第1楼2005/03/30

Additional Transpiration Studies:

The next study was conducted for LDPE bottles of 30, 125, 250, and 500 mL capacity. The purpose was to determine if the correlation of the transpiration rate to the bottle opening held up for a variety of bottle sizes. In addition, other variables were added as illustrated in Figures 6.2 and 6.3.

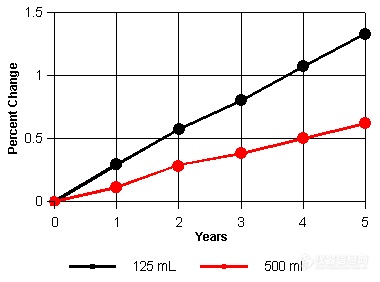

Figure 6.2: Transpiration - 125 ml Bottles

No tape, Never opened

Tape sealed, Never opened

No tape, Opened periodically (30 times)

Tape sealed, Opened periodically (30 times)

No tape, Half-full, Opened periodically (30 times)

Inorganic Ventures' Transpiration Controlled Technology™ (TCT)1

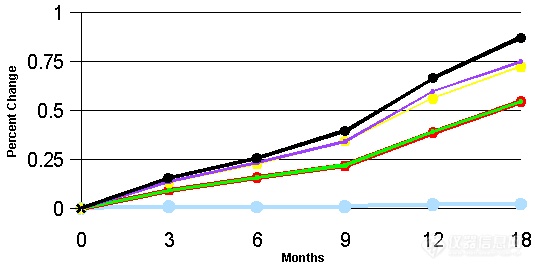

Figure 6.3: Transpiration - 30 ml Bottles

No tape, Never opened

Tape sealed, Never opened

No tape, Opened periodically (30 times)

Tape sealed, Opened periodically (30 times)

No tape, Half-full, Opened periodically (30 times)

Inorganic Ventures' Transpiration Controlled Technology™ (TCT)1

The results for the 250 ml and 500 ml bottles are congruent with the data shown above, with the exception that the transpiration rates are proportionately lower. So the question then becomes, What factor is proportionately effecting the rate of transpiration?

第2楼2005/03/30

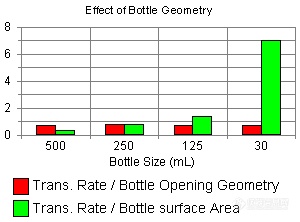

Figure 6.4 shows a comparison of the transpiration rates for all of the bottles capacities as compared to each bottle size surface area. No correlation could be found, indicating that the mechanism for transpiration is not through the bottle walls.

Figure 6.4: Transpiration Rates vs Bottle Surface Area

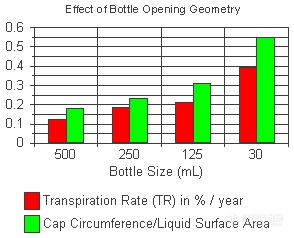

Figure 6.5 shows a comparison of the transpiration rates for all of the bottles as compared to the ratio of the bottle opening circumference to the solution surface area -- i.e. Transpiration Rate vs. [π * dc] ?nbsp;[π * (Rb)2] where:

π = 3.14

dc = cap diameter in centimeters

Rb = radius of bottle (main body)

Figure 6.5: Transpiration Rates vs Bottle Opening Geometry

This study revealed a correlation that fits to within 6 % relative, indicating that transpiration around the cap is the correct mechanism and not through the bottle as previously assumed

第3楼2005/03/30

As additional support for this argument, Figure 6.6 shows a dramatic illustration of the fact that there is a near perfect correlation of transpiration rate to bottle opening geometry and no correlation to the bottle surface area.

Figure 6.6: Bottle Opening vs Area Geometries

Summary of Findings:

Through this study, the following conclusions were drawn:

Transpiration occurs around the bottle opening and not through the bottle as previously thought.

Taping the bottle has no influence upon the transpiration rate.

Bottles that are half full and opened periodically have the highest transpiration rate.

Opening the bottle periodically greatly increases the transpiration rate.

Smaller bottles transpire faster.

30 ml bottles can not have a 1 year expiration date if certified to an uncertainty of ≤ ±0.6 % relative.

Transpiration Controlled Technology™ (TCT)1 totally eliminates transpiration.

Studies involving different bottle construction materials and 'bottle vapor space' have also been conducted and will be published at a later date.

1. Transpiration Controlled Technology (TCT) - a patented technology that virtually eliminates transpiration loss, greatly increasing a standard's shelf life. Developed by Inorganic Ventures for the optimal storage of standards after packaging.