第1楼2005/04/02

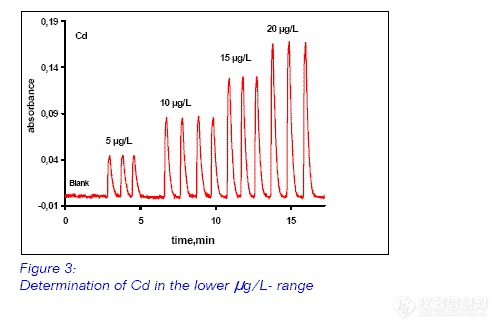

The experiments showed that a beam is stable over a

distance of at least 15 cm if its speed is higher than

about 12 m/s. Using a nozzle of 50 :m inner diameter,

a 1.42 mL/min flow rate is necessary to reach this

speed. The typical shape of a smooth jet nozzle is a

cylinder with a ratio length/diameter > 3. The pressure drop of such a nozzle is less than 0.5 bar which

allows the use of low-pressure pumps, for instance a peristaltic pump, for the beam generation.

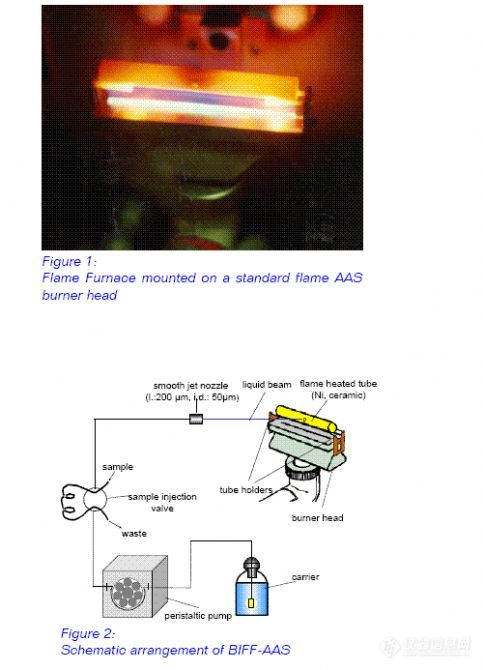

The requirements for the material of the tube furnace include good stability and chemical resistance

against the corrosive conditions of an acetylene/air flame and water and acid vapors at temperatures higher

than 1000 /C.

Suitable tube materials are pure nickel, super alloys or non-porous Al2O3 ceramic. To increase the

temperature inside the furnace and to achieve a more reducing atmosphere, a tube with 4 or more

additional holes located on the bottom side is used.

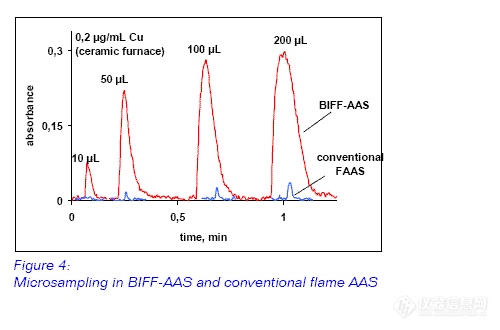

Currently, 25 elements have been determined

using BIFF-AAS, of which 17 elements (Ag, As,

Au, Bi, Cd, Cu, Hg, In, K, Pb, Pd, Rb, Sb, Se,

Te, Tl, Zn) exhibit an improved power of

detection from 6 fold to 202 fold compared to

conventional FAAS [1]. The standard deviation

amounts to 1.7 - 4.0 % (N = 12; 50 :L

samples). Fig. 3 shows the signals of Cd sample

in the low :g/L range measured with BIFFAAS.

第2楼2005/04/02

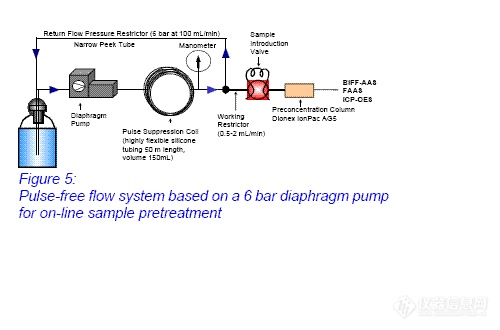

The sample is injected via a sample introduction

valve into a carrier stream as in all flow injection

techniques including HPLC. Because of this,

even sample volumes as small as 10 :L can be

easily applied. Fig. 4 shows the determination of

copper with increasing sample volumes and

using BIFF-AAS as well as conventional flame-

AAS. With 10 :L samples a clear Cu signal

appears in case of BIFF-AAS but not when

using the normal flame AAS. Working with a

peristaltic pump allows a continuous sample

introduction to be maintained. Generating the

liquid jet with the aid of a high-pressure pump,

BIFF-AAS can be applied as a simple, efficient

interface between HPLC separation techniques

and elemental determinations by flame-AAS.

第3楼2005/04/02

To fill the gap in the pressure range between

HPLC and peristaltic pumps a novel pump

system based on a 6 bar low cost diaphragm

pump has been developed (Fig. 5). The unavoidable

strong pulsation has been overcome by

using 50 m (2 mm i.d.) of highly flexible silicone

tubing as a pulse suppression coil. This results

in a smooth pulse free continuous flow whereby

the pump delivers 100 ml/min in circulation. For

analytical flow injection a restrictor is connected

to a splitting point in the cycle to tap off the

flow needed, down to 0.2-5.0 ml/min. The

higher pressure of the diaphragm pump

compared to the peristaltic pump permits the

use of common HPLC-columns or low-pressure

chromatography columns for online-sample

pretreatment like preconcentration of traces or

matrix separation. This system was successfully

applied for the beam generation in BIFF-AAS

and for on-line sample pretreatment in

conventional AAS and ICP-OES respectively.