can be chosen. A Post Test Module can be used to interrogate the data to modifyor calculate new res ults. For TPA, the post test analysis sectionallows the user to define their own areas, force points, dis placements(as mm or seconds) and then use these to build their own formulae inconjunction with the standard areas and forces normally used. Theseformula macros can be saved and re-used as required. 1065 Easton RoadHorsham, PA 19044 USA(215) 675-7100Fax (215) 441-0899www.TiniusOlsen.com info@TiniusOlsen.com 6 Perrywood Business ParkHoneycrock Lane, S alfordsRedhill, S urrey RH1 5DZ England+44 (0) 1737 765001Fax +44 (0)1737764768

关闭-

1/8

-

2/8

还剩6页未读,是否继续阅读?

继续免费阅读全文产品配置单

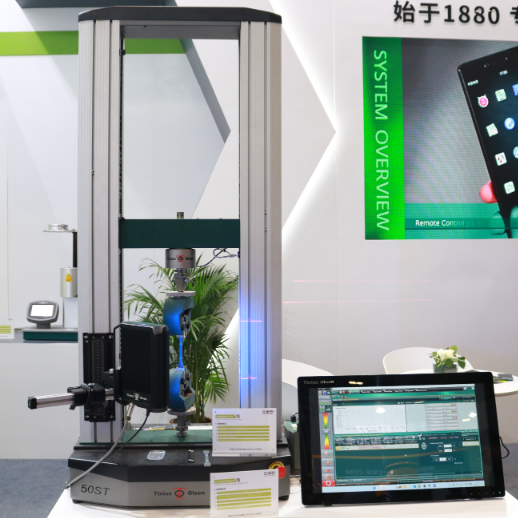

美国TO为您提供《食品中力学检测检测方案 》,该方案主要用于食品中力学检测检测,参考标准《暂无》,《食品中力学检测检测方案 》用到的仪器有Tinius Olsen天氏欧森50ST电子万能试验机、Tinius Olsen天氏欧森5ST电子万能试验机。

我要纠错

相关方案

咨询

咨询