方案详情文

智能文字提取功能测试中

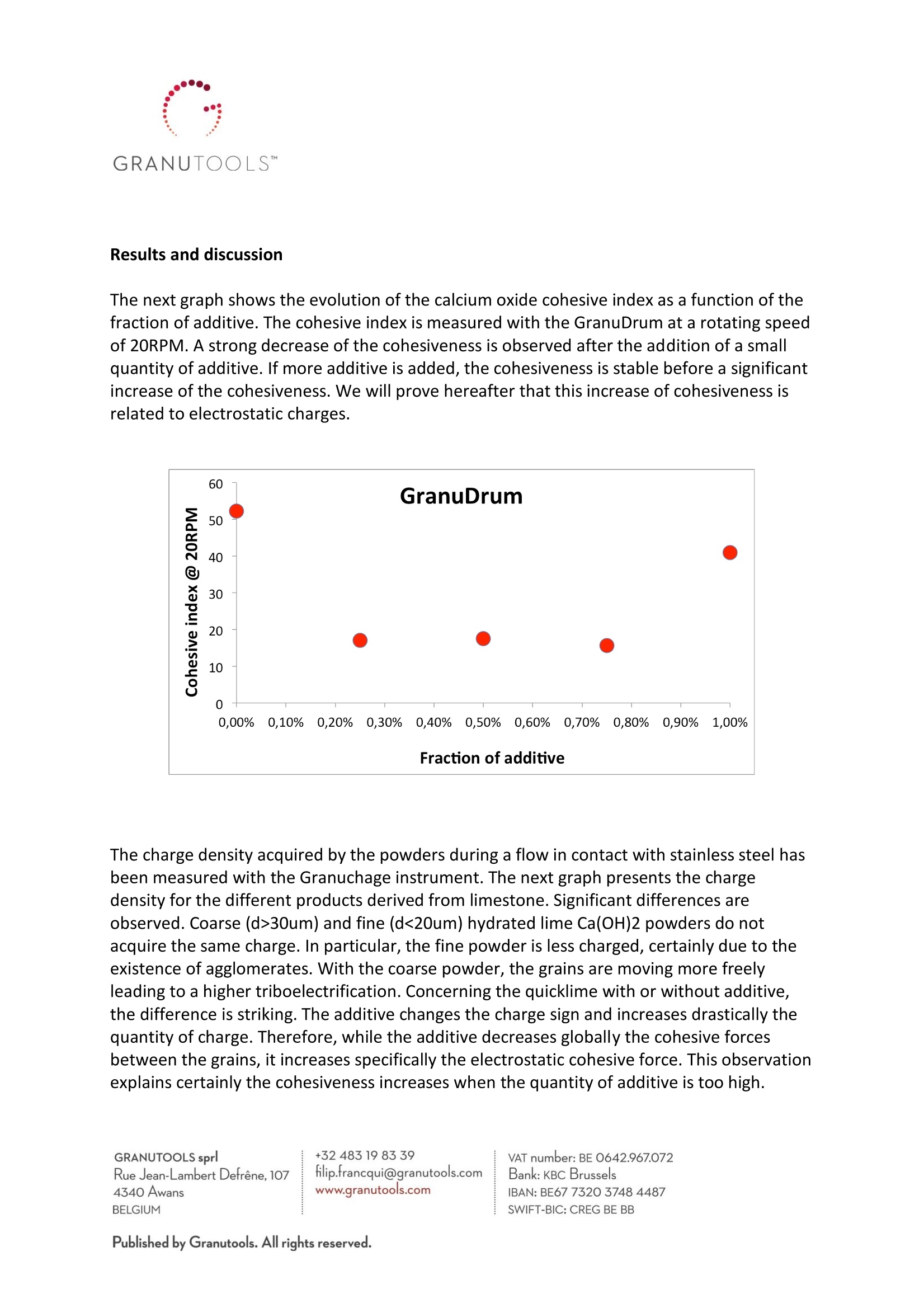

GRANUTOOLS" Application note:Electrostatic and flowing properties of limestone and lime powders using GRANUCHARGETMGRANUDRUMTM Introduction Limestone (Calcium carbonate) powders and the derivative products are extensively used inthe construction industry, in chemical and metallurgical industries and also in agriculture.These powders are highly cohesive and additives are commonly used to enhance theirflowability. The additive and the quantity of additive have to be carefully chosen to optimizeproduction processes. In this case, glycol-type additive was used. In the present application note, we show how the GranuDrum instrument can be used toquantify the effect of flow enhancer additives. Moreover, the GranuCharge instrument isused to study the electrostatic properties of the powders. Different limestone derivateproducts have been considered: Calcium carbonate CaCO3 (Limestone), Calcium hydroxideCa(OH)2 (hydrated lime) and Calcium oxide Cao (quicklime). The main forces inducing cohesiveness in powders are van der Walls force (always present atthe contact between two solids), capillary force (related to the water content), electrostaticforce. Therefore, the apparition of electrostatic charges inside a powder due to thetriboelectric effect can increase powder cohesiveness. Therefore, in addition to thecohesiveness measurement preformed by the GranuDrum, a GranuCharge electrostaticmeasurement allows to predict more precisely the behaviour of the powder inside theprocess line. Results and discussion The next graph shows the evolution of the calcium oxide cohesive index as a function of thefraction of additive. The cohesive index is measured with the GranuDrum at a rotating speedof 20RPM. A strong decrease of the cohesiveness is observed after the addition of a smallquantity of additive. If more additive is added, the cohesiveness is stable before a significantincrease of the cohesiveness. We will prove hereafter that this increase of cohesiveness isrelated to electrostatic charges. The charge density acquired by the powders during a flow in contact with stainless steel hasbeen measured with the Granuchage instrument.The next graph presents the chargedensity for the different products derived from limestone. Significant differences areobserved. Coarse (d>30um) and fine (d<20um) hydrated lime Ca(OH)2 powders do notacquire the same charge. In particular, the fine powder is less charged, certainly due to theexistence of agglomerates. With the coarse powder,the grains are moving more freelyleading to a higher triboelectrification. Concerning the quicklime with or without additive,the difference is striking. The additive changes the charge sign and increases drastically thequantity of charge. Therefore, while the additive decreases globally the cohesive forcesbetween the grains, it increases specifically the electrostatic cohesive force. This observationexplains certainly the cohesiveness increases when the quantity of additive is too high. It is well known that small water content in powders decreases the electrostatic forces. Indeed, the presence of water increases drasticallythe powder electrical conductivity,leading to a dissipation of the electrostatic charges. This effect has been quantified with theGranuCharge instrument. The next graph show the charge density measured after a flow incontact with stainless steel (i) for a sample of hydrated lime with a water content of 0,4%and (ii) for the sample after a drying process. The triboelectrification is multiplied by a factor6 after the drying process. BELGIUM SWIFT-BIC: CREG BE BB Conclusion The GranuDrum flowmeter is able to determine the optimal quantity of flow-enhanceradditive for limestone and the derivative products. Moreover, the analysis performed withthe GranuCharge powder-triboelectrometer, allows understanding more precisely themechanisms behind the cohesiveness. In particular, when the quantity of additive is toohigh, the powder becomes sticky due to the apparition of electric charges. Finally, the effectof the water content on the electrostatic charge has been demonstrated. References Measuring the flowing properties of powders and grains, G. Lumay, F. Boschini, K. Traina, S.Bontempi, J.-C. Remy, R. Cloots, and N. Vandewall, Powder Technology 224, 19-27(2012) http://www.essentialchemicalindustry.org/chemicals/calcium-carbonate.html GRANUTOOLS sprl + VAT number: BE ue Jean-Lambert Defrene, filip.francqui@granutools.com Bank: KBC BrusselsAwans www.granutools.com IBAN: BEELGIUM SWIFT-BIC: CREG BE BBPublished by Granutools. All rights reserved. GRANUTOOLS sprl + VAT number: BE ue Jean-Lambert Defrene, filip.francqui@granutools.com Bank: KBC BrusselsAwans www.granutools.com IBAN: BEELGIUM SWIFT-BIC: CREG BE BBPublished by Granutools. All rights reserved. 石灰石(碳酸钙)粉及其衍生物广泛应用于建筑业、化工、冶金工业以及农业。这些粉末具有高粘性,添加剂通常用于增强其流动性。添加剂和添加剂的添加量必须仔细考量,以优化生产过程。在此研究中,使用了乙醇型添加剂。在目前的应用说明中,我们展示了如何使用颗粒测量仪来量化流动增强剂添加剂的效果。此外,还利用颗粒电荷仪对粉末的静电性质进行了研究。考虑了不同的石灰石衍生产品:碳酸钙CaCO3(石灰石),氢氧化钙Ca(OH)2(水化石灰)和氧化钙CaO(生石灰)。引起粉末内聚性的主要力有范德华力(在两个固体接触时总是存在)、毛细力(与含水量有关)和静电力。因此,摩擦电效应导致粉末内部静电电荷的出现可以增加粉末的内聚性。因此,除了由颗粒预先形成的粘结性测量,颗粒电荷静电测量允许更精确地预测粉末在工艺线内的行为。

关闭-

1/4

-

2/4

还剩2页未读,是否继续阅读?

继续免费阅读全文产品配置单

大昌华嘉科学仪器为您提供《石灰石和石灰粉中静电和流动特性检测方案(粉末流动性)》,该方案主要用于石灰/石膏及其制品中静电和流动特性检测,参考标准《暂无》,《石灰石和石灰粉中静电和流动特性检测方案(粉末流动性)》用到的仪器有粉体静电吸附性能分析仪 Granucharge、粉体休止角分析仪 Granuheap。

我要纠错

推荐专场

粉末流动性测试仪

更多相关方案

咨询

咨询